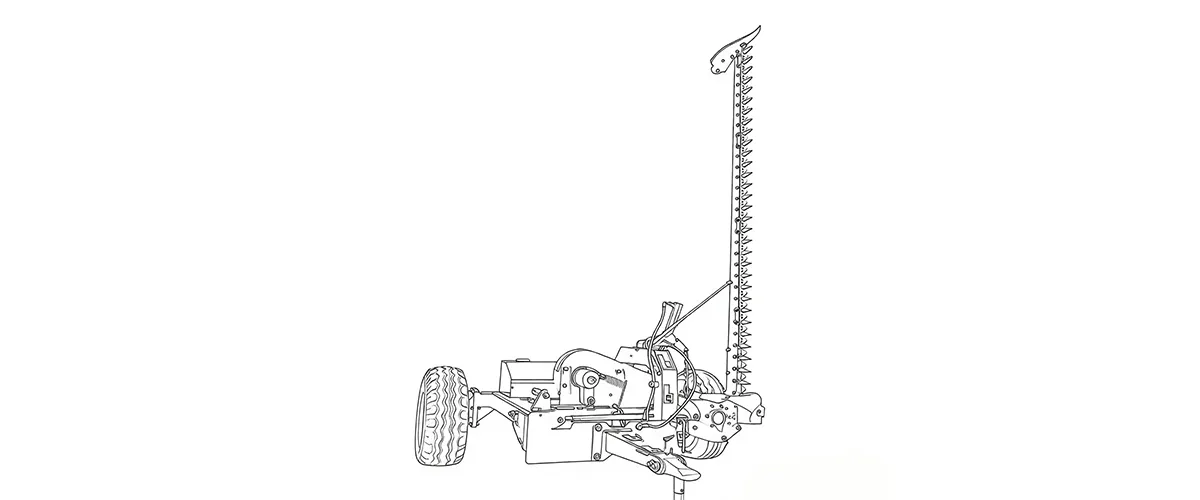

Descrição

1. Technical Specifications & Parameters

| Não. | Item | Unidade | Especificação |

|---|---|---|---|

| 1 | Nome do modelo | / | 9GD-2.5 Trailed Single Blade Mower Upgraded version |

| 2 | Tipo de engate | / | Seguido |

| 3 | Tipo de estrutura de corte | / | Reciprocante |

| 4 | Largura de corte | m | 2.5 |

| 5 | Matching Power Range | kw | 15-35 |

| 6 | Faixa de velocidade de trabalho | km/h | 6-10 |

| 7 | Número de lâminas móveis | peças | 34 |

| 8 | Dimensions (Length × Width × Height) | mm | 2000×4300×950 |

| 10 | Power Output Shaft Speed | r/min | 540 |

| 11 | Altura média de corte | mm | 50-70 |

| 12 | Produtividade | hm2/h | 2.0-3.0 |

| 13 | Number of Operators | (persons) | 1 |

| 14 | Structure Weight | kg | 490 |

2. Advanced Cutting Technology & Application Scenarios

3. Global Regulatory Standards & Compliance

4. Market Trend Analysis: The Future of Forage Harvesting

The global agricultural sector is witnessing a significant shift towards “precision harvesting.” In South Korea, where the aging rural population is creating a labor shortage, there is an increasing demand for machinery that offers high hectares-per-hour (ha/h) efficiency with minimal maintenance. The 9GD-2.5 Towed Single-Blade Lawn Mower for sale caters to this trend by providing a “set and forget” mechanical reliability. We are also seeing a movement towards offset mowers that minimize soil compaction by keeping the tractor on already-cut paths. Industry data suggests that the market for sickle-bar mowers is projected to grow by 4.2% annually as farmers recognize the superior dry-down speed of reciprocating-cut forage compared to rotary-cut crops.

5. Component Compatibility & Brand Comparison

| Brand/Component | Compatibility Status | Key Benefit for Korean Market |

|---|---|---|

| LS Mtron / Daedong Tractors | Fully Compatible | Direct fit for standard Category 1 & 2 hitches. |

| Jiujia 65Mn Blades | OEM Standard | Higher wear resistance than generic carbon steel. |

| Walterscheid PTO Shafts | Compatible | Enhanced safety with world-class torque protection. |

| SKF / NSK Bearings | Standardized | Easy local procurement for maintenance in Korea. |

6. Customer Success Case Study:

Client 1 Profile: South Korea, Gyeonggi-do Forage Producer

Customer Reviews:

“As a commercial forage producer in Gyeonggi-do, I rely on the 9GD-2.5 Towed Mower to maintain my alfalfa fields. The 3.2-meter cutting width means I can get through large fields quickly, which is critical during the short harvest windows. The adjustable rollers ensure that I can condition my crops perfectly, even in the wet, dense fields we have here. The machine has definitely saved us time and improved our hay quality, leading to better prices at the market.”

Client 2 Profile: United States, Midwest Alfalfa Farmer

Customer Reviews:

“Here in the Midwest, where the weather can be unpredictable, the 9GD-2.5 Mower is a game-changer. The adjustable conditioning rollers are fantastic for getting the perfect drying conditions, and the sturdy frame handles our rocky soils well. We’ve seen a 30% reduction in drying time compared to other mowers we’ve used in the past, which has greatly improved our overall productivity.”

Client 3 Profile: Australia, Queensland Livestock Farmer

Customer Reviews:

“In Queensland, we deal with a lot of heavy clay and uneven terrain. The 9GD-2.5 Mower’s towed design provides superior stability compared to mounted models. This makes it much easier to navigate the slopes and still get a uniform cut. The 540 RPM PTO works perfectly with my tractor, and I’ve been impressed with how the mower handles our challenging conditions without compromising on performance.”

Client 4 Profile: Brazil, São Paulo Forage Grower

Customer Reviews:

“We’ve been using the 9GD-2.5 Mower for over a year now on our large-scale forage operation in São Paulo. The machine’s high cutting width and robust construction make it perfect for our humid conditions, and it handles our tall grasses and dense crops with ease. The 65Mn manganese steel blades last much longer than the standard carbon steel blades we used to have, and the increased productivity has really helped us keep up with demand.”

7. EVER-POWER Factory: Customization & Quality Assurance

Localizada na Zona de Desenvolvimento Econômico e Tecnológico de Hulunbuir, nossa unidade fabril abrange mais de 32.000 metros quadrados Nossa fábrica está equipada com máquinas de corte a laser CNC de última geração, linhas de soldagem automática e linhas de pintura eletrostática a pó. Não somos apenas uma montadora; somos uma fabricante completa com ampla capacidade de pesquisa e desenvolvimento.

Serviços de personalização (OEM/ODM): Entendemos que as condições agrícolas variam de região para região. Para o mercado sul-coreano, oferecemos opções de personalização, incluindo:

• Adaptação hidráulica: Ajuste das pressões das válvulas para corresponder aos fluxos hidráulicos específicos dos tratores LS ou Daedong.

• Melhorias nos pneus: Pneus de flutuação mais largos opcionais para arrozais com lama profunda.

• Cor e identidade visual: Serviços de personalização de marca para revendedores e distribuidores (OEM).

Nós mantemos Certificação do Sistema de Gestão da Qualidade ISO 9001 e foram reconhecidas como uma Empresa Nacional de Alta Tecnologia. Cada enfardadeira 9YG-2.24D passa por um rigoroso teste de operação contínua de 48 horas antes do envio para garantir zero defeitos na chegada.

8. Related products

8.1 Gearbox:

Modelos compatíveis: EP-FK263 (enfardadeira de fardos quadrados), série EP-RC30 (enfardadeira de fardos redondos, relação de transmissão 1:2, compatível com eixo de 35 mm com 6 estrias).Aplicação: Transmite a potência da tomada de força (TDF) para o mecanismo de enfardamento, adequado para New Holland 630 ou John Deere 535. Parâmetros: Torque > 500 Nm, economia de combustível 20%.Por que escolher esta caixa de engrenagens: Tamanho personalizável (reduzível para 250-300 mm), resistente a contaminantes viscosos (vapores de borracha), proteção IP65. Eixo da tomada de força:Modelos compatíveis: Série EP-PTO (estria Z6 de 1-3/8″, comprimento ajustável de 600 a 1200 mm).Aplicação: Conecta o trator à transmissão principal da enfardadeira, adequado para o tipo 9YG-1.0C. Eficiência de transmissão de torque >95%, compatível com flanges SAE/EURO.Por que é adequado: Design à prova d'água, ideal para operações com silagem úmida; substituível pela série Weasler.

8.2 Correntes e rodas dentadas:

Modelos compatíveis: ANSI correntes, com roda dentada EP (passo de 12,7 a 19,05 mm, diâmetro do rolo de 10 a 12 mm).Aplicação: Utilizado em correias transportadoras ou mecanismos de amarração, adequado para o transporte de palha em enfardadeiras quadradas/redondas. Largura de 25 a 40 mm, material em aço resistente ao desgaste.Por que é adequado: Compatível com equipamentos Kobelco ou do Grupo HF, reduz o risco de quebra da corrente; opção de qualidade alimentar disponível para silagem.

8.3 Couplings:

Modelos compatíveis: Acoplamento EP série 200 (torque compatível de 500 a 1000 Nm).Aplicação: Conecta a caixa de engrenagens ao rolo enfardador, amortecendo a vibração.Por que é adequado: Alta durabilidade em ciclos de uso, compatível com Bondioli e Pavesi.

8.4 Cilindro hidráulico:

Cilindro hidráulico: Série EP-HC (diâmetro de 50 a 100 mm, curso de 300 a 600 mm), adequada para levantamento de fardos.Rolamentos e vedações: Rolamentos 6208-2RS, vida útil L10 > 10.000 horas, vedação à prova de poeira.Tabela de compatibilidade: Totalmente intercambiável com Comer 250T (torque compatível, apenas 35% a menos no preço); flange compatível com o padrão de tomada de força (PTO) de 4 parafusos da América do Norte.* Aviso: As outras marcas mencionadas acima são fornecidas apenas para fins ilustrativos. Não oferecemos produtos ou equipamentos originais com essas marcas.* Os parâmetros variam dependendo das condições de trabalho; consulte os desenhos reais. Recomenda-se confirmar as dimensões da interface antes da seleção.

9. Agricultural Professional FAQ

Q1. How much does a professional 9GD-2.5 Towed Single-Blade Lawn Mower cost for farms in Gyeonggi-do?

A1. The **price** of the 9GD-2.5 depends on specific customization and shipping logistics to Busan or Incheon. Generally, as a factory-direct **supplier**, we offer the most competitive commercial **quotes** for high-volume orders in South Korea.

Q2. Where can I find a reliable Jiujia machinery supplier for agricultural mower parts near Seoul?

A2. Jiujia provides a direct distribution network across Korea. You can contact our **Jiujia machinery Korea** service center or request a local **supplier** list via our website to ensure you receive genuine parts and professional maintenance.

Q3. What is the recommended engine power needed to operate the towed single-blade mower efficiently in heavy grass?

A3. For the 9GD-2.5 model, we recommend a tractor with at least 20 HP. However, for dense or wet forage common in the Gangwon-do highlands, a 40-50 HP tractor will provide the reserve torque required for a consistent cutting speed.

Q4. How does the reciprocating blade technology help with high-yield alfalfa harvesting compared to standard rotary cutters?

A4. Reciprocating mowers like our **Jiujia mower** provide a clean shear cut. This prevents the “bruising” and leaf loss associated with rotary slashers, resulting in higher nutritional value and faster regrowth of the alfalfa crop.

Q5. Which type of maintenance is required for the 9GD-2.5 Towed Single-Blade Lawn Mower during the harvest season?

A5. Maintenance is straightforward: ensure the sickle bar is lubricated daily, check the blade sharpness every 50 hours of operation, and verify that the safety trip mechanism is clear of debris. Most parts are standardized for quick replacement.

Q6. Why should professional land cooperatives in Korea choose Jiujia as their primary agricultural mower manufacturer?

A6. Jiujia is a specialized **manufacturer** with 20+ years of history. We offer upgraded editions with reinforced frames and 65Mn manganese steel blades, specifically designed to withstand the rocky and demanding soil conditions found in South Korea.

Q7. How does the machine handle rocky terrain or hidden obstacles during high-speed field operations?

A7. The 9GD-2.5 (Upgraded Edition) features an automatic safety trip mechanism. If the blade hits a significant obstacle, the bar will swing back instantly, preventing structural damage to the frame or the tractor’s PTO shaft.

Q8. When is the best time to replace the manganese steel blades on a used Jiujia machinery mower?

A8. Blades should be replaced when they show signs of excessive thinning or if they cannot be sharpened back to a clean edge. Using original Jiujia blades ensures perfect balance and prevents vibration damage to the crank-link system.

Q9. What are the shipping logistics for importing agricultural machinery from Jiujia to the South Korean port of Busan?

A9. We offer comprehensive EXW, FOB, and CIF shipping terms. Most orders for the 9GD-2.5 series are containerized and shipped directly to Busan or Incheon, with full documentation provided for local customs clearance and tax benefits.

Q10. How do I adjust the cutting height of the 9GD-2.5 mower for different crop types?

A10. The cutting height is easily adjustable via the mechanical slide shoes located at each end of the sickle bar. By changing the shoe angle, you can set the cut from as low as 3cm for lawns to 8cm for tall forage.

Editor: PXY

*Aviso: As outras marcas mencionadas acima são fornecidas apenas para fins ilustrativos. Não oferecemos produtos ou equipamentos originais com essas marcas.