Beskrivning

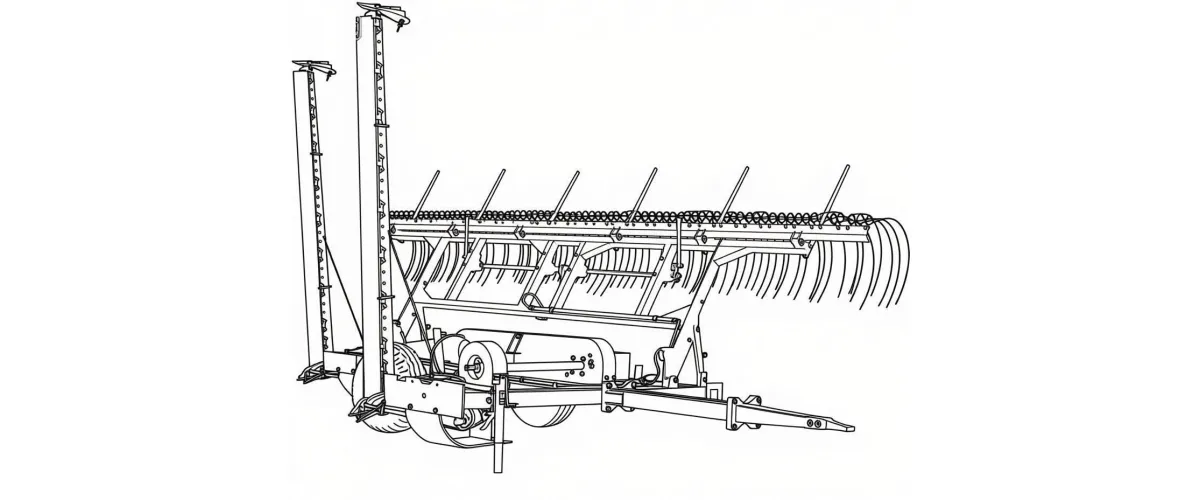

1. Technical Specifications: 9GL-2.5/2.9 Series

| Inga. | Punkt | Enhet | Specifikation |

|---|---|---|---|

| 1 | Modellnamn | / | 9GL-2.5 / 2.9 Towed Mower-Rake |

| 2 | Dragkrokstyp | / | Towed |

| 3 | Typ av skärstruktur | / | Fram- och återgående |

| 4 | Skärbredd | m | 2.5 |

| 6 | Raking Working Width | m | 2.9 |

| 7 | Arbetshastighetsområde | km/h | 6–7 |

| 8 | Produktivitet | hm²/h | Mowing: 1.2–1.44 / Raking: 1.5–1.8 |

| 9 | Genomsnittlig skärhöjd | mm | 60–70 |

| 10 | Matchande kraft | kW | 25–55 |

| 11 | Tractor PTO Speed | varv/min | 540 |

| 12 | Maskinvikt | kg | 920 |

| 13 | Number of Rake Teeth | st | 42 |

| 14 | Rake Tooth Spacing | mm | 71 |

| 15 | Overall Dimensions (L × W × H) | mm | — |

| 16 | Transport Condition Dimensions | mm | 3100 × 2920 × 2900 |

| 17 | Working Condition Dimensions | mm | 3100 × 5000 × 950 |

| 18 | Antal rörliga blad | st | 34 |

2. Key Facts & Capabilities

- Dual-Action Efficiency: Cuts and rakes forage in one operation, achieving productivity rates up to 1.8 hm²/h.

- Power Requirement: Optimized for mid-range tractors (25-55 kW), making it ideal for the “pull behind rake for tractor” category.

- Terrain Adaptability: Specifically designed for flat grasslands and gentle slopes, perfect for Jeolla and Chungcheong plains.

- Precision Engineering: Features a sensitive hydraulic lifting mechanism for obstacle avoidance and transport safety.

- Cost-Effective: Reduces labor hours and equipment wear by halving the required field passes.

3. Revolutionizing Harvest with the 9GL-2.5/2.9 Trailed Mower Rake

4. Engineering Excellence: Working Principles and Material Metallurgy

The operational success of the 9GL-2.5/2.9 model lies in its sophisticated synchronization of cutting and raking mechanisms driven by the tractor’s PTO shaft (540 r/min) and rear hydraulic output. The unit features a specialized offset traction frame that allows the mower to operate to the side of the tractor, preventing the tires from trampling the standing crop before it is cut—a common issue with inferior setups.

The cutter bar utilizes high-carbon alloy steel knife guards and serrated sections that undergo rigorous heat treatment to achieve a hardness of HRC 50-55, ensuring prolonged edge retention even in abrasive, sandy soil conditions often found in coastal farming regions. Following the cutter, the raking mechanism employs a series of curved spring-steel tines. These are not standard wire; they are crafted from 65Mn spring steel, known for its high fatigue strength and elasticity. As the crop is severed, the rake immediately gathers the material into fluffy, aerated windrows. This immediate windrowing is crucial for creating airflow, allowing the hay to cure evenly. The chassis is constructed from Q345B structural steel, providing the “heavy-duty trailed mower rake” characteristics necessary to endure vibration and terrain undulations without structural fatigue.

5. Global Compliance: Agricultural Machinery and Land Management Regulations

7. Market Trends: The Shift Towards Integrated Harvesting

The global agricultural machinery market is witnessing a decisive shift towards multi-functional implements, driven by rising fuel costs and labor shortages. In South Korea, where the rural population is aging and labor is scarce, the demand for “used trailed mower rake” and new integrated solutions has spiked by 15% year-over-year. Farmers are moving away from single-purpose machines towards units like the 9GL series that perform multiple tasks simultaneously.

This trend is not isolated; in the US and Europe, “pull behind rake for riding mower” and larger tractor-mounted combination units are dominating the market segment for small-to-medium acreage farms. The trend also favors “smart farming” compatibility—while the 9GL is a mechanical unit, its compatibility with modern GPS-guided tractors allows for precision windrowing, reducing waste. Furthermore, the push for organic dairy farming requires gentler handling of forage to preserve nutritional value, a requirement that rotary mowers struggle to meet but reciprocating mowers excel at. Investing in a 9GL-2.5/2.9 is investing in the future trajectory of efficient, sustainable agriculture.

8. Tractor & Component Compatibility

| Category | Details / Brand Compatibility |

|---|---|

| Tractor Brands (South Korea) | Fully compatible with LS Mtron, TYM, Daedong (Kioti), and Kukje Machinery tractors in the 35-75 HP range. |

| Tractor Brands (Global) | Compatible with John Deere (5E Series), Kubota (M Series), Massey Ferguson, and New Holland. |

| PTO Connection | Standard 1-3/8″ 6-Spline, 540 RPM. Adapters available for non-standard shafts. |

| Hydraulic Requirement | Requires 1 Rear Remote Valve (Double Acting recommended for lift control). |

| Replacement Parts | Knife sections compatible with generic sickle bar standards (Ford/New Holland style). Rake teeth compatible with universal 65Mn spring tine mounts. |

*Friskrivning: De andra varumärkena som nämns ovan anges endast i illustrativt syfte. Vi erbjuder inte originalprodukter eller utrustning med dessa varumärken.

9. Customer Success Story:

10. EVER-POWER Mower rake Manufacturer: Customization & Quality Assurance

Vår tillverkningsanläggning ligger i Hulunbuirs ekonomiska och tekniska utvecklingszon och sträcker sig över 32 000 kvadratmeter och är utrustad med toppmoderna CNC-laserskärmaskiner, automatiska svetslinjer och elektrostatiska pulverlackeringslinjer. Vi är inte bara en montör; vi är en heltäckande tillverkare med djupgående FoU-kapacitet.

Anpassningstjänster (OEM/ODM): Vi förstår att jordbruksförhållandena varierar beroende på region. För den sydkoreanska marknaden erbjuder vi anpassningsalternativ, inklusive:

• Hydraulisk anpassning: Justering av ventiltryck för att matcha specifika LS- eller Daedong-traktorns hydraulflöden.

• Däckuppgraderingar: Bredare flytdäck som tillval för risfält med djup lera.

• Färg och varumärke: OEM-varumärkestjänster för återförsäljare och distributörer.

Vi håller ISO9001-certifiering av kvalitetsledningssystem och har erkänts som ett nationellt högteknologiskt företag. Varje 9YG-2.24D-balpress genomgår ett rigoröst 48-timmars kontinuerligt drifttest före leverans för att säkerställa noll defekter vid ankomst.

11. Related products

11.1 Gearbox:

Kompatibla modeller: EP-FK263 (fyrkantsbalpress), EP-RC30-serien (rundbalpress, utväxlingsförhållande 1:2, kompatibel med 35 mm 6-splinesaxel).Användningsområde: Överför kraftuttagskraft till balpressmekanismen, lämplig för New Holland 630 eller John Deere 535. Parametrar: Vridmoment > 500 Nm, 20% bränslebesparing.Varför välja denna växellåda: Anpassningsbar storlek (reducerbar till 250-300 mm), resistent mot viskösa föroreningar (gummiångor), IP65-skydd. Kraftuttagsaxel:Kompatibla modeller: EP-PTO-serien (1-3/8″ Z6-spline, justerbar längd 600–1200 mm).Användningsområde: Ansluter traktorn till balpressens huvuddrivning, lämplig för typ 9YG-1.0C. Momentöverföringseffektivitet >95%, kompatibel med SAE/EURO-flänsar.Varför den är lämplig: Vattentät design, lämplig för våtensilage; utbytbar mot Weasler-serien.

11.2 Kedjor & Kedjehjul:

Kompatibla modeller: ANSI kedjor, med EP-drev (stigning 12,7–19,05 mm, rulldiameter 10–12 mm).Användningsområde: Används i transportband eller bindningsmekanismer, lämplig för transport av halm i fyrkants-/rundbalspressar. Bredd 25-40 mm, slitstarkt stålmaterial.Varför den är lämplig: Kompatibel med Kobelco- eller HF Group-utrustning, minskar risken för kedjebrott; livsmedelsklassat alternativ tillgängligt för ensilage.

11.3 Couplings:

Kompatibla modeller: EP-koppling 200-serien (momentanpassning 500-1000 Nm).Användning: Ansluter växellådan till balpressvalsen, dämpar vibrationer.Varför den är lämplig: Hållbar mot höga cykler, kompatibel med Bondioli och Pavesi.

11.4 Hydraulcylinder:

Hydraulcylinder: EP-HC-serien (diameter 50–100 mm, slaglängd 300–600 mm), lämplig för ballyftning.Lager och tätningar: 6208-2RS-lager, L10 livslängd >10000 timmar, dammtät tätning.Kompatibilitetstabell: Helt utbytbar med Comer 250T (momentmatchning, endast 35% av priset); flänsen matchar nordamerikanskt 4-bults kraftuttagsmönster.* Friskrivningsklausul: De andra varumärkena som nämns ovan anges endast i illustrativt syfte. Vi erbjuder inte originalprodukter eller utrustning med dessa varumärken.* Parametrarna varierar beroende på arbetsförhållanden; se de faktiska ritningarna. Det rekommenderas att bekräfta gränssnittets dimensioner innan val.

12. Frequently Asked Questions (FAQ)

Q1. What is the estimated price for the 9GL-2.5 mower rake, including shipping to Incheon, South Korea?

A1. The FOB price fluctuates based on raw material costs, but we offer factory-direct pricing. For a precise CIF Incheon quote including customs clearance documentation, please contact our sales team via the “Get a Quote” button.

Q2. Which tractor horsepower is strictly required to operate the 9GL-2.9 heavy-duty trailed mower rake efficiently?

A2. To operate the 9GL-2.9 efficiently without straining your engine, we recommend a tractor with at least 35HP, though 50-55HP is ideal for handling hilly terrain and maintaining consistent PTO speed.

Q3. How does this reciprocating mower rake compare to a disc mower in terms of crop quality and leaf retention?

A3. Unlike disc mowers that shatter leaves due to high impact speed, our reciprocating sickle bar creates a scissor-like cut, preserving leaf integrity, which is crucial for high-protein feed like alfalfa.

Q4. Where can I buy replacement teeth or knife sections for this trailed mower rake if I am in Australia?

A4. We supply a comprehensive spare parts kit with every unit. Additionally, our components use standard international sizing, so you can find compatible knife sections at local agricultural supply stores or order directly from us via express air freight.

Q5. Can this machine function as a pull-behind rake for a tractor on uneven or rocky terrain safely?

A5. While it handles gentle slopes well, reciprocating cutters are sensitive to large rocks. However, our hydraulic lift system allows the operator to quickly raise the cutter bar over obstacles, preventing damage.

Q6. What is the Minimum Order Quantity (MOQ) for a customized OEM order of these mower rakes?

A6. For standard units, our MOQ is 1 set. For OEM customization (custom color, branding, or chassis modification), the MOQ is typically 5 sets to optimize production costs.

Q7. When is the best time to order to ensure delivery before the harvest season in the Northern Hemisphere?

A7. Due to high demand, we recommend placing orders 2-3 months before your harvest season begins. For Spring harvest, ordering in late Winter ensures your equipment arrives and is assembled in time.

Q8. How do I connect the hydraulic system if my tractor only has one rear hydraulic output valve?

A8. The 9GL series typically requires one set of hydraulic outlets for the lift cylinder. If your tractor lacks outlets, we can provide a manual mechanical lift conversion or a diverter valve kit as an option.

Q9. Is there a warranty for the gearbox and structural components of the 9GL-2.5 trailed mower?

A9. Yes, EVER-POWER provides a 12-month warranty on the main structural frame and the gearbox. Wear parts like knife sections and rake tines are excluded but are supplied as spares.

Q10. Do you provide installation manuals or video guides for assembling the machine upon arrival?

A10. Absolutely. We provide a detailed PDF manual in English (and other languages upon request) and a step-by-step video installation guide to ensure you can assemble the trailed mower rake easily.

Redaktör: PXY