Опис

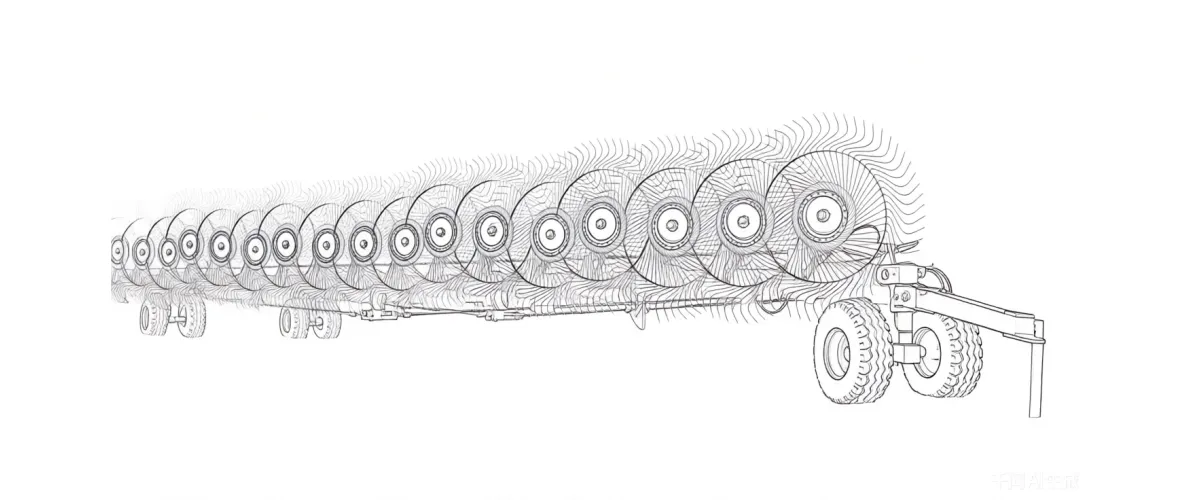

1. Technical Specifications: 9LZD-9.0 Series

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9LZD-9.0 Finger Wheel Hay Rake |

| 2 | Structural Type | / | Finger Wheel Type |

| 3 | Hitch Type | / | Trailed |

| 4 | Model Specification | / | 9LZD-9.0 |

| 5 | Required Power | kW | 55–75 |

| 6 | Overall Dimensions (L × W × H) | m | 16.8 × 3.9 × 1.6 (Working Condition) |

| 7 | Machine Weight | kg | 1240 |

| 8 | Working Width | m | 9 |

| 9 | Operating Speed | km/h | 8–10 |

| 10 | Transport Speed | km/h | 12 |

| 11 | Number of Finger Wheels | pcs | 17 |

| 12 | Number of Spring Teeth | pcs | 1020 (17 wheels × 60 teeth per wheel) |

| 13 | Operators Required | person | 1 |

| 14 | Windrow Width | m | 0.8–1.2 |

| 15 | Raking Loss Rate | ≤ | 2% |

| 16 | Productivity | hm²/h | 7.2–9 |

2. Key Facts & Performance Metrics

- Ultra-Wide Coverage: 9.0m operating width driven by 17 dynamic finger discs (1020 total tines).

- High Productivity: Achieves work rates of 7.2 to 9 hm²/h, significantly outperforming standard rotary rakes.

- Ground-Driven Efficiency: Requires no PTO input; the finger wheels are driven by ground contact, saving tractor fuel.

- Hydraulic Precision: Full hydraulic lifting and folding system ensures seamless transition between transport and working modes.

- Terrain Adaptability: Floating finger wheel design follows ground contours, ideal for the rolling hills of Jeolla and Gyeongsang provinces.

3. The Ultimate Forage Solution: 9LZD-9.0 Disc-type Hay Rake

4. Engineering Mechanics: Working Principles and Material Science

5. Regulatory Compliance: Safety and Land Management Standards

6. Market Analysis: The Demand for High-Capacity Solutions

The agricultural machinery landscape in South Korea and globally is shifting decisively towards efficiency and scale. With the rural workforce aging and labor costs rising, farmers are moving away from smaller, labor-intensive implements. The disc-type hay rake search trends indicate a preference for units like the 9LZD-9.0 that can replace the work of two or three smaller rakes. While 8-10 wheel rakes were once standard, the 17-wheel configuration is becoming the new benchmark for professional contractors and large cooperatives.

This trend is driven by the need to match the speed of modern high-density balers and forage harvesters. Additionally, there is a growing awareness of “feed hygiene.” Farmers are increasingly rejecting “parallel bar hay rake” models that can drag soil into the windrow, favoring the cleaner lift of finger wheel rakes. The marketis expanding, with a projected 15% annual growth in the 9-meter+ segment over the next five years in the Asian Pacific region.

7. Tractor & Implement Compatibility

| Component | Compatibility Details |

|---|---|

| Tractor Brand (Korea) | LS Mtron (XP/MT Series), TYM (T1003/T1103), Daedong (Kioti HX Series) with 75-102 HP. |

| Hydraulic System | Requires 1 Rear Remote Valve (Double Acting) for lift/fold control. Standard ISO hydraulic couplers. |

| Hitch Type | Standard Agricultural Drawbar / Clevis Hitch. Adaptable to Category II/III dimensions. |

| Terrain Suitability | Flat pasture, rice paddies (post-harvest), gentle slopes. Not recommended for forestry or deep mud. |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

8. Customer Success Story:

9. EVER-POWER Raker Manufacturer: Customization & Quality Assurance

Located in the Hulunbuir Economic and Technological Development Zone, our manufacturing facility spans over 32,000 square meters and is equipped with state-of-the-art CNC laser cutting machines, automatic welding lines, and electrostatic powder coating lines. We are not just an assembler; we are a comprehensive manufacturer with deep R&D capabilities.

Customization Services (OEM/ODM): We understand that agricultural conditions vary by region. For the South Korean market, we offer customization options including:

• Hydraulic Adaptation: Adjusting valve pressures to match specific LS or Daedong tractor hydraulic flows.

• Tire Upgrades: Optional wider flotation tires for deep-mud paddy fields.

• Color & Branding: OEM branding services for dealers and distributors.

We hold ISO9001 Quality Management System Certification and have been recognized as a National High-Tech Enterprise. Every 9YG-2.24D baler undergoes a rigorous 48-hour continuous operation test before shipment to ensure zero defects upon arrival.

10. Related products

10.1 Gearbox:

Compatible models: EP-FK263 (square baler), EP-RC30 series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.Why it’s suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.

10.2 Chains & Sprockets:

Compatible Models: ANSI chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.Why it’s suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.

10.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.Why it’s suitable: High-cycle durability, compatible with Bondioli & Pavesi.

10.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.* Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.* Parameters vary depending on working conditions; please refer to the actual drawings. It is recommended to confirm interface dimensions before selection.

11. Frequently Asked Questions (FAQ)

Q1. What is the estimated price for the 9LZD-9.0 disc-type hay rake for sale delivered to Incheon?

A1. Pricing depends on raw material costs and current shipping rates. For a precise CIF Incheon quote including customs documentation, please use the “Get a Quote” button to contact our sales team.

Q2. How wide is this 17-wheel hay rake compared to a standard 10-wheel hay rake?

A2. A standard 10-wheel rake covers about 6-7 meters. The 9LZD-9.0 with 17 wheels offers a massive 9-meter working width, increasing coverage by nearly 40% per pass.

Q3. Where can I find disc-type hay rake parts, like replacement tines in South Korea?

A3. We provide a spare parts kit with every machine purchase. Additionally, our 65Mn tines use standard international mounting specs, making them compatible with many local aftermarket suppliers or direct orders from us.

Q4. Is the 9LZD-9.0 considered a high-capacity hay rake suitable for contractors?

A4. Absolutely. With a 9m width and productivity of up to 9 hectares per hour, it is specifically designed for high-capacity commercial operations and agricultural contractors.

Q5. Can this rake be used as a used hay rake for sale near me, or do you only sell new?

A5. EVER-POWER manufactures and sells only brand-new equipment. However, our durable build quality means these units hold their value well if you ever decide to sell it as a used unit later.

Q6. How does this compare to a parallel bar hay rake for handling alfalfa?

A6. While parallel bar rakes are gentle, they are much slower and narrower. The 9LZD-9.0 offers a good balance of gentle handling via ground-drive wheels while providing significantly higher speed and capacity.

Q7. What hydraulic connections does my tractor need for this disc-type hay rake?

A7. You will need one set of rear remote hydraulic valves (two ports, double-acting) to operate the hydraulic cylinder that lifts and folds the rake arms for transport.

Q8. Can I see disc-type hay rake reviews from other customers before purchasing?

A8. Yes, we can provide testimonials and case studies from our international clients. Please contact our sales team, and we will share relevant feedback from users in similar agricultural climates.

Q9. How long to wait before raking hay using the 9LZD-9.0 model?

A10. It depends on moisture, but typically you rake when moisture is around 40-50% to prevent leaf shatter. The 9LZD-9.0 can also be used for turning damp hay (tedding) to accelerate this drying process.

Editor: PXY