விளக்கம்

1. 9GD-2.5 Technical Specifications

| இல்லை. | பொருள் | அலகு | விவரக்குறிப்பு |

|---|---|---|---|

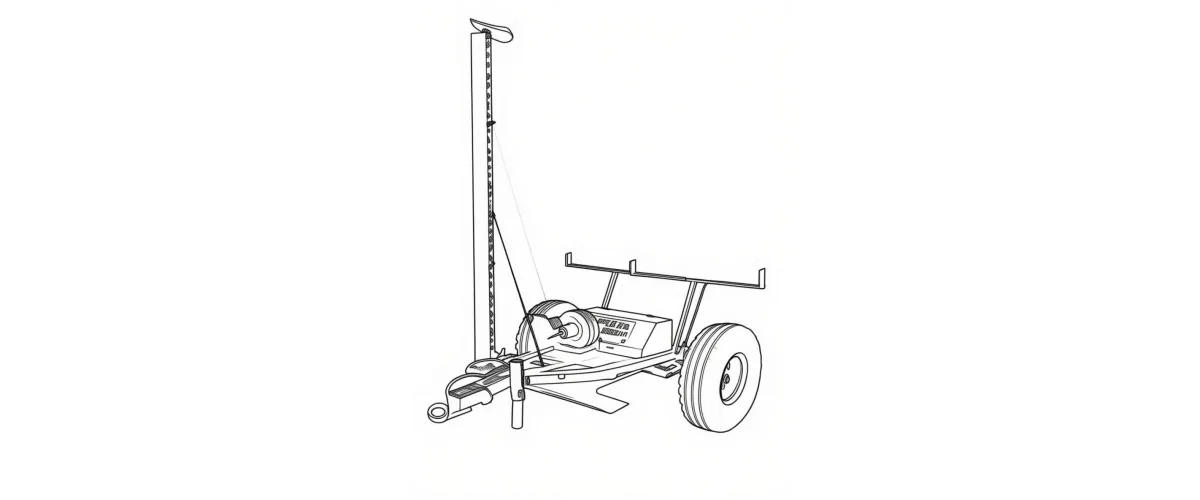

| 1 | Model Name | / | 9GD-2.5 Trailed Single-Blade Mower |

| 2 | ஹிட்ச் வகை | / | பின்தங்கிய |

| 3 | Cutter Structure Type | / | Reciprocating |

| 4 | வெட்டும் அகலம் | மீ | 2.5 |

| 5 | Matching Power Range | கிலோவாட் | 15-35 |

| 6 | வேலை வேக வரம்பு | கிமீ/ம.நே. | 6~10 |

| 7 | Number of Moving Blades | pcs | 34 |

| 8 | பரிமாணங்கள் (L × W × H) | மிமீ | 2000×4300×950 |

| 9 | பவர் அவுட்புட் ஷாஃப்ட் வேகம் | r/நிமிடம் | 540 |

| 10 | சராசரி வெட்டு உயரம் | மிமீ | 50-70 |

| 11 | தயாரிப்பு | hm2/h | 2.0-3.0 |

| 12 | ஆபரேட்டர்களின் எண்ணிக்கை | (நபர்கள்) | 1 |

| 13 | கட்டமைப்பு எடை | கிலோ | 490 |

2. Engineering Excellence: Principles and Scenarios

The working principle of the 9GD-2.5 relies on the mechanical conversion of rotational energy into high-speed linear reciprocating motion. The tractor’s PTO shaft transmits power to a primary drive pulley, which then activates the offset crank mechanism. This drives the cutter bar’s knives across stationary guards, creating a shearing effect similar to industrial scissors. This method is preferred in pasture management equipment in Korea because it minimizes soil disturbance and prevents the “shattering” of delicate forage leaves, preserving the nutritional content of the hay.

In terms of materials, the main frame is constructed from high-grade structural carbon steel, while the cutter bar features heat-treated manganese steel blades for exceptional wear resistance and impact durability against hidden field debris. This machine is optimized for various scenarios, including the management of natural mountain pastures, the harvesting of high-density planted forage, and even large-scale landscape maintenance in construction-reclaimed lands. Its towed configuration offers superior tracking and stability on uneven terrains compared to side-mounted alternatives, ensuring consistent cutting height across the entire 2.5-meter swath.

3. Universal Compatibility Matrix

| டிராக்டர் பிராண்ட் | Compatibility Status | PTO Requirement |

|---|---|---|

| LS Mtron / TYM / Daedong | High (Standard 3-Point Hitch) | 540 RPM |

| Kubota / Yanmar | High (Category I & II) | 540 / 720 ஆர்.பி.எம். |

| John Deere / New Holland | Full Integration Ready | நிலையான 6-ஸ்ப்லைன் |

4. Regulatory Compliance & Land Management Laws

5. Market Trend Analysis: The Future of Forage Harvesting

6. EVER-POWER Factory: Customization & Quality Assurance

ஹுலுன்புயர் பொருளாதார மற்றும் தொழில்நுட்ப மேம்பாட்டு மண்டலத்தில் அமைந்துள்ள எங்கள் உற்பத்தி வசதி, 32,000 சதுர மீட்டர்கள் மற்றும் அதிநவீன CNC லேசர் வெட்டும் இயந்திரங்கள், தானியங்கி வெல்டிங் கோடுகள் மற்றும் மின்னியல் பவுடர் பூச்சு கோடுகள் ஆகியவற்றைக் கொண்டுள்ளது. நாங்கள் வெறும் அசெம்பிளர் மட்டுமல்ல; நாங்கள் ஆழமான ஆராய்ச்சி மற்றும் மேம்பாட்டு திறன்களைக் கொண்ட ஒரு விரிவான உற்பத்தியாளர்.

தனிப்பயனாக்குதல் சேவைகள் (OEM/ODM): விவசாய நிலைமைகள் பிராந்தியத்திற்கு பிராந்தியம் மாறுபடும் என்பதை நாங்கள் புரிந்துகொள்கிறோம். தென் கொரிய சந்தைக்கு, நாங்கள் தனிப்பயனாக்க விருப்பங்களை வழங்குகிறோம், அவற்றுள்:

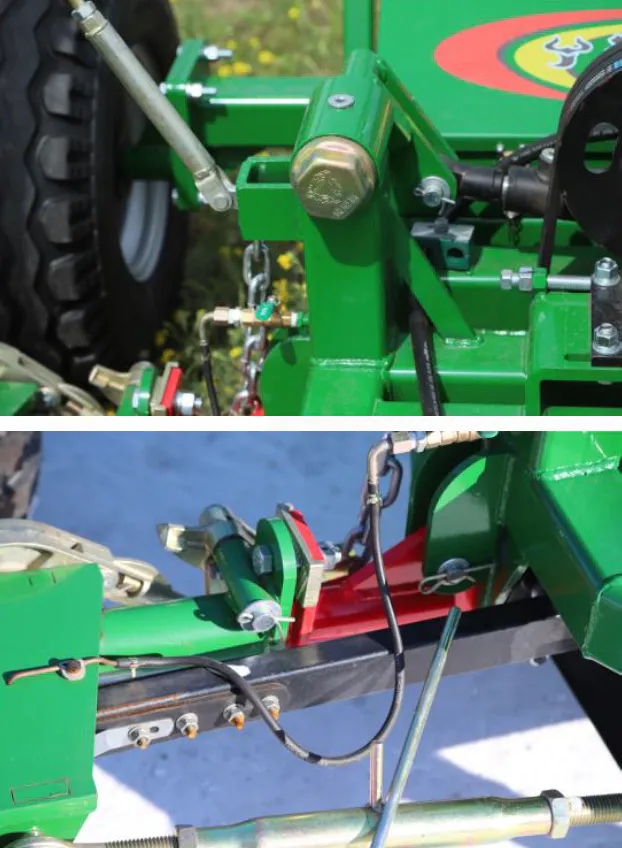

• ஹைட்ராலிக் தழுவல்: குறிப்பிட்ட LS அல்லது டேடாங் டிராக்டர் ஹைட்ராலிக் ஓட்டங்களுடன் பொருந்த வால்வு அழுத்தங்களை சரிசெய்தல்.

• டயர் மேம்பாடுகள்: ஆழமான சேற்று நெல் வயல்களுக்கு விருப்பமான அகலமான மிதக்கும் டயர்கள்.

• நிறம் & பிராண்டிங்: டீலர்கள் மற்றும் விநியோகஸ்தர்களுக்கான OEM பிராண்டிங் சேவைகள்.

நாங்கள் வைத்திருக்கிறோம் ISO9001 தர மேலாண்மை அமைப்பு சான்றிதழ் மேலும் தேசிய உயர் தொழில்நுட்ப நிறுவனமாக அங்கீகரிக்கப்பட்டுள்ளது. ஒவ்வொரு 9YG-2.24D பேலரும் ஏற்றுமதிக்கு முன் கடுமையான 48 மணிநேர தொடர்ச்சியான செயல்பாட்டு சோதனைக்கு உட்படுகிறது, இது வருகையின் போது பூஜ்ஜிய குறைபாடுகளை உறுதி செய்கிறது.

7. Related products

7.1 Gearbox:

இணக்கமான மாதிரிகள்: EP-FK263 (சதுர பேலர்), EP-RC30 தொடர் (சுற்று பேலர், பரிமாற்ற விகிதம் 1:2, 35mm 6-ஸ்ப்லைன் ஷாஃப்டுடன் இணக்கமானது).பயன்பாடு: நியூ ஹாலந்து 630 அல்லது ஜான் டீரெ 535 க்கு ஏற்ற, PTO சக்தியை பேலிங் பொறிமுறைக்கு அனுப்புகிறது. அளவுருக்கள்: முறுக்குவிசை > 500 Nm, 20% எரிபொருள் சேமிப்பு.இந்த கியர்பாக்ஸை ஏன் தேர்வு செய்ய வேண்டும்: தனிப்பயனாக்கக்கூடிய அளவு (250-300 மிமீ வரை குறைக்கக்கூடியது), பிசுபிசுப்பான மாசுபாடுகளுக்கு (ரப்பர் புகை) எதிர்ப்பு, IP65 பாதுகாப்பு. PTO ஷாஃப்ட்:இணக்கமான மாதிரிகள்: EP-PTO தொடர் (1-3/8″ Z6 ஸ்ப்லைன், சரிசெய்யக்கூடிய நீளம் 600-1200மிமீ).பயன்பாடு: டிராக்டரை பேலர் மெயின் டிரைவோடு இணைக்கிறது, 9YG-1.0C வகைக்கு ஏற்றது. முறுக்குவிசை பரிமாற்ற திறன் >95%, SAE/EURO விளிம்புகளுடன் இணக்கமானது.இது ஏன் பொருத்தமானது: நீர்ப்புகா வடிவமைப்பு, ஈரமான சிலேஜ் செயல்பாடுகளுக்கு ஏற்றது; வீஸ்லர் தொடருடன் மாற்றக்கூடியது.

7.2 சங்கிலிகள் & ஸ்ப்ராக்கெட்டுகள்:

இணக்கமான மாதிரிகள்: ANSI சங்கிலிகள், EP-Sprocket உடன் (சுருதி 12.7-19.05mm, ரோலர் விட்டம் 10-12mm).பயன்பாடு: கன்வேயர் பெல்ட்கள் அல்லது பிணைப்பு வழிமுறைகளில் பயன்படுத்தப்படுகிறது, சதுர/சுற்று பேலர் வைக்கோல் கடத்தலுக்கு ஏற்றது. அகலம் 25-40 மிமீ, அணிய-எதிர்ப்பு எஃகு பொருள்.இது ஏன் பொருத்தமானது: கோபெல்கோ அல்லது HF குழும உபகரணங்களுடன் இணக்கமானது, சங்கிலி உடைப்பு அபாயத்தைக் குறைக்கிறது; சிலேஜுக்கு உணவு தர விருப்பம் கிடைக்கிறது.

7.3 Couplings:

இணக்கமான மாதிரிகள்: EP-இணைப்பு 200 தொடர் (முறுக்குவிசை பொருத்தம் 500-1000 Nm).பயன்பாடு: கியர்பாக்ஸை பேலிங் ரோலருடன் இணைக்கிறது, அதிர்வைக் குறைக்கிறது.இது ஏன் பொருத்தமானது: உயர் சுழற்சி நீடித்து உழைக்கும் தன்மை, பாண்டியோலி & பவேசியுடன் இணக்கமானது.

7.4 ஹைட்ராலிக் சிலிண்டர்:

ஹைட்ராலிக் சிலிண்டர்: EP-HC தொடர் (துளை 50-100மிமீ, ஸ்ட்ரோக் 300-600மிமீ), பேல் தூக்குதலுக்கு ஏற்றது.தாங்கு உருளைகள் மற்றும் முத்திரைகள்: 6208-2RS தாங்கு உருளைகள், L10 ஆயுள் >10000 மணிநேரம், தூசி புகாத முத்திரை.இணக்கத்தன்மை அட்டவணை: Comer 250T உடன் முழுமையாக மாற்றக்கூடியது (முறுக்குவிசை பொருத்தம், விலையில் 35% மட்டுமே); flange வட அமெரிக்க 4-போல்ட் PTO வடிவத்துடன் பொருந்துகிறது.* பொறுப்புத் துறப்பு: மேலே குறிப்பிடப்பட்டுள்ள பிற பிராண்ட் பெயர்கள் விளக்க நோக்கங்களுக்காக மட்டுமே வழங்கப்பட்டுள்ளன. இந்த பிராண்ட் பெயர்களைக் கொண்ட அசல் தயாரிப்புகள் அல்லது உபகரணங்களை நாங்கள் வழங்குவதில்லை.* வேலை நிலைமைகளைப் பொறுத்து அளவுருக்கள் மாறுபடும்; தயவுசெய்து உண்மையான வரைபடங்களைப் பார்க்கவும். தேர்ந்தெடுப்பதற்கு முன் இடைமுக பரிமாணங்களை உறுதிப்படுத்த பரிந்துரைக்கப்படுகிறது.

8. Frequently Asked Questions (FAQ)

Q1: How much does the 9GD-2.5 Towed Single-Blade Lawn Mower cost for delivery to Busan port?

A1: The **Reciprocating cutter bar mower price** for the 9GD-2.5 varies based on order volume and customization. Generally, for a single unit, the price is highly competitive for the Korean market. To get an exact quote including shipping and insurance to Busan or Incheon, please click our ‘Get a Quote’ button to speak with a sales representative.

Q2: Where can I find a reliable Towed Single-Blade Lawn Mower manufacturer that ships directly to South Korea?

A2: Jiujia Machinery is a direct-to-market manufacturer with extensive experience exporting to the South Korean agricultural sector. We handle all international logistics and provide direct factory support for the 9GD series, ensuring you avoid middleman markups while receiving genuine industrial-grade equipment.

Q3: What is the recommended tractor horsepower for operating the 9GD-2.5 lawn mower on sloped pastures?

A3: For the 9GD-2.5 model, the optimal power requirement is between 25 and 40 HP (18.4-30 kW)[cite: 1]. If you are operating in sloped regions like the Gangwon highlands, we recommend using a tractor at the higher end of that range (35-40 HP) to ensure consistent PTO speed and towing stability.

Q4: Which reciprocating blade material is best for high-moisture sudangrass harvesting in Korea?

A4: We utilize heat-treated manganese steel for all 9GD-2.5 cutter bars. This material is specifically chosen for its ability to maintain a sharp edge even when cutting high-moisture forage, preventing the “clogging” that often occurs with standard carbon steel blades in humid Korean summers.

Q5: How do I choose between the 9GD-2.5 and the upgraded version for my farm’s specific needs?

A5: The standard 9GD-2.5 is designed for maximum cost-efficiency and reliability using a traditional crank-rod system. [cite_start]If your priority is a proven, high-productivity workhorse (up to 2.0 hm²/h) [cite: 1] with simpler maintenance requirements, the standard 9GD-2.5 is the ideal choice for most commercial forage farms.

Q6: What are the maintenance requirements for the crank mechanism in the 9GD-2.5 lawn mower?

A6: To ensure longevity, the primary maintenance task is daily lubrication of the crank pin and connecting rod bearings. We also recommend checking the tension of the drive belt every 20 operational hours. [cite_start]These simple steps prevent mechanical wear and ensure your machine maintains its 5-8 km/h working speed[cite: 1].

Q7: Does Jiujia offer product customization for different tractor hitch standards used in Korea?

A7: Yes! While the 9GD-2.5 comes with a standard towed hitch, we can customize the connection points to match specific LS Mtron or Daedong tractor standards. We can also adjust the PTO spline configuration to ensure a seamless “plug-and-play” experience for your existing fleet.

Q8: When is the best time to replace the cutter bar guards on the 9GD-2.5?

A8: Guards should be inspected every season. If you notice a “tearing” rather than a “cutting” of the grass, or if the stationary edges have become rounded, it is time for a replacement. [cite_start]Maintaining sharp guards ensures you stay within the 30-80 mm cutting height range effectively[cite: 1].

Q9: What safety certifications does the 9GD-2.5 hold for international agricultural equipment markets?

A9: Our equipment is manufactured under ISO 9001 quality management systems and meets the essential safety requirements for international agricultural trade. We provide full technical documentation to assist with South Korean MAFRA safety audits and insurance requirements.

Q10: Why should I choose a towed single-blade mower over a standard rotary mower for livestock feed?

A10: Towed single-blade mowers use a reciprocating cut that preserves the stem’s vascular structure. This results in significantly higher forage quality and faster field drying times compared to rotary mowers, which can “beat” the grass and cause sap loss, especially in high-sugar crops like alfalfa.

Editor: PXY

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.