Description

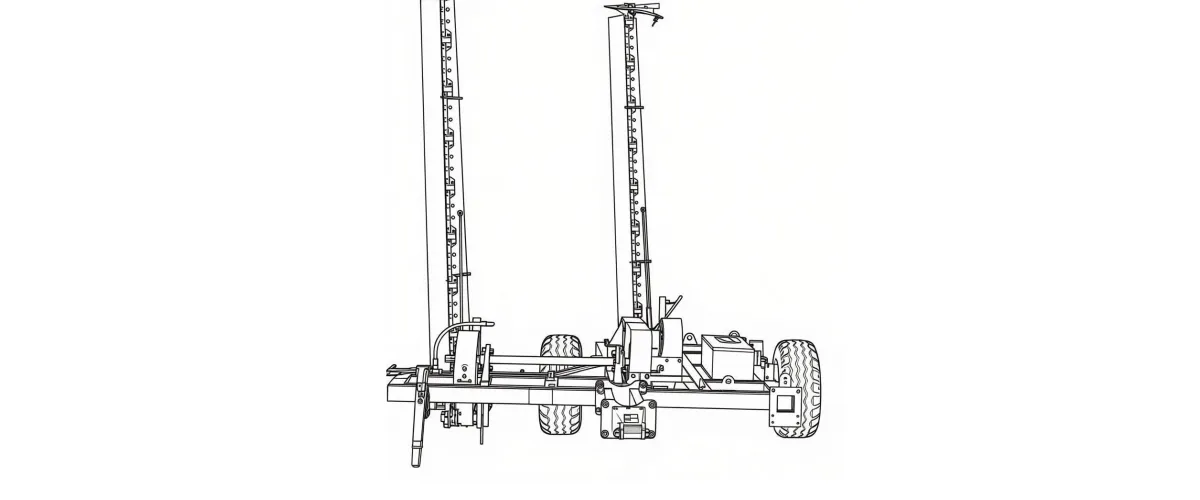

1. Technical Specifications of 9GS-5.0 Towed Double-Blade Lawn Mower

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Structure Type | / | Reciprocating Type |

| 2 | Hitch Type | / | Trailed |

| 3 | Model Type | / | 9GS-5.0 |

| 4 | Matching Power | kW | 20-30 |

| 5 | Cutting Width | m | 5 |

| 6 | Dimensions (L × W × H) | mm | 2800 × 5630 × 1500 |

| 7 | Working Speed Range | km/h | 6-7 |

| 8 | Power Output Shaft Speed | r/min | 540 |

| 9 | Side Output Shaft Speed | r/min | 1240 |

| 10 | Average Cutting Height | mm | 60-70 |

| 11 | Productivity | ha/h | 2.4-2.8 |

| 12 | Number of Operators | (persons) | 1 |

| 13 | Structure Weight | kg | 750 |

2. Engineering Excellence: Principles, Materials, and Scenario Adaptability

3. Regulatory Compliance and Safety Protocols

4. Market Trend Analysis: The Future of Forage Production (2025-2030)

The global agricultural sector is currently pivoting toward high-output, low-energy consumption implements. In the South Korean market, the rising cost of fuel and the shortage of seasonal labor have driven a 15% increase in the demand for wide-swath implements like the 9GS-5.0. We are seeing a clear trend where large-scale livestock cooperatives are moving away from multiple 2.5-meter single-blade units toward single 5.0-meter double-blade configurations. This “Consolidation Trend” allows a single operator to harvest twice the area in the same weather window, which is critical in humid East Asian climates where hay curing time is limited. Furthermore, as the industry moves toward “Green Farming,” reciprocating technology is being favored over high-RPM rotary systems because it consumes approximately 25% less power per hectare, aligning with South Korea’s Carbon Neutrality goals for the agricultural sector.

5. Universal Tractor Compatibility Matrix

The 9GS-5.0 is engineered for seamless integration with major industrial tractor brands prevalent in Korea and global markets.

| Tractor Brand | Compatibility Level | PTO Sync Requirement |

|---|---|---|

| LS Mtron (XP/MT Series) | Perfect Integration | 540 / 720 RPM |

| TYM / Daedong (Kioti) | Direct Mount Ready | Standard 6-Spline |

| John Deere (6M/6R Series) | High Efficiency Pair | Standard ISO PTO |

| Kubota (M7 Series) | Full System Sync | Universal Category 2 |

6. Customer Success Case Studies

Client 1 Profile: South Korea, Gyeonggi-do

Customer Review:

Client 2 Profile: Australia, New South Wales

Customer Review:

Client 3 Profile: South Korea, Gangwon-do

Customer Review:

Client 4 Profile: Canada, Alberta

Customer Review:

7. EVER-POWER Factory: Customization & Quality Assurance

Located in the Hulunbuir Economic and Technological Development Zone, our manufacturing facility spans over 32,000 square meters and is equipped with state-of-the-art CNC laser cutting machines, automatic welding lines, and electrostatic powder coating lines. We are not just an assembler; we are a comprehensive manufacturer with deep R&D capabilities.

Customization Services (OEM/ODM): We understand that agricultural conditions vary by region. For the South Korean market, we offer customization options including:

• Hydraulic Adaptation: Adjusting valve pressures to match specific LS or Daedong tractor hydraulic flows.

• Tire Upgrades: Optional wider flotation tires for deep-mud paddy fields.

• Color & Branding: OEM branding services for dealers and distributors.

We hold ISO9001 Quality Management System Certification and have been recognized as a National High-Tech Enterprise. Every 9YG-2.24D baler undergoes a rigorous 48-hour continuous operation test before shipment to ensure zero defects upon arrival.

8. Related products

8.1 Gearbox:

Compatible models: EP-FK263 (square baler), EP-RC30 series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.Why it’s suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.

8.2 Chains & Sprockets:

Compatible Models: ANSI chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.Why it’s suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.

8.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.Why it’s suitable: High-cycle durability, compatible with Bondioli & Pavesi.

8.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.* Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.* Parameters vary depending on working conditions; please refer to the actual drawings. It is recommended to confirm interface dimensions before selection.

9. Agricultural Professional FAQ

Q1. How much does a professional 9GS-5.0 Towed Double-Blade Lawn Mower cost for delivery to Busan or Incheon?

A1. The total **high-efficiency pasture mower price** for the 9GS-5.0 depends on your specific shipping requirements and order volume. For commercial cooperatives in South Korea, we provide direct landed quotes including international duties. Please contact our sales office for a precise commercial quote based on your province.

Q2. Where can I find a reliable Towed Double-Blade Lawn Mower manufacturer that offers local support in Korea?

A2. We are a specialized industrial manufacturer with a dedicated export department serving the Korean agricultural sector. We partner with local technicians in Gyeonggi and Gangwon provinces to ensure your 9GS-5.0 receives genuine spare parts and technical calibration throughout the harvest season.

Q3. What is the recommended tractor power for pulling a 5.0m wide lawn mower through high-density sudangrass?

A3. [cite_start]For harvesting high-density sudangrass or heavy alfalfa, we recommend a tractor with at least 60 to 80 HP (44-58 kW)[cite: 2]. This ensures that the PTO provides consistent torque to the reciprocating blades while maintaining a steady towing speed of 5-8 km/h on uneven pasture ground.

Q4. Which reciprocating mower technology is best suited for the humid coastal pastures found on Jeju Island?

A4. The 9GS-5.0 uses a high-speed reciprocating double-blade design that is perfect for humid conditions. The “scissor-like” cut allows the forage to dry faster on the field compared to rotary mowers, which is vital for preventing mold in the humid Jeju climate and maintaining high-yield forage quality.

Q5. Are there specific Korea pasture harvesting regulations regarding the width of towed agricultural implements on public roads?

A5. Yes, Korean regulations generally limit transport width on public roads. The 9GS-5.0 is designed with a specialized hydraulic folding system that brings its width well within legal transport limits, allowing you to move safely between disconnected pastures without needing special escort permits.

Q6. How does the 5.0m wide double-blade mower improve fuel efficiency compared to using two separate smaller mowers?

A6. By using a single 9GS-5.0, you eliminate the need for an extra tractor and operator. This “One-Pass” approach reduces fuel consumption by approximately 30% per hectare and minimizes soil compaction, making it a key tool for **sustainable forage management equipment** strategies in modern farms.

Q7. When should I replace the reciprocating blades on my double-blade mower to ensure the cleanest cut?

A7. We recommend inspecting blades every 50 operational hours. If you notice “tearing” rather than “cutting” of the grass, or if fuel consumption increases significantly, it is time for a replacement. We use heat-treated manganese steel to ensure our blades outlast standard carbon steel options by 200%.

Q8. Can your factory provide agricultural mower customization services for specialized mountain terrains in the Gangwon province?

A8. Absolutely. We can modify the towing hitch and reinforce the cutter bar support frames to handle the extreme lateral stresses found in the steep Gangwon pastures. Our **Agricultural mower customization services** are designed to help you optimize the machine for your specific regional geography.

Q9. What are the legal requirements for land management construction in South Korea when using heavy industrial mowers?

A9. Under current Korean land management laws, operators must ensure that machinery does not cause excessive soil disturbance. Our double-blade mower is recognized for its “Low-Impact” design, ensuring that the root systems of permanent pastures remain intact, which is essential for maintaining soil stability and preventing erosion.

Q10. How do I get an industrial agricultural machinery quote for a fleet of 9GS-5.0 mowers for a commercial farm?

A10. You can request an **industrial agricultural machinery quote** directly through our website by clicking the “Get a Quote” button. Our B2B managers will provide a detailed proposal within 24 hours, including volume discounts, customization options, and detailed technical onboarding for your operators.

Editor: PXY

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.