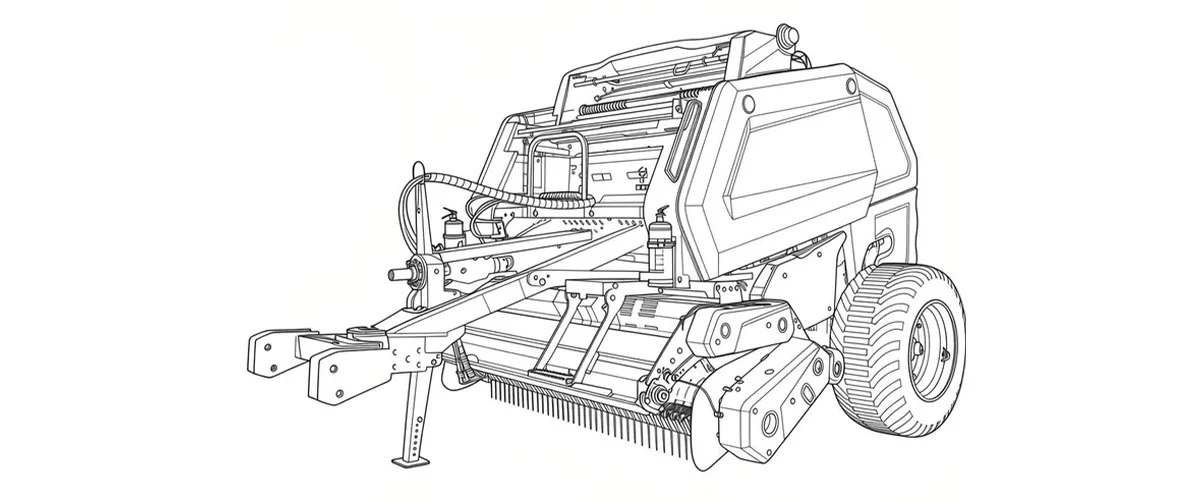

Пресс-подборщик EP-9YG-2.24D S9000

The 9YG-2.24D S9000 Round Baler offers speed, precision, and operational efficiency for modern farms. It’s built to handle the most demanding environments, providing farmers with a reliable, cost-effective solution that delivers results season after season. Whether you’re looking to streamline operations, reduce labor costs, or improve bale quality, the S9000 is your trusted partner in the field.

1. Technical Specifications (Model: 9YG-2.24D S9000 Round baler)

| Нет. | Элемент | Единица | Спецификация |

|---|---|---|---|

| 1 | Название модели | / | 9YG-2.24D Round Baler (S9000) |

| 2 | Тип сцепного устройства | / | Трейловый |

| 3 | Ширина звукоснимателя | мм | 2240 |

| 4 | Тип конструкции захвата | / | Подборщик зубьев |

| 5 | Структура механизма подачи | / | Ротор подачи + роликовый тип |

| 6 | Тип камеры сжатия | / | Роликовая камера |

| 7 | Ширина камеры сжатия | мм | 1400 |

| 8 | Диаметр камеры сжатия | мм | Φ1200 |

| 9 | Количество рабочих компонентов ролика | шт. | 18 (роликов) |

| 10 | Диаметр ролика | мм | Φ222 |

| 11 | Метод прессования | / | Сетчатая обертка |

| 12 | Требуемая мощность | кВт | 55–100 |

| 13 | Конструкционный вес | кг | 4262 |

| 14 | Скорость вращения выходного вала ВОМ | об/мин | 720 |

| 15 | Габариты (Д × Ш × В) | мм | 4240 × 3010 × 2450 (working condition) |

| 16 | Контроль плотности кормовой базы | / | Управление с помощью датчиков |

| 17 | Размер тюка (диаметр × ширина) | мм | Φ1300 × 1400 |

| 18 | Плотность тюков | кг/м³ | 100–200 |

| 19 | Производительность | тюк/ч | 40–100 |

| 20 | Колесная база | мм | 2600 |

| 21 | Рабочая скорость | км/ч | 5–35 |

| 22 | Спецификация сетчатой обертки | м | 2000 × 1,4 / рулон |

2. Key Engineering Facts

- High Compression System: Features dual-side 20A heavy-duty chains in the rear chamber, achieving bale weights between 250kg to 500kg (500-1000 jin).

- Адаптивность к рельефу местности: The innovative traction device allows for a 100° horizontal steering angle and a 30° lateral tilt limit, preventing driveline bind on hills.

- Massive Throughput: Capable of producing 40 to 100 bales per hour with a pick-up width of 2240mm.

- Robust Build: Weighs 4262 kg with a reinforced chassis, designed for tractors in the 55-100 kW power range.

- Advanced Binding: Utilizes an automatic net wrap system for tighter, weather-resistant bales.

3. In-Depth Product Analysis & Working Principle

Revolutionary Traction & Driveline Engineering

The most critical innovation in the 9YG-2.24D Round Baler S9000 model lies in its specialized traction and driveline system. In traditional round balers, the connection between the tractor and the implement is often a rigid point of failure, particularly when operating on the terraced fields or undulating hills common in South Korea's Gangwon-do or Jeolla-do provinces. The S9000 addresses this with a proprietary traction device engineered to withstand a maximum torque of 1000nm. This is not merely a stronger hitch; it is a dynamic articulation point. It offers a horizontal steering angle of 100 degrees, allowing for incredibly tight turning radii without disengaging the PTO. More importantly, it accommodates a lateral tilt (tractor vs. baler angle) of up to 30 degrees.

This "Super Floating" capability ensures that even if the tractor is on a slope and the baler is in a dip, the power transmission remains smooth, preventing the catastrophic driveshaft snapping that plagues lesser machines. This design dramatically reduces downtime and maintenance costs associated with universal joint failures.

Compression Mechanism & Material Science

At the heart of the S9000’s performance is its compression chamber, which utilizes a roller-type formation mechanism driven by a reinforced dual-side 20A chain system. We have moved beyond standard industrial chains to use high-grade alloy steel chains that have undergone specialized heat treatment (carburizing and quenching) to increase wear resistance and tensile strength.

The chamber houses 18 high-strength steel rollers (Φ 222mm), which are essential for creating the "bale rotation" effect. As forage enters the chamber via the 2240mm pick-up and auger system, these rollers initiate a tumbling action. The 20A chains apply immense, consistent pressure, compacting the material from the core outwards.

For silage production, High density means less air is trapped inside the bale, promoting rapid anaerobic fermentation and preventing spoilage.

For dry straw, this density translates to maximized transport efficiency, allowing farmers to load more weight per truck, significantly reducing logistics costs in the biomass energy supply chain.

6. Market Trend Analysis: The Shift to High-Density Baling

The global agricultural machinery market is witnessing a decisive shift towards "Smart Baling" and high-density biomass logistics. In developed agricultural economies, the trend is moving away from small square bales towards large round bales due to labor shortages and the need for mechanized handling. Specifically in East Asia (South Korea, Japan, China), there is a growing demand for machinery that can handle "wet crop" or silage (balage). Traditional dry hay balers often fail in these conditions due to clogging and insufficient compression.

The trend favors machines like the S9000 that utilize roller compression over belt compression for wet crops, as rollers provide better grip and rotation for heavy, damp material. Furthermore, the integration of biomass energy plants requires straw to be baled with maximum density to reduce the carbon footprint of transportation. The S9000’s capability to reach 200 kg/m³ places it at the forefront of this eco-efficiency trend, bridging the gap between field residue management and renewable energy production.

4. Global & Local Regulatory Compliance

In our primary target market, South Korea, the Ministry of Agriculture, Food and Rural Affairs (MAFRA) has implemented stringent policies regarding agricultural byproduct management to combat fine dust pollution (PM2.5). Open burning of rice straw and corn stalks is strictly prohibited in many provinces. The 9YG-2.24D S9000 is perfectly aligned with these regulations. Its high pick-up efficiency ensures that straw is removed from the field cleanly, ready for biomass power generation or livestock feed, supporting the government's "Resource Circulation" initiatives. Furthermore, the machine's safety features meet the Korea Agricultural Machinery Industry Cooperative (KAMICO) safety standards.

Globally, our manufacturing process adheres to ISO 9001 quality management systems, ensuring that every unit exported to Europe, the Americas, or Asia meets the safety requirements for heavy machinery, including emergency stop protocols and protective shielding for moving parts (as per EU Machinery Directive 2006/42/EC).

5. Compatibility & Application Scenarios

The S9000 is designed for versatility. Below is a compatibility matrix for tractors and operational environments.

| Tractor Brand Class | PTO Specification | Hydraulic Output | Тип сцепного устройства |

|---|---|---|---|

| John Deere 6M Series (or equivalent) | 1-3/8" 6-Spline, 540/720 RPM | Min 2 sets double-acting valves | Drawbar / 2-Point Hitch |

| Kubota M Series (High HP) | 1-3/8" 6-Spline, 720 RPM | Standard Flow | Drawbar |

| LS Tractor / TYM (Korean Brands) | Standard 6-Spline | Compatible | Drawbar |

Customer Success Story:

“We’ve been using the 9YG-2.24D S9000 for over 6 months now, and the performance has been outstanding. The high-density bales are a game-changer, reducing our transport costs and increasing our efficiency by at least 25%. The net wrap system is fantastic.”

— Farm Manager, South Korea

“We operate in some of the hilliest terrain in New Zealand, and the S9000’s 100° steering angle has made a huge difference. No more worrying about driveline binding or PTO disengagement on slopes. It's a durable, well-engineered machine that adapts to our tough farming conditions.”

— Agricultural Operations Director, New Zealand

“The compression system on this baler is unlike anything we’ve used before. It packs our forage into tight bales, which has dramatically improved storage efficiency. The S9000 has been a great addition to our fleet, and we’ve noticed a significant reduction in labor costs due to its automated features.”

— Farm Owner, United States

“The 9YG-2.24D S9000 has exceeded our expectations in silage production. The high-density compression means less air in the bales, promoting faster fermentation and preserving the quality of our feed. It’s well-suited for our wet crops, especially in high-humidity environments.”

— Feedlot Manager, Australia

“We've been using the S9000 for about a year now, and it's been nothing short of a workhorse. The ease of use, combined with the exceptional bale density and net wrapping technology, has made our hay and straw handling much more efficient. The machine has held up even under tough weather conditions.”

— Hay Farmer, United Kingdom

“Working on large-scale farm operations, we need equipment that can keep up with high demand. The S9000 handles our workload effortlessly, producing 80–100 bales per hour. It's a reliable, high-performance machine.”

— Large-Scale Farm Manager, Canada

10. About us | EVER-POWER: Your Partner in Custom Agricultural Solutions

At EVER-POWER, we are not just assembling parts; we are defining the standard for agricultural component manufacturing. Our facility is a state-of-the-art intelligent manufacturing hub, equipped with CNC laser cutting machines, automated welding robot lines, and electrostatic powder coating systems. We understand that one size does not fit all.

Whether you require a specific color scheme to match your OEM brand, modifications to the pick-up width for specialized row crops, or adjustments to the hydraulic interface for regional tractor compatibility, our engineering team is ready to deliver. We offer comprehensive OEM/ODM services, ensuring that the 9YG-2.24D baler fits seamlessly into your product lineup or farm operation.

Сертификаты и награды:

• Сертификация ISO 9001

• Сертификат национального высокотехнологичного предприятия

• Право на самостоятельное осуществление импортно-экспортных операций

• Сертификация CE

11. Related products

11.1 Gearbox:

Совместимые модели: EP-FK263 (квадратный пресс-подборщик), серия EP-RC30 (круглый пресс-подборщик, передаточное число 1:2, совместим с 35-мм 6-шлицевым валом).Применение: Передает мощность ВОМ на механизм прессования тюков, подходит для New Holland 630 или John Deere 535. Параметры: Крутящий момент > 500 Нм, экономия топлива 20%.Почему стоит выбрать именно этот редуктор: регулируемый размер (уменьшается до 250-300 мм), устойчивость к вязким загрязнениям (резиновым испарениям), степень защиты IP65. Вал отбора мощности:Совместимые модели: серия EP-PTO (шлицы Z6 1-3/8 дюйма, регулируемая длина 600-1200 мм).Применение: Соединяет трактор с главным приводом пресс-подборщика, подходит для типа 9YG-1.0C. КПД передачи крутящего момента >95%, совместим с фланцами SAE/EURO.Почему он подходит: Водонепроницаемая конструкция, подходит для работы с влажным силосом; может быть заменен на аналогичные модели серии Weasler.

11.2 Цепи & Зубчатые колеса:

Совместимые модели: ANSI #50/#60 цепис EP-звездочкой (шаг 12,7-19,05 мм, диаметр ролика 10-12 мм).Применение: Используется в конвейерных лентах или обвязочных механизмах, подходит для транспортировки соломы в квадратных/круглых тюках. Ширина 25-40 мм, износостойкая сталь.Почему это подходит: Совместимо с оборудованием Kobelco или HF Group, снижает риск обрыва цепи; доступен вариант пищевого качества для силоса.

11.3 Couplings:

Совместимые модели: муфты EP-Coupling серии 200 (согласование крутящего момента 500-1000 Нм).Применение: Соединяет редуктор с прессовальным роликом, гасит вибрацию.Почему это подходит: Высокая износостойкость, совместимость с Bondioli и Pavesi.

11.4 Гидравлический цилиндр:

Гидравлический цилиндр: Серия EP-HC (диаметр цилиндра 50-100 мм, ход поршня 300-600 мм), подходит для подъема тюков.Подшипники и уплотнения: подшипники 6208-2RS, ресурс L10 >10000 часов, пылезащитное уплотнение.Таблица совместимости: Полностью взаимозаменяема с Comer 250T (совпадение крутящего момента, цена всего 35%); фланец соответствует североамериканской схеме крепления ВОМ с 4 болтами.* Примечание: Указанные выше торговые марки приведены исключительно в иллюстративных целях. Мы не предлагаем оригинальную продукцию или оборудование, выпускаемые под этими торговыми марками.* Параметры могут различаться в зависимости от условий эксплуатации; пожалуйста, сверяйтесь с фактическими чертежами. Рекомендуется подтвердить размеры интерфейса перед выбором.

Frequently Asked Questions (FAQ)

Q1. How does the S9000 round baler's wide-angle traction device specifically benefit farming operations in South Korea's hilly terrains?

A1. The S9000 features a specialized traction device with a 100° horizontal steering angle and a 30° vertical tilt. This allows the baler to articulate independently from the tractor on uneven Korean paddies or terraced fields, preventing the driveshaft from binding or snapping during tight turns and slope changes.

Q2. What is the estimated price or cost range for purchasing the 9YG-2.24D round baler for export to Asian markets?

A2. The price of the 9YG-2.24D varies based on customization options, shipping logistics to specific Asian ports, and current raw material costs. For a precise commercial quote including CIF terms to Incheon or Busan, please contact our sales team directly via the inquiry button.

Q3. Which types of crops can the S9000 round baler handle effectively besides standard wheat straw?

A3. The S9000 is highly versatile and engineered to handle corn stalks (maize stover), alfalfa, wet rice straw, pasture grass, and reed. Its heavy-duty roller and chain system is specifically designed to compress tough, coarse materials found in diverse agricultural sectors.

Q4. What maintenance is required for the dual-side 20A heavy-duty chain system to ensure long-term durability?

A4. While the 20A chains are heat-treated for durability, we recommend checking chain tension after every 10 hours of operation and applying proper lubrication. The automatic oiling system should be kept filled. Regular inspection ensures the high-density compression mechanism remains efficient for years.

Q5. Does the S9000 round baler come with local support or spare parts availability for international buyers?

A5. Yes, EVER-POWER is expanding its global footprint. We provide a comprehensive spare parts kit with every machine. For international buyers, we offer express shipping for replacement parts and have digital technical manuals and video support to assist local mechanics with repairs.

Q6. How does the automatic net wrapping system on the S9000 compare to traditional twine binding in terms of efficiency?

A6. The automatic net wrap system on the S9000 significantly reduces binding time to just a few seconds per bale compared to minutes with twine. Net wrapping also provides better weather protection, maintains bale shape better during transport, and reduces leaf loss, preserving nutritional value.

Q7. Can you provide a supplier quote for a customized S9000 with specific color branding for an OEM partnership?

A7. Absolutely. As a source manufacturer, we specialize in OEM/ODM services. We can customize the machine's color, branding, and certain technical specifications to align with your product line. Please submit your requirements through our contact form for a tailored supplier quote.

Ready to Upgrade Your Forage Harvesting Efficiency?

Contact EVER-POWER today for technical consultations, dealership opportunities, or a direct price quote on the S9000 Round Baler.

Редактор: PXY