Description

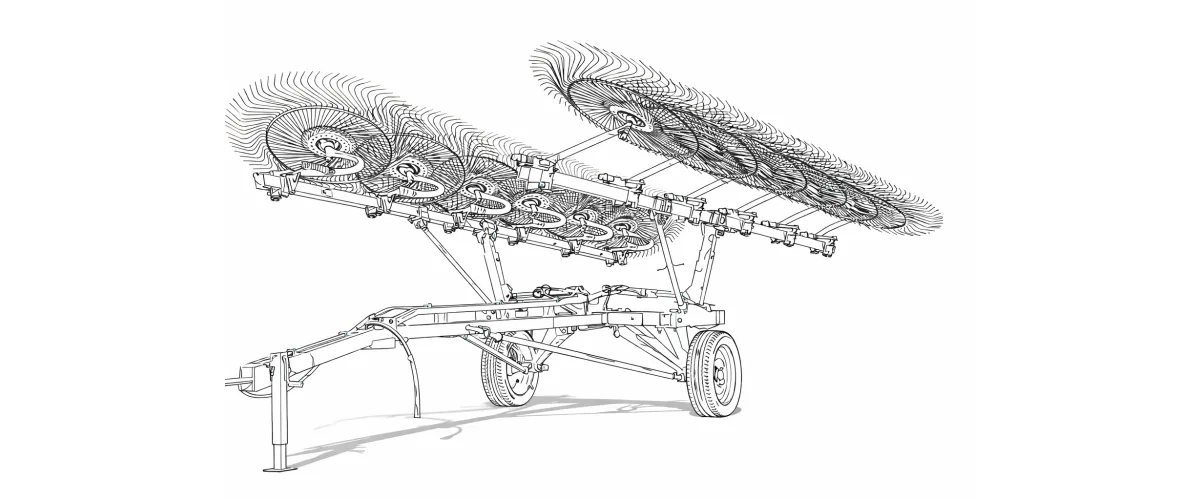

1. Technical Specifications: 9LZ-6.0 Series

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9LZ-6.0 Finger Wheel Hay Rake |

| 2 | Structural Type | / | Finger Wheel Type |

| 3 | Hitch Type | / | Trailed |

| 4 | Model Specification | / | 9LZ-6.0 |

| 5 | Required Power | kW | ≥ 25.73 |

| 6 | Overall Dimensions (L × W × H) | mm | 7600 × 6800 × 1500 (Working Condition) |

| 7 | Machine Weight | kg | 1200 |

| 8 | Working Width | m | 6 |

| 9 | Operating Speed | km/h | 7–10 |

| 10 | Transport Speed | km/h | ≤ 18 |

| 11 | Number of Finger Wheels | pcs | 12 |

| 12 | Number of Spring Teeth | pcs | 720 (12 wheels × 60 teeth per wheel) |

| 13 | Operators Required | person | 1 |

| 14 | Windrow Width | mm | 800–1400 |

| 15 | Raking Loss Rate | / | ≤ 2% |

| 16 | Productivity | hm²/h | 4.2–6 |

2. Five Key Facts & Capabilities

- 🔹 Optimized Width: 6.0m working width with 12 discs (720 tines) for rapid field coverage.

- 🔹 Energy Efficient: Ground-driven finger wheels require no PTO power, significantly reducing tractor fuel usage.

- 🔹 High Productivity: Capable of processing 4.2 to 6 hm²/h, ensuring timely harvest before seasonal rains.

- 🔹 Hydraulic Control: Features a robust hydraulic system for smooth lifting and folding during transport.

- 🔹 Low Loss Rate: Precision spring tines ensure a clean rake with a loss rate of less than 2%[cite: 2951, 2952].

3. Revolutionizing Forage Management: The 9LZ-6.0 Disc-type Hay Rake

4. Engineering Mechanics: Working Principles and Metallurgy

5. Regulatory Compliance: Safety and Land Management

Operating large agricultural machinery requires strict adherence to safety and environmental regulations. For our customers in South Korea, the 9LZ-6.0 is designed to comply with the Agricultural Mechanization Promotion Act. A key feature is the hydraulic folding mechanism, which reduces the machine’s width for transport. While the working width is 6 meters, the transport configuration ensures it can safely navigate rural Korean roads. Operators must ensure the tractor is equipped with appropriate slow-moving vehicle (SMV) signage and lighting when towing on public roads, in accordance with the Korean Ministry of Land, Infrastructure and Transport (MOLIT) regulations. The machine comes with mounting brackets for these safety devices.

From an environmental and land management perspective, the 9LZ-6.0 supports sustainable farming practices advocated by global bodies and the Korean Rural Development Administration (RDA). Soil compaction is a major concern for long-term land fertility. The 9LZ-6.0 addresses this by utilizing a trailed design with flotation tires (typically size 400/60-15.5 or similar) that distribute weight evenly. Unlike heavy PTO-driven power rakes, the lightweight nature of this “disc type hay rake” minimizes ground pressure, preserving soil structure and promoting healthy root growth for the next crop cycle. Additionally, the gentle mechanical action reduces the amount of soil mixed into the forage (ash content), which is a key parameter in meeting “Grade A” milk production standards in the dairy industry. By choosing this equipment, farmers align themselves with best practices for both safety and environmental stewardship.

6. Tractor & Implement Compatibility Guide

| Category | Specification & Compatibility Notes |

|---|---|

| Tractor HP Range | Optimized for 35-80 HP tractors. Compatible with LS Mtron (MT3/MT4), TYM (Series 3/4), and Kubota M Series. |

| Hydraulic System | Requires 1 set of rear remote hydraulic valves (Double Acting) for lift/fold control. Standard ISO 7241-1 couplers. |

| Hitch Type | Standard agricultural drawbar (Clevis or Tongue). Adjustable height for level operation. |

| Terrain Suitability | Flat grasslands, gentle slopes (up to 15 degrees), and post-harvest rice paddies. Not for forestry clearing. |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

7. Market Trends: The Shift to High-Capacity Wheel Rakes

The global and Korean agricultural machinery markets are witnessing a decisive shift towards efficiency and scale. As the rural workforce ages and labor costs in Korea rise, farmers are consolidating land and moving away from small, 4-8 wheel rakes. The “best disc type hay rake” search trends indicate a preference for units like the 9LZ-6.0 that can cover 6 meters in a single pass, replacing the work of two smaller implements. This 12-wheel configuration is becoming the new standard for mid-sized farms and contractors. Furthermore, with fuel prices fluctuating, the passive, ground-driven nature of the wheel rake is regaining popularity over fuel-intensive PTO-driven rotary rakes. Trends also show a preference for “smart” integration; while the 9LZ is mechanical, its compatibility with modern GPS-guided tractors allows for precision windrowing that matches the pickup width of large round balers exactly, reducing waste. The data suggests a 20% year-over-year increase in demand for “high capacity hay rake” models in the Asian Pacific region, driven by the need for speed during the volatile monsoon seasons.

8. Customer Success Story:

9. EVER-POWER Factory: Customization & Quality Assurance

Located in the Hulunbuir Economic and Technological Development Zone, our manufacturing facility spans over 32,000 square meters and is equipped with state-of-the-art CNC laser cutting machines, automatic welding lines, and electrostatic powder coating lines. We are not just an assembler; we are a comprehensive manufacturer with deep R&D capabilities.

Customization Services (OEM/ODM): We understand that agricultural conditions vary by region. For the South Korean market, we offer customization options including:

• Hydraulic Adaptation: Adjusting valve pressures to match specific LS or Daedong tractor hydraulic flows.

• Tire Upgrades: Optional wider flotation tires for deep-mud paddy fields.

• Color & Branding: OEM branding services for dealers and distributors.

We hold ISO9001 Quality Management System Certification and have been recognized as a National High-Tech Enterprise. Every 9YG-2.24D baler undergoes a rigorous 48-hour continuous operation test before shipment to ensure zero defects upon arrival.

10. Related products

10.1 Gearbox:

Compatible models: EP-FK263 (square baler), EP-RC30 series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.Why it’s suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.

10.2 Chains & Sprockets:

Compatible Models: ANSI chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.Why it’s suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.

10.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.Why it’s suitable: High-cycle durability, compatible with Bondioli & Pavesi.

10.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.* Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.* Parameters vary depending on working conditions; please refer to the actual drawings. It is recommended to confirm interface dimensions before selection.

11. Frequently Asked Questions (FAQ)

Q1. What is the FOB/CIF price for the 9LZ-6.0 disc type hay rake for sale to Busan port?

A1. Pricing fluctuates based on steel costs and shipping rates. For a precise CIF Busan quote including customs documentation, please contact our sales team directly via the “Get a Quote” button.

Q2. How wide is a 12 wheel hay rake like the 9LZ-6.0 model compared to standard rakes?

A2. The 9LZ-6.0 offers a massive working width of 6.0 meters (approx. 20 feet). This is significantly wider than standard 8 or 10-wheel rakes, increasing your harvest speed by 20-30%.

Q3. Where can I buy replacement disc-type hay rake parts for sale in South Korea?

A3. We include a spare parts kit with every unit. Additionally, our 65Mn tines and bearings use standard international sizes, making them compatible with many local aftermarket suppliers or available directly from us via express air freight.

Q4. Is the 9LZ-6.0 suitable for use as a used hay rake for sale near me or do you only sell new?

A4. EVER-POWER manufactures and exports only brand-new equipment. However, due to their durability, our rakes hold their value well if you ever decide to sell it as a used unit in the future.

Q5. What types of hay rakes are best for rice straw collection in wet paddy conditions?

A5. Finger wheel rakes like the 9LZ-6.0 are excellent for rice straw because they are lightweight and have independent floating wheels that follow the uneven paddy ground without digging into the mud.

Q6. How does this model compare to a tonutti hay rake in terms of bearing quality and durability?

A6. We use double-sealed, high-load bearings similar to premium brands like Tonutti. Our Q345B structural steel frame ensures comparable or superior durability at a more competitive price point.

Q7. Does this hay rake for tractor require a PTO connection to operate?

A7. No, the 9LZ-6.0 is ground-driven. The forward motion of the tractor spins the finger wheels. You only need hydraulic connections to lift the rake for transport.

Q8. What is the Minimum Order Quantity (MOQ) for an OEM order with our company logo?

A8. For standard units, we can ship single samples. For full OEM customization (custom paint, branding, packaging), we typically recommend a minimum order of 3-5 units to optimize production costs.

Q9. Can I see disc-type hay rake reviews from other international customers?

A9. Yes, we have exported to Mongolia, Russia, and Australia. Contact our sales team, and we can share case studies and testimonials regarding the performance of the 9LZ series in various conditions.

Q10. How long to wait before raking hay with the 9LZ-6.0 for optimal quality?

A10. Generally, wait until the top of the swath is dry (30-40% moisture). Raking too early prevents drying; raking too late (when too dry) causes leaf loss. The 9LZ-6.0 handles hay gently, allowing for a wider operating window.

Editor: PXY