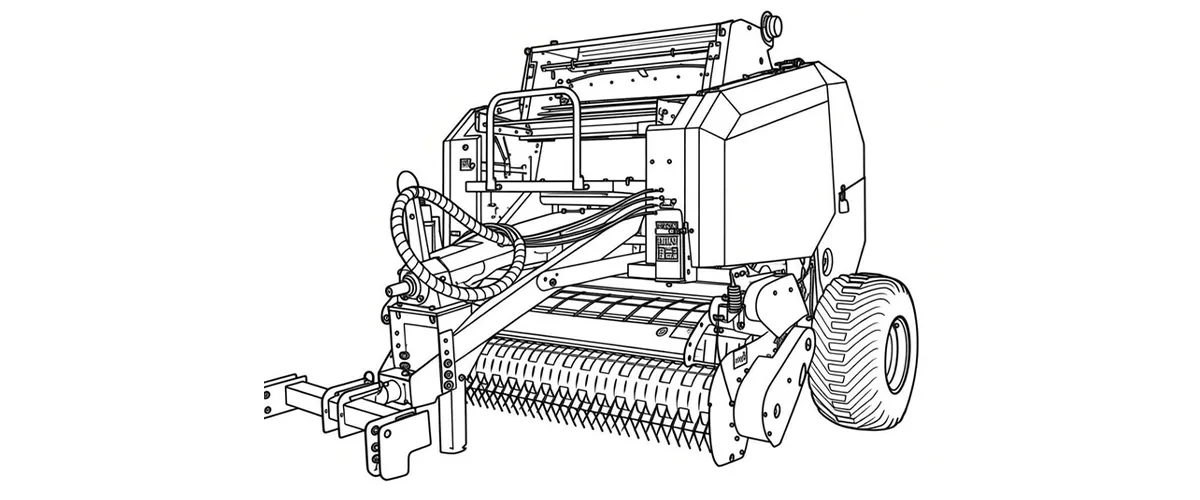

Пресс-подборщик EP-9YG-1.0

The 9YG-1.0 Round Baler represents a significant leap in agricultural engineering, specifically tailored for the intricate terrain and crop varieties found in East Asia, particularly South Korea. Unlike traditional models, this machine utilizes a proprietary “Axial Flow” semi-forced feeding mechanism, eliminating the need for cam tracks and guard rings, which historically are high-maintenance components.

This design innovation not only doubles the operational efficiency but also significantly reduces the probability of clogging—a common issue when harvesting wet rice straw or dense corn stalks. With a pickup width of 1900mm and a compact bale size of Φ1100×1000mm, it is perfectly sized for transport and storage in space-constrained environments. Engineered by EVER-POWER, this baler offers a robust solution for farmers seeking to maximize biomass recovery while minimizing fuel consumption and downtime.

1. EVER POWER Exclusive Specifications

| Item / Feature | Единица | Specification (9YG-1.0) |

|---|---|---|

| Название модели | / | 9YG-1.0 Round Baler |

| Тип сцепного устройства | / | Трейловый |

| Ширина звукоснимателя | мм | 1900 |

| Тип конструкции захвата | / | Ball Type |

| Feeding Mechanism | / | Ротор подачи + роликовый тип |

| Ширина камеры сжатия | мм | 1000 |

| Диаметр камеры сжатия | мм | Φ1000 |

| Number of Compression Rollers | шт. | 16 (rollers) |

| Диаметр ролика | мм | Φ222 |

| Метод привязки | / | Сетчатая обертка |

| Matched Power | кВт | 48–80 |

| Конструкционный вес | кг | 2640 |

| Скорость ВОМ | об/мин | 720 |

| Габариты (Д × Ш × В) | мм | 3750 × 2300 × 2020 |

| Контроль плотности кормовой базы | / | Управление с помощью датчиков |

| Размер тюка (диаметр × ширина) | мм | Φ1100 × 1000 |

| Плотность тюков | кг/м³ | 115–200 |

| Производительность | bales/h | 40–100 |

| Колесная база | мм | 2045 |

| Рабочая скорость | км/ч | 5–20 |

| Спецификация сетчатой обертки | м | 2000 × 1.25 / roll |

2. Key Engineering Facts

- Innovative Feeding System: Features a unique "Axial Flow" semi-forced feeding structure with no cams or guard rings, reducing power loss and maintenance costs.

- Optimal Bale Density: Produces bales with a density of 115–200 kg/m³, ideal for both dry storage and silage fermentation requirements in the Korean climate.

- High Throughput: Capable of producing 40 to 100 bales per hour, doubling the efficiency of conventional balers in its class.

- Versatile Crop Handling: Expertly designed for corn stalks, rice straw, wheat, and soybeans, capable of handling standing corn stalks without prior raking.

- Compact & Transportable: Bale weight ranges from 100kg to 200kg (200-400 catties), making manual handling and small-truck transport feasible.

3. Advanced Working Principle and Technological Superiority

The core competitive advantage of the 9YG-1.0 Round Baler lies in its revolutionary "Axial Flow" semi-forced feeding mechanism. Traditional balers often rely on complex cam-track pickup systems, which are prone to mechanical wear and require frequent lubrication and part replacement, especially when operating in the dusty or muddy conditions often found in South Korean rice paddies post-harvest. The 9YG-1.0 eliminates the cam and guard ring entirely. Instead, it utilizes a sophisticated rotor and beater roller combination that forces crop material directly into the compression chamber. This direct-flow path significantly reduces friction and resistance, allowing for smoother material intake even at higher ground speeds.

Furthermore, the compression chamber is constructed using 16 high-strength steel rollers (Φ222mm diameter). Unlike belt balers that can slip under high tension or variable crop moisture conditions, the fixed-chamber roller design ensures consistent bale rotation and formation. This is particularly crucial for the agricultural landscape in Korea, where straw is often harvested with varying moisture content. The mechanical locking of the tailgate, combined with the hydraulic density control sensors, ensures that every bale achieves the target density of up to 200 kg/m³. This high density is essential for excluding oxygen in silage bales, thereby promoting better fermentation and higher feed quality for livestock. The integration of a net wrapping system further streamlines the process, reducing the time spent per bale compared to twine tying, and providing better weather protection for outdoor storage.

4. Application Scenarios

1. Rice Straw Collection in Paddy Fields

Description: After the rice harvest, the 9YG-1.0 Round Baler is ideal for collecting rice straw directly from paddy fields. The machine’s powerful rotor and beater system ensure smooth operation in the damp conditions typically found in rice paddies, without causing blockages.

Benefit: Reduces labor and fuel consumption by directly picking up straw without pre-raking, and helps in recycling straw into valuable livestock feed or bedding.

2. Corn Stalk Harvesting for Silage

- Description: The 9YG-1.0 is highly effective for harvesting standing corn stalks in dry or wet conditions. It can directly cut and bale corn stalks without the need for a pre-cutting operation.

Benefit: Increases efficiency and productivity by eliminating multiple passes over the field, ensuring high-density bales suitable for silage fermentation.

3. Alfalfa and Grass Hay Baling

Description: Ideal for collecting dry or semi-dry alfalfa or grass hay from pastures, the 9YG-1.0 is designed to handle these crops with ease, forming compact bales that are easy to store and transport.

Benefit: Ensures fast and efficient hay collection, reducing the risk of leaf loss and ensuring optimal forage quality for livestock.

4. Wheat Straw for Bedding

- Description: The baler can be used to collect wheat straw after the grain harvest. This straw can be used as bedding material for animals or as a biofuel for heating purposes.

- Benefit: Maximizes the use of every crop, turning waste material into valuable resources, and reducing environmental impact by preventing straw burning.

5. Soybean Residue Baling

- Description: After soybean harvests, the 9YG-1.0 can collect the soybean residues left in the field. This residue can be used as a feedstock for bioenergy production or livestock feed.

- Benefit: Helps farmers make the most of crop residues by baling and recycling them into useful by-products.

6. Mixed Farming Operations

- Description: For farms that grow multiple types of crops such as corn, wheat, and hay, the 9YG-1.0 Round Baler can be used to collect various residues efficiently, making it a versatile addition to mixed farming operations.

- Benefit: Reduces the need for multiple types of equipment, offering cost savings and simplifying farm management.

7. Biomass Energy Production

- Description: The 9YG-1.0 is an excellent tool for preparing biomass materials like corn stalks, wheat straw, or rice straw, which can be converted into renewable energy.

- Benefit: Helps farmers contribute to the growing bioenergy industry by efficiently preparing materials for biomass conversion, reducing waste, and improving energy sustainability.

8. Dairy & Livestock Farm Forage Collection

- Description: The 9YG-1.0 Round Baler is commonly used on dairy and livestock farms to collect high-quality forage for feeding cows, sheep, and other livestock. It is especially effective for creating compact bales of silage.

- Benefit: Improves forage storage and handling, maintaining the nutritional integrity of the feed and minimizing waste.

9. Post-Harvest Waste Management

- Description: After the main crop has been harvested, the 9YG-1.0 can be used to collect the residual crop waste, such as leaves and stems, which would otherwise be left to decompose.

- Benefit: Reduces the environmental impact of crop residue burning and provides farmers with an opportunity to turn waste into valuable resources for composting or animal feed.

10. Small-Scale Custom Baling Services

- Description: For agricultural service providers offering baling services to multiple small-scale farms, the 9YG-1.0 is an ideal machine. Its compact size and versatile capabilities make it an excellent tool for custom baling in various crop types.

- Benefit: Serves multiple clients with diverse crop needs, increasing profitability and business growth for agricultural service providers.

5. Market Analysis: South Korean Agriculture Regulations & Compliance

The South Korean agricultural market is currently undergoing a significant transformation driven by the "Smart Farm" initiative and the need to address an aging farming population. The Ministry of Agriculture, Food and Rural Affairs (MAFRA) has implemented strict guidelines regarding the mechanization of upland and paddy farming. Specifically, there is a strong regulatory push towards converting rice paddies to dry field crops (like forage corn) to balance rice supply and demand. This creates a specific demand for versatile machinery like the 9YG-1.0, which can handle both rice straw (for bedding) and corn silage (for feed) without requiring complex modifications.

In terms of environmental regulations, South Korea enforces stringent emissions standards for agricultural machinery, aligning with Tier 4 and upcoming Tier 5 standards. While the 9YG-1.0 is an implement, it is designed to operate efficiently with modern, eco-friendly tractors commonly used in Korea (such as LS, Tong Yang, or Daedong), optimizing fuel consumption through its low-torque requirement design. Furthermore, local regulations regarding road transport of agricultural machinery are strict about width and visibility. The 9YG-1.0's transport width of 2300mm fits well within the standard rural road limits in provinces like Jeollanam-do and Gyeongsangbuk-do, ensuring legal compliance during transit between fragmented plots. EVER-POWER ensures that all safety lighting and reflective markings meet international ISO standards, which are compatible with Korean safety requirements.

6. Global & Regional Trend Analysis

The global trend in forage harvesting is shifting towards "High Density, Small Size" to accommodate smaller herd sizes and boutique livestock operations, a trend clearly mirrored in Japan and South Korea. There is a growing preference for Net Wrap over Twine due to the 30% reduction in binding time and better leaf retention, which preserves protein content in alfalfa and silage. The 9YG-1.0 is positioned perfectly at this intersection, offering commercial-grade density in a compact form factor. Additionally, the ability to harvest standing stalks (direct cut and bale) is becoming a sought-after feature to reduce field passes and soil compaction—a critical factor in sustainable soil management practices.

7. Equipment Compatibility & Replacement Guide

| Tractor Brand (Korea/Global) | Horsepower Req. | Тип сцепного устройства | PTO Spline | EVER-POWER Status |

|---|---|---|---|---|

| LS Mtron (Series U/X) | 65HP - 100HP | Drawbar / 2-Point | 6-Spline, 540/720 RPM | Fully Compatible |

| TYM (Tong Yang) | 70HP+ | Drawbar | Standard 1-3/8" Z6 | Fully Compatible |

| Daedong (Kioti) | RX Series | Drawbar | Standard | Fully Compatible |

| Kubota / Yanmar (Equiv.) | M Series | Drawbar | Standard | High-Value Replacement |

*Примечание: Указанные выше торговые марки приведены исключительно в иллюстративных целях. Мы не предлагаем оригинальную продукцию или оборудование под этими торговыми марками.

8. EVER-POWER Factory Capabilities & Customization

At EVER-POWER, we are not just assemblers; we are creators of agricultural innovation. Our manufacturing facility spans over 32,000 square meters and is equipped with advanced CNC laser cutting machines, automatic welding lines, and electrostatic powder coating systems. We hold ISO9001 certification and have been recognized as a National High-Tech Enterprise.

We understand that farming conditions vary globally. Therefore, we offer deep customization services (OEM/ODM) for our South Korean and international partners.

Whether you require specific color schemes to match your fleet,

reinforced pickup teeth for rocky terrain,

or modifications to the hydraulic interface to suit specific tractor hydraulics.

Our R&D center is ready to adapt the 9YG-1.0 to your exact needs. We inspect every unit through a rigorous quality control process before shipment to ensure zero defects upon arrival.

9. Customer Success Story

"We’ve been using the 9YG-1.0 Round Baler for our corn and wheat straw. The pickup width is impressive, and it handles the dense crops without any trouble. The machine’s high productivity has significantly reduced the time spent in the field, allowing us to focus on other tasks. Highly recommend!"

— Jin Ho Park, South Korea

"We run a mixed farm, and the 9YG-1.0 has made life so much easier. Whether it's corn stalks, grass, or alfalfa, this baler handles them all. It's a one-stop solution for all our baling needs, and the net wrap system has been fantastic for silage."

— Marco Alvarez, Spain

"The 9YG-1.0 has been part of our farming operations for over a year now, and we couldn’t be happier. It’s built tough and performs well under harsh conditions. The bale density is great for storage and transport, and the machine has had zero downtime."

— John Harris, USA

"As a small-scale farmer, I was looking for a cost-effective baler, and the 9YG-1.0 exceeded my expectations. It’s compact, easy to use, and gets the job done efficiently. Plus, it’s easy to maintain. Definitely a great investment for small farms."

— Min Ji, South Korea

"The 9YG-1.0 has saved us so much time on the field. It’s easy to operate, and we’ve seen a significant reduction in the number of field passes. Plus, the bales come out perfectly packed and tightly wrapped for easy handling and storage."

— James Middleton, Australia

10. Сопутствующие товары

10.1 Коробка передач:

Совместимые модели: EP-FK263 (квадратный пресс-подборщик), серия EP-RC30 (круглый пресс-подборщик, передаточное число 1:2, совместим с 35-мм 6-шлицевым валом).Применение: Передает мощность ВОМ на механизм прессования тюков, подходит для New Holland 630 или John Deere 535. Параметры: Крутящий момент > 500 Нм, экономия топлива 20%.Почему стоит выбрать именно этот редуктор: регулируемый размер (уменьшается до 250-300 мм), устойчивость к вязким загрязнениям (резиновым испарениям), степень защиты IP65. Вал отбора мощности:Совместимые модели: серия EP-PTO (шлицы Z6 1-3/8 дюйма, регулируемая длина 600-1200 мм).Применение: Соединяет трактор с главным приводом пресс-подборщика, подходит для типа 9YG-1.0C. КПД передачи крутящего момента >95%, совместим с фланцами SAE/EURO.Почему он подходит: Водонепроницаемая конструкция, подходит для работы с влажным силосом; может быть заменен на аналогичные модели серии Weasler.

10.2 Цепи & Зубчатые колеса:

Совместимые модели: ANSI #50/#60 цепис EP-звездочкой (шаг 12,7-19,05 мм, диаметр ролика 10-12 мм).Применение: Используется в конвейерных лентах или обвязочных механизмах, подходит для транспортировки соломы в квадратных/круглых тюках. Ширина 25-40 мм, износостойкая сталь.Почему это подходит: Совместимо с оборудованием Kobelco или HF Group, снижает риск обрыва цепи; доступен вариант пищевого качества для силоса.

10.3 Соединения:

Совместимые модели: муфты EP-Coupling серии 200 (согласование крутящего момента 500-1000 Нм).Применение: Соединяет редуктор с прессовальным роликом, гасит вибрацию.Почему это подходит: Высокая износостойкость, совместимость с Bondioli и Pavesi.

10.4 Гидравлический цилиндр:

Гидравлический цилиндр: Серия EP-HC (диаметр цилиндра 50-100 мм, ход поршня 300-600 мм), подходит для подъема тюков.Подшипники и уплотнения: подшипники 6208-2RS, ресурс L10 >10000 часов, пылезащитное уплотнение.Таблица совместимости: Полностью взаимозаменяема с Comer 250T (совпадение крутящего момента, цена всего 35%); фланец соответствует североамериканской схеме крепления ВОМ с 4 болтами.* Примечание: Указанные выше торговые марки приведены исключительно в иллюстративных целях. Мы не предлагаем оригинальную продукцию или оборудование, выпускаемые под этими торговыми марками.* Параметры могут различаться в зависимости от условий эксплуатации; пожалуйста, сверяйтесь с фактическими чертежами. Рекомендуется подтвердить размеры интерфейса перед выбором.

11. Часто задаваемые вопросы (FAQ)

Q1. What is the estimated landed cost or price for the 9YG-1.0 baler delivered to Incheon port, South Korea?

A1. The price varies based on order quantity and customization. We offer competitive factory-direct pricing (EXW, FOB, or CIF Incheon). Please contact our sales team for a detailed quote in USD or your preferred currency.

Q2. Can this round baler handle wet rice straw commonly found in Korean paddy fields without clogging?

A2. Yes, absolutely. The 9YG-1.0 features our exclusive "Axial Flow" feeding mechanism and no-cam pickup, which are specifically engineered to handle high-moisture crops like wet rice straw without the blockages common in traditional machines.

Q3. Which local Korean tractor brands are compatible with the PTO and hydraulic requirements of this baler?

A3. The 9YG-1.0 is compatible with major Korean brands like LS, TYM, Branson, and Daedong (Kioti) tractors ranging from 48kW to 80kW. It uses a standard 540/720 RPM PTO and standard hydraulic couplings.

Q4. How does the net wrapping system compare to twine tying for silage production in humid climates?

A4. Net wrapping is superior for silage. It covers the bale surface faster (increasing productivity) and holds the material tighter, reducing oxygen pockets. This leads to better fermentation and less spoilage in humid climates.

Q5. Where can I find replacement parts like pickup tines or rollers if they break during harvest season?

A5. EVER-POWER maintains a robust supply chain. We can ship spare parts via air freight for urgent needs. Additionally, we provide a recommended spare parts kit with every machine purchase to minimize downtime.

Q6. What is the recommended maintenance schedule for the roller bearings and chain drive system?

A6. We recommend checking chain tension and lubricating main bearings every 8-10 hours of operation. Since our design lacks a cam track, daily maintenance is significantly faster and simpler than competitor models.

Q7. Can this machine be customized to harvest standing corn stalks directly without pre-cutting?

A7. Yes, the 9YG-1.0 is robust enough to handle standing corn stalks. However, for optimized operation, we can customize the pickup with specialized hammer-claw modifications upon request for specific crop conditions.

Q8. How does the bale density of the 9YG-1.0 compare to Japanese brands like Takakita or Star?

A8. The 9YG-1.0 offers comparable or superior density (up to 200kg/m³) due to its heavy-duty 16-roller compression chamber, while offering a much more attractive price-to-performance ratio than Japanese alternatives.

Q9. What are the specific dimensions for shipping, and how many units fit in a 40HQ container?

A9. The working dimensions are 3750×2300×2020 mm. For shipping, we can optimize the packing. Please contact us for a precise loading plan to maximize the number of units in a 40HQ container.

Q10. Does EVER-POWER provide technical support or manuals in English or Korean for installation?

A10. Yes, we provide comprehensive manuals in English and can offer video installation guides. We are committed to supporting our global partners with the technical documentation needed for smooth operation.

Готовы повысить эффективность сбора урожая?

Contact EVER-POWER today for the best prices on the 9YG-1.0 Mini Round Baler.

Company Name: EVER-POWER Agricultural Balers CO., LTD.

Email: [email protected]

Редактор: PXY