描述

1. 9GQY-3.2 Technical Engineering Specifications

| Technical Feature | 9GQY-3.2 Parameters |

|---|---|

| 工作寬度 | 3200 mm (3.2 Meters) |

| Machine Type | Trailed / Towed Disc Type |

| Tractor Power Requirement | 80 – 120 HP (cv) |

| Conditioning Method | Adjustable Intensity Rollers |

| PTO Input Speed | 540 / 1000 RPM (Selectable) |

| Cutting Disc Speed | Up to 3000 RPM |

| Weight | Approx. 1850 Kg |

2. Five Key Facts About the 9GQY-3.2 Mower Conditioner

- Superior Cutting Width: A full 3.2m working width enables high hectares-per-hour productivity, reducing labor costs for commercial forage producers.

- Integrated Conditioning System: Heavy-duty rubber or steel rollers crush stems to release moisture, accelerating the hay curing process by up to 50%.

- Trailed Stability: The towed configuration provides superior stability on sloped terrains compared to side-mounted units, essential for the mountainous fields of Gangwon-do.

- Hydraulic Control Precision: Equipped with advanced hydraulic folding and height adjustment, allowing operators to adapt to variable soil conditions instantly.

- Manganese Steel Durability: High-resistance cutter bars and discs treated to HRc 52+ hardness ensure long life in abrasive volcanic or stony soils.

3. High-Output Forage Harvesting: The Engineering Edge of 9GQY-3.2

In the rapidly evolving agricultural landscape of South Korea, forage quality is the cornerstone of premium Hanwoo beef and dairy production. The 9GQY-3.2 Mower Conditioner addresses the critical bottleneck of drying time in high-humidity regions. As a specialized mower conditioner manufacturer, Jiujia has engineered the 9GQY series with a high-torque mechanical transmission that maximizes energy transfer from the tractor’s PTO. The 3.2-meter disc cutter bar utilizes a modular design, allowing for rapid blade replacement in the field. Unlike standard mowers, the conditioning rollers on the 9GQY-3.2 are adjustable, allowing operators to vary the conditioning intensity based on crop density and moisture levels. This is particularly vital for the Gyeonggi and Jeju provinces, where soil types vary from heavy clay to volcanic ash. By providing a uniform windrow, the 9GQY-3.2 sets the stage for efficient baling with a forage harvester or square baler, ensuring that the moisture profile remains consistent throughout the stack. Professional growers prioritize this equipment because it minimizes leaf loss in high-value alfalfa while ensuring the tough stems are sufficiently cracked to prevent mold during storage.

4. Regulatory Compliance

Operating high-capacity agricultural machinery in South Korea mandates strict adherence to the Agricultural Machinery Safety Management Act. The 9GQY-3.2 is built to exceed these safety benchmarks, featuring complete PTO shielding and hydraulic safety locks for road transport. Furthermore, South Korean land management construction laws emphasize the prevention of soil compaction and topsoil degradation. The 9GQY-3.2 trailed disc mower conditioner is equipped with high-flotation tires that distribute weight evenly, ensuring that the soil structure in permanent pastures is preserved for future growth cycles.

Globally, this equipment aligns with ISO 4254-1 standards for agricultural machinery safety and environmental stewardship.

In Europe and Australia, regulations regarding noise pollution and the disposal of high-wear manganese steel components are stringent; Jiujia’s manufacturing process integrates recyclable alloy steel and low-noise gear drives to meet these international ESG (Environmental, Social, and Governance) targets. Whether you are a commercial contractor in the USA or a cattle cooperative in Pyeongchang, the 9GQY-3.2 provides the legal and technical assurance required for modern, compliant farming operations.

5. Tractor Compatibility & Replacement Standards

The 9GQY-3.2 is engineered to serve as a high-durability replacement for or complement to global agricultural brands prevalent in South Korea.

| Compatible Tractor Brand | Linkage / PTO Match | 相容性狀態 |

|---|---|---|

| LS Mtron (Korea) | Category 2 Standard / 540 RPM | Perfect Integration |

| TYM / Daedong (Korea) | Category 2/3 / 1000 RPM | Seamless Support |

| John Deere / Kubota | ISO Standard 3-Point / PTO | Universal Fit |

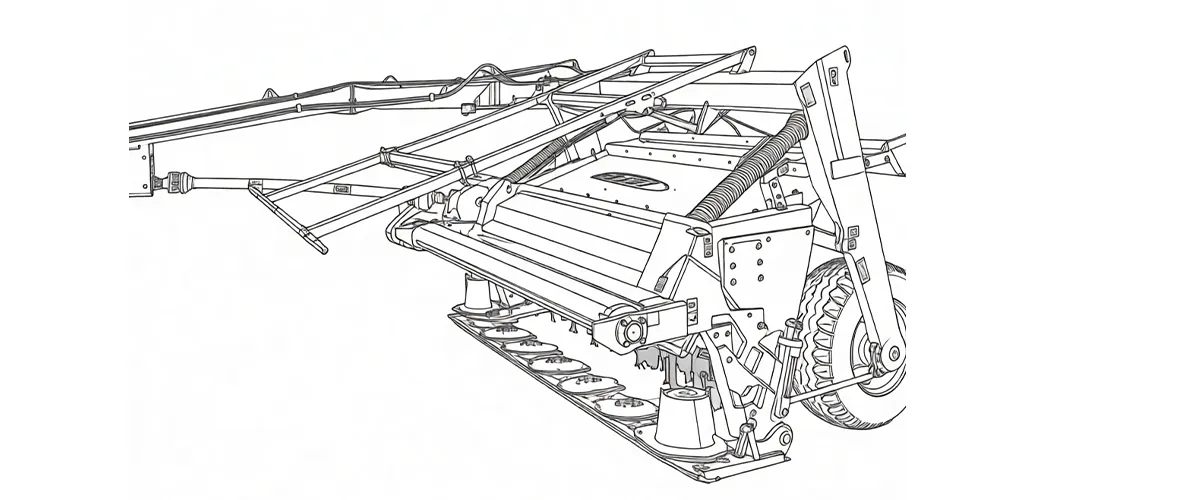

6. Working Principle: Centrifugal Cutting and Mechanical Conditioning

7. Market Trend Analysis: The Future of Forage Harvest in East Asia

The global trend in forage harvesting is moving rapidly toward “One-Pass Efficiency” and “Precision Drying.” In South Korea, the rising cost of imported feed is forcing farmers to produce more high-quality hay locally. We are seeing a significant shift from simple disc mowers to integrated mower conditioners for sale, like the 9GQY-3.2. This is driven by the need to maximize weather windows in unpredictable monsoon climates; reducing field drying time by even 24 hours can be the difference between premium hay and livestock-grade silage. Furthermore, as agricultural robots and GPS-guided tractors become standard, there is an increasing demand for trailed implements that offer predictable tracking and high-speed operation. Jiujia is at the forefront of this trend, integrating sensors for real-time height control and wear monitoring. The demand for mower conditioner manufacturers who can provide local support and parts in South Korea is projected to grow by 12% annually as the Hanwoo industry continues to professionalize its supply chain.

8. Customer Success Case:

Client 1 Profile: South Korea, Gyeonggi-do – Hanwoo Beef Producer

用戶評價:

Client 2 Profile: Australia, Murray-Darling Basin – Large Cattle Farm

用戶評價:

Client 3 Profile: United States, California – Dairy Farm

用戶評價:

Client 4 Profile: New Zealand, Waikato – Sheep and Beef Farm

用戶評價:

Client 5 Profile: Brazil, Mato Grosso – Livestock Feed Production

用戶評價:

9. EVER-POWER Factory: Customization & Quality Assurance

我們的生產基地位於呼倫貝爾經濟技術開發區,佔地超過 32,000平方米 該公司配備了最先進的數控雷射切割機、自動焊接生產線和靜電粉末噴塗生產線。我們不僅是組裝商,更是一家擁有深厚研發能力的綜合製造商。

客製化服務(OEM/ODM): 我們了解不同地區的農業條件有差異。針對韓國市場,我們提供以下客製化選項:

• 水力適應: 調整閥門壓力以配合特定的 LS 或大同拖拉機液壓流量。

• 輪胎升級: 可選配更寬的浮力輪胎,適用於深泥稻田。

• 顏色與品牌: 為經銷商和分銷商提供OEM品牌推廣服務。

我們持有 ISO9001品質管理系統認證 公司已被認定為國家高新技術企業。每台9YG-2.24D打包機在出廠前都要經過嚴格的48小時連續運轉測試,以確保到貨時有零缺陷。

10. Related products

10.1 Gearbox:

相容型號:EP-FK263(方捆打捆機)、EP-RC30 系列(圓捆打捆機,傳動比 1:2,相容於 35mm 6 齒花鍵軸)。應用:將動力輸出軸 (PTO) 動力傳遞至打捆機構,適用於 New Holland 630 或 John Deere 535。參數:扭力 > 500 Nm,20% 節油。選擇此變速箱的理由:尺寸可客製化(可縮小至 250-300 毫米),耐黏性污染物(橡膠煙霧),IP65 防護等級。動力輸出軸:相容型號:EP-PTO 系列(1-3/8″ Z6 花鍵,可調長度 600-1200mm)。應用:連接曳引機和打捆機主驅動裝置,適用於9YG-1.0C型。扭力傳遞效率>95%,相容於SAE/EURO法蘭。適用理由:防水設計,適用於濕式青貯作業;可取代 Weasler 系列。

10.2 鏈條 鏈輪:

相容型號:ANSI 鏈條,附EP鏈輪(節距12.7-19.05mm,滾輪直徑10-12mm)。應用範圍:用於輸送帶或捆紮機構,適用於方捆/圓捆打捆機秸稈輸送。寬度25-40毫米,耐磨鋼材質。適用理由:與 Kobelco 或 HF 集團設備相容,降低鏈條斷裂風險;可提供食品級青貯飼料選項。

10.3 Couplings:

相容型號:EP-Coupling 200 系列(扭力匹配 500-1000 Nm)。應用:連接齒輪箱和打包輥,抑制振動。適用理由:高循環耐用性,相容於 Bondioli 和 Pavesi。

10.4 油壓缸:

液壓缸: EP-HC系列(缸徑50-100mm,行程300-600mm),適用於捆包提升。軸承和密封件:6208-2RS 軸承,L10 壽命 >10000 小時,防塵密封。相容性表格:與 Comer 250T 完全互換(扭矩匹配,價格僅為 35%);法蘭與北美 4 螺栓 PTO 模式匹配。* 免責聲明:以上提及的其他品牌名稱僅供參考。我們不提供這些品牌名稱的原廠產品或設備。* 參數會因工作條件而異,請參考實際圖面。建議選型前確認介面尺寸。

11. Agricultural Professional FAQ

Q1. How much does a professional 9GQY-3.2 trailed disc mower conditioner cost for delivery to South Korea?

A1. The total investment for a 9GQY-3.2 **mower conditioner for sale** depends on your specific customization needs, such as roller material and shipping logistics to Busan or Incheon. To receive a precise **quote** including regional duties and South Korean compliance support, please click our ‘Get a Quote’ button or contact our regional sales office for current **prices**.

Q2. Where can I find a reliable mower conditioner manufacturer that offers local maintenance support in Gyeonggi-do?

A2. Jiujia provides dedicated technical support across South Korea through our network of industrial partners. We offer 24-hour spare parts shipping for the 9GQY-3.2 series, ensuring that your harvest isn’t delayed during the critical cutting window in Gyeonggi-do or Gangwon-do.

Q3. What is the recommended tractor horsepower for operating the 9GQY-3.2 mower conditioner on sloped Korean terrain?

A3. For the best performance on sloped fields typical of rural South Korea, we recommend a tractor with at least 100 HP. This ensures the hydraulic system has sufficient pressure to manage the folding mechanisms while maintaining a consistent 540/1000 RPM PTO speed for high-yield cutting.

Q4. Which conditioning roller material should I choose for high-moisture alfalfa crops in Jeju Island?

A4. For high-moisture alfalfa or leafy forage in Jeju, our high-density rubber conditioning rollers are ideal. They provide a gentle yet effective crimp that breaks the stem without damaging the nutrient-rich leaves, which is essential for premium forage production under the **Farmland Act** quality guidelines.

Q5. How does a trailed mower conditioner compare to a side-mounted disc mower regarding soil compaction?

A5. A **trailed disc mower conditioner** like the 9GQY-3.2 distributes its 1850 Kg weight across its own high-flotation tires. This significantly reduces the vertical load on the tractor’s rear axle compared to mounted units, minimizing soil compaction and promoting healthier regrowth in accordance with South Korean soil stewardship regulations.

Q6. When is the best time to replace the blades on the 9GQY-3.2 to ensure the best hay quality?

A6. To maintain **best potato digger** (comparative industry standard) levels of cutting precision, we recommend inspecting the blades every 50 operational hours. If you notice “ragged” cuts or increased fuel consumption, it’s time to flip or replace the reversible blades. Our modular disc design makes this a 10-minute task.

Q7. Why should I invest in a mower conditioner instead of a standard disc mower for my livestock operation?

A7. A mower conditioner accelerates the drying process by crushing the crop stems. In South Korea’s humid climate, this reduces the risk of mold and allows you to bale hay sooner. Standard disc mowers require the crop to dry naturally, which often takes twice as long and risks exposure to rain.

Q8. What are the legal requirements for agricultural machinery road transport for 3.2-meter implements in Korea?

A8. Implements with a width exceeding 3 meters, like the 9GQY-3.2, require hydraulic folding for road transport. Our unit folds within standard lane widths and includes reflective safety markers and light kits that comply with the **Korean Ministry of Land, Infrastructure and Transport** safety codes.

Q9. How do I adjust the conditioning intensity on the 9GQY-3.2 for different types of forage grass?

A9. Adjustment is simple via a manual or hydraulic tensioning system on the conditioning rollers. For thin-stemmed grasses, you can reduce the pressure; for thick-stemmed alfalfa or sorghum, increasing the pressure ensures the stems are sufficiently cracked for rapid curing.

Q10. Is the Jiujia 9GQY-3.2 compatible with high-capacity forage harvesters from other brands?

A10. Yes, the 9GQY-3.2 is designed to create a uniform, center-discharge windrow that is perfectly matched for pick-up by high-capacity balers or **forage harvester** units from brands like LS Mtron, John Deere, or Claas, ensuring a seamless harvest workflow.

編輯:PXY

*免責聲明:以上提及的其他品牌名稱僅供參考。我們不提供這些品牌名稱的原廠產品或設備。