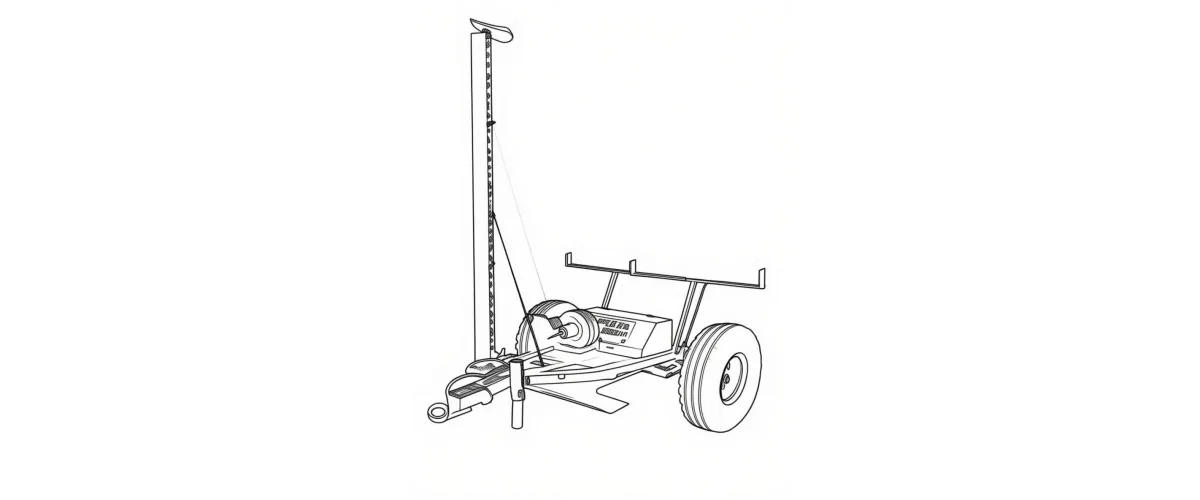

描述

1. 9GD-2.5 Technical Specifications

| 不。 | 物品 | 单元 | 规格 |

|---|---|---|---|

| 1 | 型号名称 | / | 9GD-2.5 Trailed Single-Blade Mower |

| 2 | 挂钩类型 | / | 拖曳 |

| 3 | 切割器结构类型 | / | 互惠 |

| 4 | 切割宽度 | 米 | 2.5 |

| 5 | 匹配功率范围 | kW | 15-35 |

| 6 | 工作速度范围 | 公里/小时 | 6~10 |

| 7 | 活动叶片数量 | 件 | 34 |

| 8 | Dimensions (L × W × H) | 毫米 | 2000×4300×950 |

| 9 | 功率输出轴转速 | 转/分钟 | 540 |

| 10 | 平均切割高度 | 毫米 | 50-70 |

| 11 | 生产率 | 平方米/小时 | 2.0-3.0 |

| 12 | 操作员数量 | (人) | 1 |

| 13 | 结构重量 | 公斤 | 490 |

2. Engineering Excellence: Principles and Scenarios

The working principle of the 9GD-2.5 relies on the mechanical conversion of rotational energy into high-speed linear reciprocating motion. The tractor’s PTO shaft transmits power to a primary drive pulley, which then activates the offset crank mechanism. This drives the cutter bar’s knives across stationary guards, creating a shearing effect similar to industrial scissors. This method is preferred in pasture management equipment in Korea because it minimizes soil disturbance and prevents the “shattering” of delicate forage leaves, preserving the nutritional content of the hay.

In terms of materials, the main frame is constructed from high-grade structural carbon steel, while the cutter bar features heat-treated manganese steel blades for exceptional wear resistance and impact durability against hidden field debris. This machine is optimized for various scenarios, including the management of natural mountain pastures, the harvesting of high-density planted forage, and even large-scale landscape maintenance in construction-reclaimed lands. Its towed configuration offers superior tracking and stability on uneven terrains compared to side-mounted alternatives, ensuring consistent cutting height across the entire 2.5-meter swath.

3. Universal Compatibility Matrix

| Tractor Brand | 兼容性状态 | PTO Requirement |

|---|---|---|

| LS Mtron / TYM / Daedong | High (Standard 3-Point Hitch) | 540 RPM |

| Kubota / Yanmar | High (Category I & II) | 540 / 720 RPM |

| John Deere / New Holland | Full Integration Ready | Standard 6-Spline |

4. Regulatory Compliance & Land Management Laws

5. Market Trend Analysis: The Future of Forage Harvesting

6. EVER-POWER Factory: Customization & Quality Assurance

我们的生产基地位于呼伦贝尔经济技术开发区,占地面积超过 32,000平方米 公司配备了最先进的数控激光切割机、自动焊接生产线和静电粉末喷涂生产线。我们不仅仅是组装商,更是一家拥有深厚研发能力的综合性制造商。

定制服务(OEM/ODM): 我们了解不同地区的农业条件存在差异。针对韩国市场,我们提供以下定制选项:

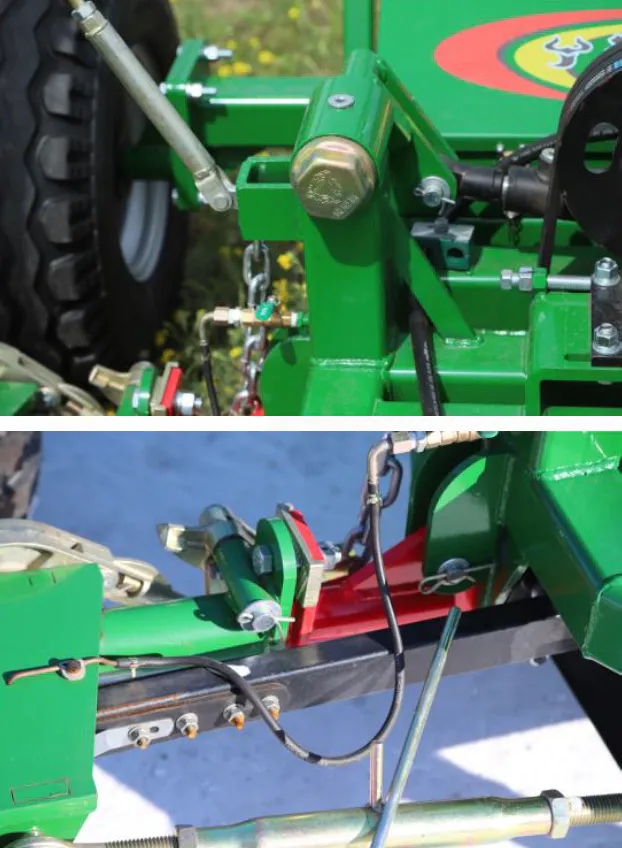

• 水力适应: 调整阀门压力以匹配特定的 LS 或大同拖拉机液压流量。

• 轮胎升级: 可选配更宽的浮力轮胎,适用于深泥稻田。

• 颜色与品牌: 为经销商和分销商提供OEM品牌推广服务。

我们持有 ISO9001质量管理体系认证 公司已被认定为国家高新技术企业。每台9YG-2.24D打包机在出厂前都要经过严格的48小时连续运行测试,以确保到货时零缺陷。

7. Related products

7.1 Gearbox:

兼容型号:EP-FK263(方捆打捆机)、EP-RC30 系列(圆捆打捆机,传动比 1:2,兼容 35mm 6 齿花键轴)。应用:将动力输出轴 (PTO) 动力传递至打捆机构,适用于 New Holland 630 或 John Deere 535。参数:扭矩 > 500 Nm,20% 节油。选择这款变速箱的理由:尺寸可定制(可缩小至 250-300 毫米),耐粘性污染物(橡胶烟雾),IP65 防护等级。动力输出轴:兼容型号:EP-PTO 系列(1-3/8″ Z6 花键,可调长度 600-1200mm)。应用:连接拖拉机和打捆机主驱动装置,适用于9YG-1.0C型。扭矩传递效率>95%,兼容SAE/EURO法兰。适用理由:防水设计,适用于湿式青贮作业;可替代 Weasler 系列。

7.2 链条 链轮:

兼容型号:ANSI 链条,带EP链轮(节距12.7-19.05mm,滚轮直径10-12mm)。应用范围:用于输送带或捆扎机构,适用于方捆/圆捆打捆机秸秆输送。宽度25-40毫米,耐磨钢材质。适用理由:与 Kobelco 或 HF 集团设备兼容,降低链条断裂风险;可提供食品级青贮饲料选项。

7.3 Couplings:

兼容型号:EP-Coupling 200 系列(扭矩匹配 500-1000 Nm)。应用:连接齿轮箱和打包辊,抑制振动。适用理由:高循环耐用性,兼容 Bondioli 和 Pavesi。

7.4 液压缸:

液压缸: EP-HC系列(缸径50-100mm,行程300-600mm),适用于捆包提升。轴承和密封件:6208-2RS 轴承,L10 寿命 >10000 小时,防尘密封。兼容性表格:与 Comer 250T 完全互换(扭矩匹配,价格仅为 35%);法兰与北美 4 螺栓 PTO 模式匹配。* 免责声明:以上提及的其他品牌名称仅供参考。我们不提供带有这些品牌名称的原装产品或设备。* 参数会因工作条件而异,请参考实际图纸。建议选型前确认接口尺寸。

8. Frequently Asked Questions (FAQ)

Q1: How much does the 9GD-2.5 Towed Single-Blade Lawn Mower cost for delivery to Busan port?

A1: The **Reciprocating cutter bar mower price** for the 9GD-2.5 varies based on order volume and customization. Generally, for a single unit, the price is highly competitive for the Korean market. To get an exact quote including shipping and insurance to Busan or Incheon, please click our ‘Get a Quote’ button to speak with a sales representative.

Q2: Where can I find a reliable Towed Single-Blade Lawn Mower manufacturer that ships directly to South Korea?

A2: Jiujia Machinery is a direct-to-market manufacturer with extensive experience exporting to the South Korean agricultural sector. We handle all international logistics and provide direct factory support for the 9GD series, ensuring you avoid middleman markups while receiving genuine industrial-grade equipment.

Q3: What is the recommended tractor horsepower for operating the 9GD-2.5 lawn mower on sloped pastures?

A3: For the 9GD-2.5 model, the optimal power requirement is between 25 and 40 HP (18.4-30 kW)[cite: 1]. If you are operating in sloped regions like the Gangwon highlands, we recommend using a tractor at the higher end of that range (35-40 HP) to ensure consistent PTO speed and towing stability.

Q4: Which reciprocating blade material is best for high-moisture sudangrass harvesting in Korea?

A4: We utilize heat-treated manganese steel for all 9GD-2.5 cutter bars. This material is specifically chosen for its ability to maintain a sharp edge even when cutting high-moisture forage, preventing the “clogging” that often occurs with standard carbon steel blades in humid Korean summers.

Q5: How do I choose between the 9GD-2.5 and the upgraded version for my farm’s specific needs?

A5: The standard 9GD-2.5 is designed for maximum cost-efficiency and reliability using a traditional crank-rod system. [cite_start]If your priority is a proven, high-productivity workhorse (up to 2.0 hm²/h) [cite: 1] with simpler maintenance requirements, the standard 9GD-2.5 is the ideal choice for most commercial forage farms.

Q6: What are the maintenance requirements for the crank mechanism in the 9GD-2.5 lawn mower?

A6: To ensure longevity, the primary maintenance task is daily lubrication of the crank pin and connecting rod bearings. We also recommend checking the tension of the drive belt every 20 operational hours. [cite_start]These simple steps prevent mechanical wear and ensure your machine maintains its 5-8 km/h working speed[cite: 1].

Q7: Does Jiujia offer product customization for different tractor hitch standards used in Korea?

A7: Yes! While the 9GD-2.5 comes with a standard towed hitch, we can customize the connection points to match specific LS Mtron or Daedong tractor standards. We can also adjust the PTO spline configuration to ensure a seamless “plug-and-play” experience for your existing fleet.

Q8: When is the best time to replace the cutter bar guards on the 9GD-2.5?

A8: Guards should be inspected every season. If you notice a “tearing” rather than a “cutting” of the grass, or if the stationary edges have become rounded, it is time for a replacement. [cite_start]Maintaining sharp guards ensures you stay within the 30-80 mm cutting height range effectively[cite: 1].

Q9: What safety certifications does the 9GD-2.5 hold for international agricultural equipment markets?

A9: Our equipment is manufactured under ISO 9001 quality management systems and meets the essential safety requirements for international agricultural trade. We provide full technical documentation to assist with South Korean MAFRA safety audits and insurance requirements.

Q10: Why should I choose a towed single-blade mower over a standard rotary mower for livestock feed?

A10: Towed single-blade mowers use a reciprocating cut that preserves the stem’s vascular structure. This results in significantly higher forage quality and faster field drying times compared to rotary mowers, which can “beat” the grass and cause sap loss, especially in high-sugar crops like alfalfa.

编辑:PXY

*免责声明:以上提及的其他品牌名称仅供参考。我们不提供带有这些品牌名称的原装产品或设备。