描述

1. 9GL Series Technical Engineering Specifications

| 不。 | 物品 | 单元 | 规格 |

|---|---|---|---|

| 1 | 型号名称 | / | 9GL-5.0/5.6 Towed Reciprocating Mower |

| 2 | 挂钩类型 | / | Towed |

| 3 | 切割器结构类型 | / | 互惠 |

| 4 | 切割宽度 | 米 | 5 |

| 6 | Grass Cutting Working Width | 米 | 5.6 |

| 7 | 工作速度范围 | 公里/小时 | 6~7 |

| 8 | 生产率 | hm²/h | Forage: 2.4-2.8, Hay: 3.0-3.6 |

| 9 | 平均切割高度 | 毫米 | 60-70 |

| 10 | Matching Power | kW | 30-60 |

| 11 | 功率输出轴转速 | 转/分钟 | 540 |

| 12 | Machine Weight | 公斤 | 1100 |

| 13 | Number of Connectors | 件 | 78 |

| 14 | Hitch Distance | 毫米 | 71 |

| 15 | Machine Dimensions (L × W × H) | 毫米 | 3860 × 5600 × 3000 |

| 16 | Operating Condition | 毫米 | 3860 × 7600 × 850 |

| 17 | 活动叶片数量 | 件 | 68 |

2. Technical Architecture and Material Science

The 9GL-5.0 and 9GL-5.6 series represent the next evolution in integrated hay management equipment, consolidating the mowing and raking processes into a single tractor pass. As a premier Mower/Raker manufacturer, we have optimized these trailed units to maximize hectares-per-hour productivity for professional forage growers. Utilizing high-precision reciprocating mower technology, these machines provide a surgical cut that protects the stem’s vascular structure, promoting faster regrowth compared to traditional rotary systems.

By eliminating the need for a separate raking operation, livestock cooperatives in regions like Gangwon-do and Jeju Island can reduce fuel consumption by up to 35% and minimize soil compaction—a critical factor for sustainable land management in South Korea. These models are engineered for tractors ranging from 45 to 80 HP, featuring a robust folding chassis that ensures a 5.0m to 5.6m working width in the field while maintaining a safe, compact transport profile on public roads.

3. Market Trend Analysis: The Future of Integrated Forage Management

The global agricultural machinery landscape is rapidly pivoting toward “Multifunctional Integration” and “Soil-Centric Productivity.” In South Korea, the rising cost of labor and the consolidation of small family plots into larger commercial cooperatives have driven a 20% annual increase in the demand for wide-swath, 2-in-1 implements like the 9GL series. We are seeing a significant move away from separate mowing and raking passes toward a single-operator “One-Pass” philosophy.

This trend is not only about saving time but also about maximizing the “harvest window.” In humid climates like the Korean summer, reducing the field drying time by even 24 hours can be the difference between Grade-A forage and moldy silage. Furthermore, as “Smart Farming” initiatives grow in South Korea, there is an increasing reliance on implements that offer uniform windrows, which are essential for automated baling systems and high-capacity forage harvesters.

4. Working Principle:

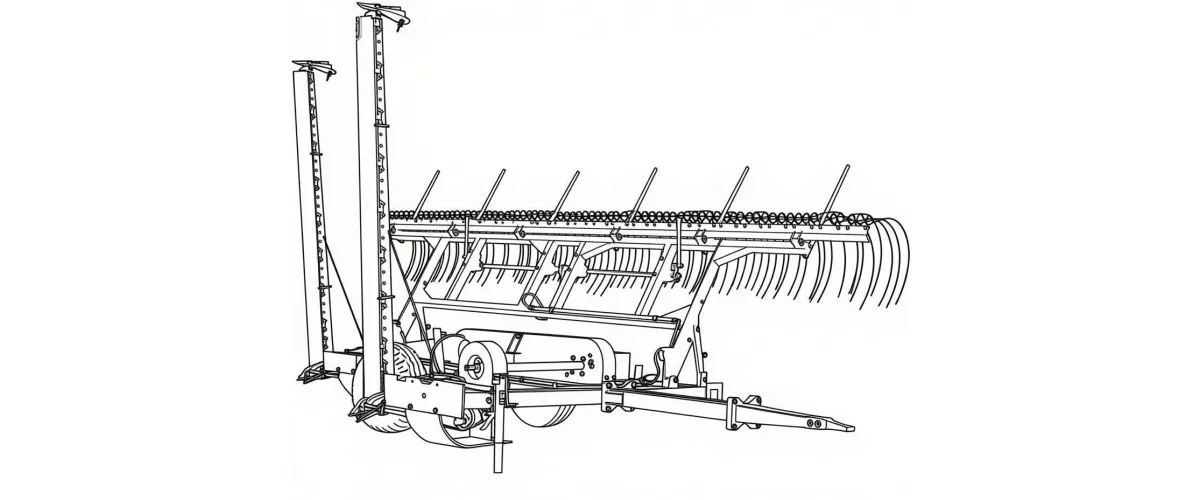

The 9GL-5.0/5.6 Towed Reciprocating Mower combines mowing and raking in one machine, which greatly enhances operational efficiency. The machine is designed to be towed by a tractor and uses reciprocating mower technology. This mechanism works by converting the tractor’s PTO (Power Take-Off) rotational power into linear motion through a precision crank-rod system. The two independent cutter bars (each 2.5 meters wide) are driven simultaneously, providing a combined cutting width of 5.0 meters to 5.6 meters.

Precision cutting: The reciprocating system offers a clean, shearing cut, which is more efficient than rotary systems, preserving the vascular structure of the grass and promoting faster regrowth.

No need for raking: By combining both mowing and raking functions, the mower collects and gathers the cut forage into windrows simultaneously, eliminating the need for a separate raking operation.

Fuel efficiency: This integration of mowing and raking reduces fuel consumption by up to 35%, making it more energy-efficient compared to using separate machines.

Soil preservation: The design minimizes soil compaction, which is crucial for sustainable farming, especially in regions like Gangwon-do and Jeju Island where the terrain can be uneven.

Wide compatibility: The mower is compatible with tractors in the 45–80 HP range, ensuring flexibility across various farming operations. The hydraulic folding chassis allows the machine to have a compact transport profile, which complies with road transport regulations in South Korea.

5. Global Success

Client 2 Profile: Agricultural Contractor, Jeju Island, South Korea

Client Testimonial:

“The heat-treated manganese steel blades are durable and wear-resistant, even when encountering rocks. The hydraulic folding system ensures we can safely transport the equipment between fields without worrying about width restrictions. The 5.0-meter cutting width allows us to efficiently handle large areas. All in all, it’s a high-quality product, and I will continue to use it in my contracting business.”

Client 3 Profile: Agricultural Cooperative, Pyeongchang, South Korea

Client Testimonial:

“The 9GL-5.6 mower has been a game-changer for our cooperative. We’ve switched from traditional separate mowing and raking equipment to this integrated solution, and we’ve noticed a huge improvement in operational efficiency. The machine is easy to operate, allowing us to harvest natural grass or cultivated pastures on small slopes without worrying about soil compaction. The cutting quality is excellent, and the machine’s productivity fully meets expectations. We’ve reduced fuel consumption and can now complete harvesting in half the time.”

Client 4 Profile: Dairy Farm Manager, Gangwon Province, South Korea

Client Testimonial:

“As a dairy farm manager, I need to ensure we provide the highest quality feed for our cows. The 9GL-5.0 mower helps us achieve this goal. The productivity range of 2.4-2.8 hectares/hour is perfect for our farm’s needs. With its efficient cutting and minimal impact on the soil, this mower is ideal for our terrain. The clean cut provided by the reciprocating cutting technology helps maintain the nutritional value of the feed, and we’ve noticed our hay dries more evenly, which significantly improves the quality of our silage. This is a must-have for any serious dairy farmer.”

6. EVER-POWER Factory: Customization & Quality Assurance

我们的生产基地位于呼伦贝尔经济技术开发区,占地面积超过 32,000平方米 公司配备了最先进的数控激光切割机、自动焊接生产线和静电粉末喷涂生产线。我们不仅仅是组装商,更是一家拥有深厚研发能力的综合性制造商。

定制服务(OEM/ODM): 我们了解不同地区的农业条件存在差异。针对韩国市场,我们提供以下定制选项:

• 水力适应: 调整阀门压力以匹配特定的 LS 或大同拖拉机液压流量。

• 轮胎升级: 可选配更宽的浮力轮胎,适用于深泥稻田。

• 颜色与品牌: 为经销商和分销商提供OEM品牌推广服务。

我们持有 ISO9001质量管理体系认证 公司已被认定为国家高新技术企业。每台9YG-2.24D打包机在出厂前都要经过严格的48小时连续运行测试,以确保到货时零缺陷。

7. Related products

7.1 Gearbox:

兼容型号:EP-FK263(方捆打捆机)、EP-RC30 系列(圆捆打捆机,传动比 1:2,兼容 35mm 6 齿花键轴)。应用:将动力输出轴 (PTO) 动力传递至打捆机构,适用于 New Holland 630 或 John Deere 535。参数:扭矩 > 500 Nm,20% 节油。选择这款变速箱的理由:尺寸可定制(可缩小至 250-300 毫米),耐粘性污染物(橡胶烟雾),IP65 防护等级。动力输出轴:兼容型号:EP-PTO 系列(1-3/8″ Z6 花键,可调长度 600-1200mm)。应用:连接拖拉机和打捆机主驱动装置,适用于9YG-1.0C型。扭矩传递效率>95%,兼容SAE/EURO法兰。适用理由:防水设计,适用于湿式青贮作业;可替代 Weasler 系列。

7.2 链条 链轮:

兼容型号:ANSI 链条,带EP链轮(节距12.7-19.05mm,滚轮直径10-12mm)。应用范围:用于输送带或捆扎机构,适用于方捆/圆捆打捆机秸秆输送。宽度25-40毫米,耐磨钢材质。适用理由:与 Kobelco 或 HF 集团设备兼容,降低链条断裂风险;可提供食品级青贮饲料选项。

7.3 Couplings:

兼容型号:EP-Coupling 200 系列(扭矩匹配 500-1000 Nm)。应用:连接齿轮箱和打包辊,抑制振动。适用理由:高循环耐用性,兼容 Bondioli 和 Pavesi。

7.4 液压缸:

液压缸: EP-HC系列(缸径50-100mm,行程300-600mm),适用于捆包提升。轴承和密封件:6208-2RS 轴承,L10 寿命 >10000 小时,防尘密封。兼容性表格:与 Comer 250T 完全互换(扭矩匹配,价格仅为 35%);法兰与北美 4 螺栓 PTO 模式匹配。* 免责声明:以上提及的其他品牌名称仅供参考。我们不提供带有这些品牌名称的原装产品或设备。* 参数会因工作条件而异,请参考实际图纸。建议选型前确认接口尺寸。

8. Forage Harvesting Professional FAQ

Q1. What is the current commercial forage harvester price for the 5.6m trailed mower/rake delivered to Busan?

A1. The final investment for a 9GL-5.6 depends on your specific shipping logistics and customization needs. For commercial cooperatives in South Korea, we provide competitive high-capacity agricultural mower quotes that include international duties. Please click our “Get a Quote” button for a detailed commercial proposal within 24 hours.

Q2. Where can I find a reliable Trailed Mower/Rake supplier Korea that offers local maintenance support?

A2. We are a specialized industrial manufacturer with a dedicated export department serving the Korean agricultural sector. We partner with local technical service centers in Gyeonggi and Gangwon provinces to ensure your 9GL series receives genuine manganese steel spare parts and seasonal calibration.

Q3. How does the reciprocating mower technology benefit hay quality in humid Jeju Island pastures?

A3. Unlike rotary mowers that “beat” the grass, our reciprocating system uses a clean shearing cut. This preserves the plant’s moisture-conducting vessels, which allows the forage to dry more uniformly. In humid Jeju climates, this prevents internal fermentation and significantly improves the Grade-A haylage recovery rate.

Q4. What is the recommended tractor horsepower for pulling a 5.0m wide 9GL series mower/rake on hills?

A4. For optimal performance on sloped terrains typical of the Korean highlands, we recommend a tractor with at least 65 to 80 HP (48-58 kW). This ensures sufficient PTO torque to drive the 5.0m reciprocating cutter bar while maintaining steady towing stability at ground speeds of 5-8 km/h.

Q5. Are there specific Korea pasture harvesting regulations regarding the folding width of large agricultural implements?

A5. Yes, Korean regulations strictly limit the width of machinery on public agricultural roads. The 9GL-5.0/5.6 is designed with a high-clearance hydraulic folding system that brings its 5.6m working width down to a legal transport profile, allowing you to move between disconnected plots without special escort permits.

Q6. Which manganese steel alloy is used in your blades to resist stony volcanic soils in Jeju-do?

A6. We utilize a proprietary 65Mn heat-treated manganese alloy for all our reciprocating blades. This material is specifically chosen for its balanced hardness and fracture toughness, ensuring that even if the blade strikes a Jeju volcanic stone, it resists shattering and maintains a clean cutting edge.

Q7. How often should I inspect the reciprocating crank-rod system to maintain peak productivity?

A7. We recommend a daily visual inspection of the lubrication points during the harvest season. For every 100 operational hours, a thorough check of the drive belt tension and crank pin alignment is advised. This simple maintenance ensures the machine maintains its 4.5 hm²/h productivity rating for years.

Q8. Why should I choose an integrated mower-rake over two separate tractor-mounted implements?

A8. Choosing an integrated 9GL unit reduces your “Fuel-per-Hectare” cost by roughly 30%. More importantly, it halves the amount of heavy equipment passes on your pasture, which dramatically reduces soil compaction and promotes deeper root growth—a vital part of sustainable forage management equipment strategies.

Q9. Can your factory provide a high-capacity agricultural mower quote for custom tractor hitch standards used in Korea?

A9. Absolutely. While the 9GL series comes with a standard category 2 trailed hitch, we can customize the connection points to match specific LS Mtron or TYM tractor drawbar standards. We specialize in providing bespoke solutions that ensure a “Plug-and-Play” experience for your existing tractor fleet.

Q10. How does the 9GL-5.6 trailed mower/rake comply with South Korean land management construction laws?

A10. Under Korean MAFRA guidelines, agricultural machinery must minimize negative soil impact. Our 9GL series complies by utilizing high-flotation tires that spread the machine’s 1050 kg weight evenly. This prevents topsoil displacement and subsoil compaction, which is mandatory for maintaining soil fertility in permanent pasture zones.

编辑:PXY

*免责声明:以上提及的其他品牌名称仅供参考。我们不提供带有这些品牌名称的原装产品或设备。