Опис

1. Technical Specifications: 9GL-2.5/2.9 Series

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9GL-2.5 / 2.9 Towed Mower-Rake |

| 2 | Hitch Type | / | Towed |

| 3 | Cutter Structure Type | / | Reciprocating |

| 4 | Cutting Width | m | 2.5 |

| 6 | Raking Working Width | m | 2.9 |

| 7 | Working Speed Range | km/h | 6–7 |

| 8 | Productivity | hm²/h | Mowing: 1.2–1.44 / Raking: 1.5–1.8 |

| 9 | Average Cutting Height | mm | 60–70 |

| 10 | Matching Power | kW | 25–55 |

| 11 | Tractor PTO Speed | r/min | 540 |

| 12 | Machine Weight | kg | 920 |

| 13 | Number of Rake Teeth | pcs | 42 |

| 14 | Rake Tooth Spacing | mm | 71 |

| 15 | Overall Dimensions (L × W × H) | mm | — |

| 16 | Transport Condition Dimensions | mm | 3100 × 2920 × 2900 |

| 17 | Working Condition Dimensions | mm | 3100 × 5000 × 950 |

| 18 | Number of Moving Blades | pcs | 34 |

2. Key Facts & Capabilities

- Dual-Action Efficiency: Cuts and rakes forage in one operation, achieving productivity rates up to 1.8 hm²/h.

- Power Requirement: Optimized for mid-range tractors (25-55 kW), making it ideal for the “pull behind rake for tractor” category.

- Terrain Adaptability: Specifically designed for flat grasslands and gentle slopes, perfect for Jeolla and Chungcheong plains.

- Precision Engineering: Features a sensitive hydraulic lifting mechanism for obstacle avoidance and transport safety.

- Cost-Effective: Reduces labor hours and equipment wear by halving the required field passes.

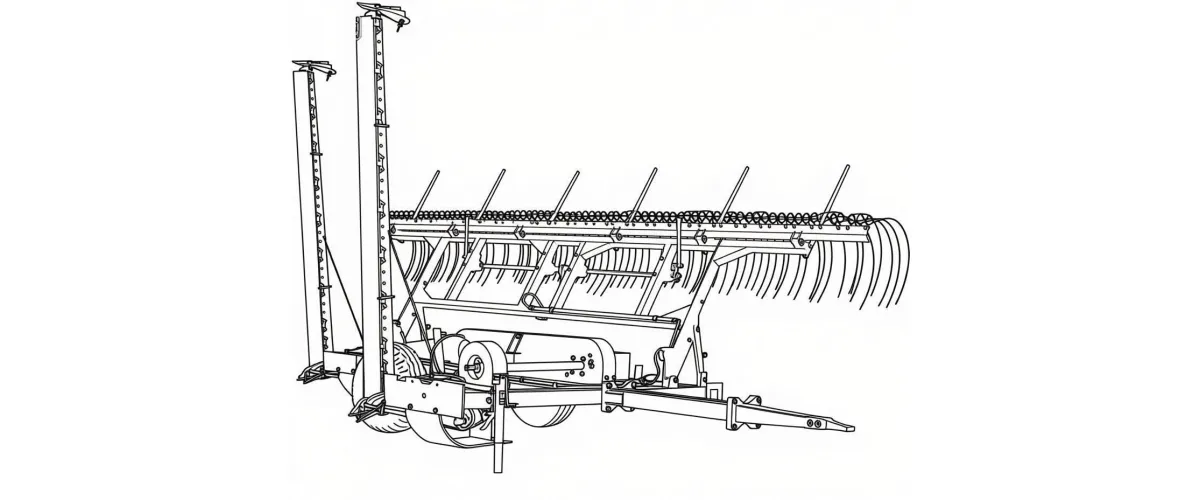

3. Revolutionizing Harvest with the 9GL-2.5/2.9 Trailed Mower Rake

4. Engineering Excellence: Working Principles and Material Metallurgy

The operational success of the 9GL-2.5/2.9 model lies in its sophisticated synchronization of cutting and raking mechanisms driven by the tractor’s PTO shaft (540 r/min) and rear hydraulic output. The unit features a specialized offset traction frame that allows the mower to operate to the side of the tractor, preventing the tires from trampling the standing crop before it is cut—a common issue with inferior setups.

The cutter bar utilizes high-carbon alloy steel knife guards and serrated sections that undergo rigorous heat treatment to achieve a hardness of HRC 50-55, ensuring prolonged edge retention even in abrasive, sandy soil conditions often found in coastal farming regions. Following the cutter, the raking mechanism employs a series of curved spring-steel tines. These are not standard wire; they are crafted from 65Mn spring steel, known for its high fatigue strength and elasticity. As the crop is severed, the rake immediately gathers the material into fluffy, aerated windrows. This immediate windrowing is crucial for creating airflow, allowing the hay to cure evenly. The chassis is constructed from Q345B structural steel, providing the “heavy-duty trailed mower rake” characteristics necessary to endure vibration and terrain undulations without structural fatigue.

5. Global Compliance: Agricultural Machinery and Land Management Regulations

7. Market Trends: The Shift Towards Integrated Harvesting

The global agricultural machinery market is witnessing a decisive shift towards multi-functional implements, driven by rising fuel costs and labor shortages. In South Korea, where the rural population is aging and labor is scarce, the demand for “used trailed mower rake” and new integrated solutions has spiked by 15% year-over-year. Farmers are moving away from single-purpose machines towards units like the 9GL series that perform multiple tasks simultaneously.

This trend is not isolated; in the US and Europe, “pull behind rake for riding mower” and larger tractor-mounted combination units are dominating the market segment for small-to-medium acreage farms. The trend also favors “smart farming” compatibility—while the 9GL is a mechanical unit, its compatibility with modern GPS-guided tractors allows for precision windrowing, reducing waste. Furthermore, the push for organic dairy farming requires gentler handling of forage to preserve nutritional value, a requirement that rotary mowers struggle to meet but reciprocating mowers excel at. Investing in a 9GL-2.5/2.9 is investing in the future trajectory of efficient, sustainable agriculture.

8. Tractor & Component Compatibility

| Category | Details / Brand Compatibility |

|---|---|

| Tractor Brands (South Korea) | Fully compatible with LS Mtron, TYM, Daedong (Kioti), and Kukje Machinery tractors in the 35-75 HP range. |

| Tractor Brands (Global) | Compatible with John Deere (5E Series), Kubota (M Series), Massey Ferguson, and New Holland. |

| PTO Connection | Standard 1-3/8″ 6-Spline, 540 RPM. Adapters available for non-standard shafts. |

| Hydraulic Requirement | Requires 1 Rear Remote Valve (Double Acting recommended for lift control). |

| Replacement Parts | Knife sections compatible with generic sickle bar standards (Ford/New Holland style). Rake teeth compatible with universal 65Mn spring tine mounts. |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

9. Customer Success Story:

10. EVER-POWER Mower rake Manufacturer: Customization & Quality Assurance

Located in the Hulunbuir Economic and Technological Development Zone, our manufacturing facility spans over 32,000 square meters and is equipped with state-of-the-art CNC laser cutting machines, automatic welding lines, and electrostatic powder coating lines. We are not just an assembler; we are a comprehensive manufacturer with deep R&D capabilities.

Customization Services (OEM/ODM): We understand that agricultural conditions vary by region. For the South Korean market, we offer customization options including:

• Hydraulic Adaptation: Adjusting valve pressures to match specific LS or Daedong tractor hydraulic flows.

• Tire Upgrades: Optional wider flotation tires for deep-mud paddy fields.

• Color & Branding: OEM branding services for dealers and distributors.

We hold ISO9001 Quality Management System Certification and have been recognized as a National High-Tech Enterprise. Every 9YG-2.24D baler undergoes a rigorous 48-hour continuous operation test before shipment to ensure zero defects upon arrival.

11. Related products

11.1 Gearbox:

Compatible models: EP-FK263 (square baler), EP-RC30 series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.Why it’s suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.

11.2 Chains & Sprockets:

Compatible Models: ANSI chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.Why it’s suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.

11.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.Why it’s suitable: High-cycle durability, compatible with Bondioli & Pavesi.

11.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.* Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.* Parameters vary depending on working conditions; please refer to the actual drawings. It is recommended to confirm interface dimensions before selection.

12. Frequently Asked Questions (FAQ)

Q1. What is the estimated price for the 9GL-2.5 mower rake, including shipping to Incheon, South Korea?

A1. The FOB price fluctuates based on raw material costs, but we offer factory-direct pricing. For a precise CIF Incheon quote including customs clearance documentation, please contact our sales team via the “Get a Quote” button.

Q2. Which tractor horsepower is strictly required to operate the 9GL-2.9 heavy-duty trailed mower rake efficiently?

A2. To operate the 9GL-2.9 efficiently without straining your engine, we recommend a tractor with at least 35HP, though 50-55HP is ideal for handling hilly terrain and maintaining consistent PTO speed.

Q3. How does this reciprocating mower rake compare to a disc mower in terms of crop quality and leaf retention?

A3. Unlike disc mowers that shatter leaves due to high impact speed, our reciprocating sickle bar creates a scissor-like cut, preserving leaf integrity, which is crucial for high-protein feed like alfalfa.

Q4. Where can I buy replacement teeth or knife sections for this trailed mower rake if I am in Australia?

A4. We supply a comprehensive spare parts kit with every unit. Additionally, our components use standard international sizing, so you can find compatible knife sections at local agricultural supply stores or order directly from us via express air freight.

Q5. Can this machine function as a pull-behind rake for a tractor on uneven or rocky terrain safely?

A5. While it handles gentle slopes well, reciprocating cutters are sensitive to large rocks. However, our hydraulic lift system allows the operator to quickly raise the cutter bar over obstacles, preventing damage.

Q6. What is the Minimum Order Quantity (MOQ) for a customized OEM order of these mower rakes?

A6. For standard units, our MOQ is 1 set. For OEM customization (custom color, branding, or chassis modification), the MOQ is typically 5 sets to optimize production costs.

Q7. When is the best time to order to ensure delivery before the harvest season in the Northern Hemisphere?

A7. Due to high demand, we recommend placing orders 2-3 months before your harvest season begins. For Spring harvest, ordering in late Winter ensures your equipment arrives and is assembled in time.

Q8. How do I connect the hydraulic system if my tractor only has one rear hydraulic output valve?

A8. The 9GL series typically requires one set of hydraulic outlets for the lift cylinder. If your tractor lacks outlets, we can provide a manual mechanical lift conversion or a diverter valve kit as an option.

Q9. Is there a warranty for the gearbox and structural components of the 9GL-2.5 trailed mower?

A9. Yes, EVER-POWER provides a 12-month warranty on the main structural frame and the gearbox. Wear parts like knife sections and rake tines are excluded but are supplied as spares.

Q10. Do you provide installation manuals or video guides for assembling the machine upon arrival?

A10. Absolutely. We provide a detailed PDF manual in English (and other languages upon request) and a step-by-step video installation guide to ensure you can assemble the trailed mower rake easily.

Editor: PXY