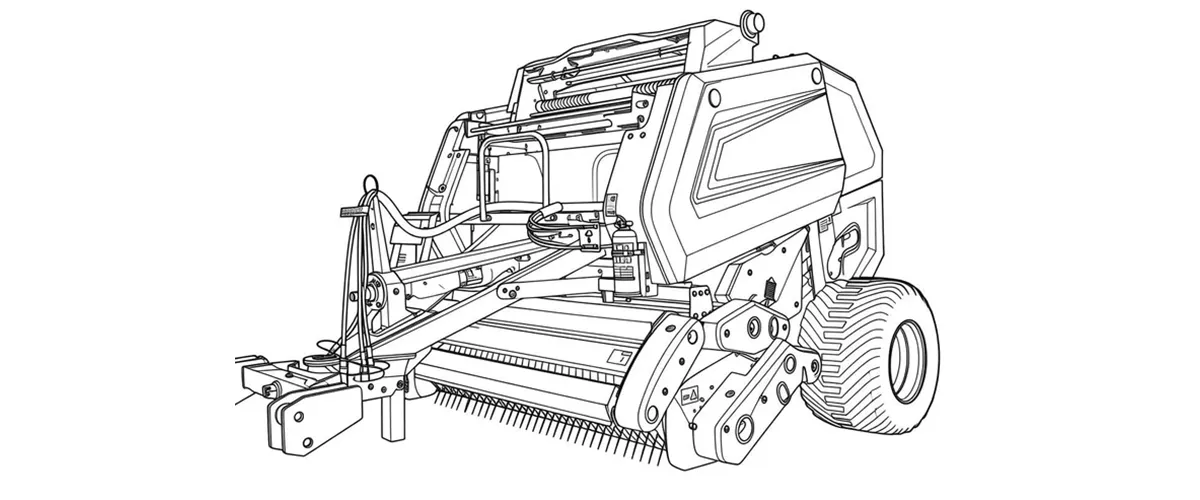

EP-9YG-1.25 Round baler

The 9YG-1.25 Round Baler is an engineered breakthrough featuring an interchangeable Hammer Claw Pickup system specifically designed for standing corn stalks, eliminating pre-shredding steps. Optimized for high-density compression (up to 200kg/m³), it serves as a critical asset for livestock feed management in high-demand markets like South Korea. This machine integrates seamlessly with 88kW+ tractors, offering automated net binding and robust durability for tough agricultural environments.

1. Technical Specifications of 9YG-1.25

| No. | Item | Unit | Specification1 | Specification2 |

|---|---|---|---|---|

| 1 | Model Name | / | 9YG-1.25 Round Baler | 9YG-1.25 Round Baler |

| 2 | Hitch Type | / | Trailed | Trailed |

| 3 | Pickup Width | mm | 2240 | 2240 |

| 4 | Pickup Structure Type | / | Ball Type and Spiral Pinch Type Convertible | Ball Type |

| 5 | Feeding Mechanism Structure | / | Feeding Rotor + Roller Type | Feeding Rotor + Roller Type |

| 6 | Compression Chamber Type | / | Roller Chamber | Roller Chamber |

| 7 | Compression Chamber Width | mm | 1250 | 1250 |

| 8 | Compression Chamber Diameter | mm | 1200 | 1200 |

| 9 | Number of Roller Working Components | pcs | 18 (rollers) | 18 (rollers) |

| 10 | Roller Diameter | mm | 222 | 222 |

| 11 | Baling Method | / | Automatic Net Wrap | Automatic Net Wrap |

| 12 | Required Power | kW/hp | ≥88.2 / 120 | ≥75 |

| 13 | Structural Weight | kg | 4558 | 4060 |

| 14 | PTO Output Shaft Speed | r/min | 720 | 720 |

| 15 | Dimensions (L × W × H) | mm | 5250 × 2700 × 2350 (working condition) | 4400 × 2850 × 2400 (working condition) |

| 16 | Forage Density Control | / | Sensor-Controlled | Sensor-Controlled |

| 17 | Bale Size (Diameter × Width) | mm | 1200 × 1250 | 1300 × 1250 |

| 18 | Bale Density | kg/m³ | 115–200 | 100–200 |

| 19 | Productivity | bale/h | 40–80 | 40–100 |

| 20 | Wheelbase | mm | 2450 | 2450 |

| 21 | Operating Speed | km/h | 5–20 | 5–35 |

| 22 | Net Wrap Specification | m | 2000 × 1.25 / roll | 2000 × 1.25 / roll |

| 23 | Number of Net Wraps | pcs | 18 |

2. Key Engineering Facts

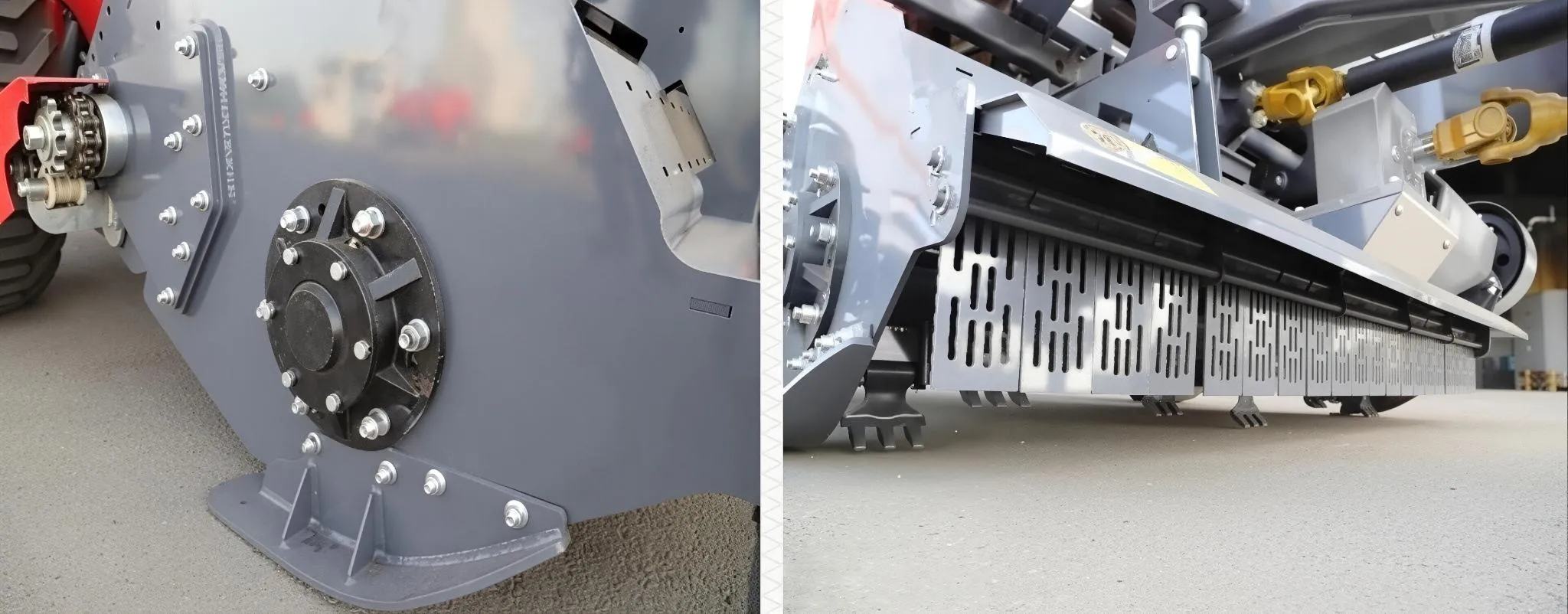

- Dual-Mode Pickup: Switch between Spring Tooth for grass and Hammer Claw for direct standing corn stalk harvesting.

- High Productivity: Capable of processing 40 to 80 bales per hour depending on crop conditions.

- Compression Tech: Uses 18 heavy-duty steel rollers to achieve bale densities between 115-200 kg/m³.

- Feeding System: Advanced Auger + Tine Roller + Drum combination prevents blockage in dense crop rows.

- Reliability: Manufactured by EVER-POWER (Jiujia), a National High-Tech Enterprise with ISO9001 certification

3. Working Principle & Equipment Compatibility

Innovative Working Principle

The 9YG-1.25 operates on a "Cut-Crush-Compress" sequence essential for tough crops like corn stalks.

1. Intake: The machine is towed offset or inline. The Hammer Claw Pickup rotates at high speed, shattering the tough root structure of the standing corn and lifting the stalk.

2. Feeding: The harvested material is immediately engaged by the Auger and Tine Roller system. This forced-feeding mechanism actively grabs the bulky material and pushes it into the bale chamber, preventing the "bridging" effect common in gravity-fed systems.

3. Compression: Inside the chamber, 18 steel rollers rotate to tumble the material. As more material enters, the hydraulic pressure on the rear gate resists expansion, compressing the forage from the core outward. This creates a dense outer shell for weather protection and a breathable core.

4. Binding & Ejection: Once the preset density (monitored by sensors) is reached, the automatic net binding system triggers. The rear gate opens hydraulically, ejecting the finished bale.

4. Equipment Compatibility Matrix

Our balers are designed to be universally compatible with major tractor brands found in Korea, Europe, and the Americas.

Component EVER-POWER 9YG-1.25 Spec Compatible Tractor Brands (Examples) PTO Spline Standard 6-Spline / 8-Spline (Adaptable) John Deere, LS Mtron, Daedong (Kioti), TYM Power Output Min. 120 HP (88.2 kW) Kubota M Series, New Holland T6, Case IH Maxxum Hydraulic Output 1-2 Sets of Dual Acting Valves Universal ISO Hydraulic Couplers Hitch Type Drawbar (Traction) Standard Agricultural Drawbar Category 2/3 *Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

5. Engineering Overview: The 9YG-1.25 Advantage

In the realm of modern agricultural machinery, the 9YG-1.25 Round Baler stands as a specialized solution addressing one of the most challenging aspects of forage harvesting:

The collection of coarse, standing crops like corn stalks. Unlike traditional balers that require crops to be cut and raked into windrows beforehand, the 9YG-1.25 introduces a revolutionary Hammer Claw Pickup mechanism. This engineering marvel allows operators to harvest standing corn stalks directly. By combining the cutting, crushing, and collecting processes into a single pass, this machine significantly reduces fuel consumption and labor costs associated with multiple field passes.

The structural integrity of the 9YG-1.25 is built upon a robust chassis designed to withstand the high torque and vibration inherent in processing thick biomass. The core compression system utilizes a roller-type chamber consisting of 18 high-strength steel rollers (Φ 222mm diameter). This steel-roll design is superior to belt-based systems for heavy, wet silage applications because it prevents belt slippage and ensures consistent rotation of the bale, even when the crop moisture content is high.The machine is engineered to produce bales with dimensions of Φ1200mm × 1250mm, optimizing volume for transport logistics while maintaining a high density of up to 200 kg/m³.

Furthermore, the feeding mechanism is a critical differentiator. It employs a complex "Auger + Tine Roller + Drum" system. This forced-feeding architecture ensures that the collected material is evenly distributed across the width of the bale chamber, resulting in perfectly cylindrical bales with firm edges. This is particularly vital for the South Korean market, where storage space is premium and "Hanwoo" cattle farmers demand high-quality, mold-free roughage. The automated net binding system wraps the bale tightly in seconds, securing the nutrients and ensuring the bale holds its shape during multiple handling stages in the logistics chain.

6. Application Scenarios

6.1. Corn Stalk Harvesting for Biomass Energy

Ideal for harvesting standing corn stalks to be used for biomass energy production, the 9YG-1.25 can efficiently collect and bale corn residues in a single pass, reducing the need for multiple field operations.

6.2. Silage Production for Dairy and Beef Cattle>/h3>

The 9YG-1.25 is perfect for producing high-quality silage from wet crops like corn, rye, or alfalfa. Its high-density bales preserve the moisture content, making it ideal for livestock feed and ensuring nutrient retention during fermentation.

6.3. Rice Straw Management in Paddy Fields

For areas where rice straw must be collected and managed for environmental reasons, this baler efficiently picks up and compacts rice straw into dense, transportable bales, supporting sustainable agriculture practices and reducing field burning.

6.4. Straw Collection for Bedding and Mulching

Farmers who need to collect straw for use as bedding in livestock barns or as mulch for vegetable and fruit crops will find the 9YG-1.25's high-density baling system effective, ensuring ease of storage and transport.

6.5. Harvesting Alfalfa for Livestock Feed

The 9YG-1.25 handles alfalfa and other hay crops efficiently, preserving the nutritional value of the bales. It’s an ideal machine for farms producing forage crops for the livestock industry, providing uniform and tightly bound bales.

6.6. Energy Crop Harvesting (Miscanthus, Switchgrass)

This baler is ideal for harvesting energy crops like Miscanthus or Switchgrass, which are grown for biomass energy production. Its ability to handle dense, tall crops with ease makes it well-suited for this growing sector.

6.7. Harvesting Pasture Grass for TMR (Total Mixed Ration)

The 9YG-1.25 is great for harvesting pasture grasses for TMR used in animal feed. Its ability to quickly bale large quantities while maintaining bale density makes it perfect for commercial feed producers who need to manage large-scale operations.

6.8. Post-Harvest Crop Residue Management

After grain or vegetable harvests, the 9YG-1.25 collects and bales leftover crop residues like wheat straw, barley, or soy stubble. This helps improve soil health by promoting sustainable residue management practices, and the bales can be used for various purposes, such as bedding or energy.

6.9. Eco-Friendly Straw Baling for Carbon Footprint Reduction

With increasing regulations on burning agricultural waste, the 9YG-1.25 allows farmers to comply with environmental standards by turning crop residues into valuable bales for renewable energy or organic matter recycling, helping reduce their carbon footprint.

6.10. Biomass Feedstock for Biofuel Production

Farmers growing energy crops such as switchgrass or other biomass plants can use the 9YG-1.25 to harvest and bale large quantities for biofuel production, contributing to the growing demand for sustainable energy solutions.

7. Regulatory Compliance & Environmental Impact (Focus: South Korea)

South Korea: The agricultural landscape in South Korea is heavily influenced by the Clean Air Conservation Act and the Ministry of Agriculture, Food and Rural Affairs (MAFRA) policies. Open burning of agricultural residue, such as rice straw and corn stalks, is strictly prohibited to combat fine dust pollution (PM2.5). This regulatory environment creates a mandatory need for efficient baling equipment. The 9YG-1.25 directly supports compliance by efficiently converting "waste" stalks into valuable biomass resources. Furthermore, the Korean government often provides subsidies (via NACF) for machinery that promotes "eco-friendly agriculture" and domestic forage production to reduce reliance on imported hay. Our equipment meets the durability and safety standards required for these subsidy programs.

Global Context (EU & China): Similarly, in China, the "Blue Sky Defense War" policy mandates the comprehensive utilization of crop straw. The 9YG-1.25 is designed to meet these exact needs, turning potential fire hazards into livestock feed or biomass fuel. In the European Union, the Common Agricultural Policy (CAP) incentivizes soil conservation and carbon footprint reduction. By using the 9YG-1.25 to remove stalks for biomass energy or bedding, farmers contribute to a circular bio-economy. The machine's ability to handle standing crops also implies less soil compaction due to fewer tractor passes, aligning with global soil health directives.

8. Market Trend Analysis: Why Biomass Baling is the Future

The global shift towards renewable energy and sustainable agriculture is driving the demand for high-efficiency stalk balers. In South Korea, the government's "Renewable Energy 3020" implementation plan aims to increase renewable energy generation to 20% by 2030. Agricultural biomass (corn stover, rice straw) is a key component of this strategy. Traditional balers often struggle with the rigid structure of corn stalks, leading to equipment failure and low density.

The trend is moving towards "Single-Pass Harvesting" machinery like the 9YG-1.25. Farmers no longer want to mow, rake, and then bale; they want to drive once and finish the job. This reduces soil compaction—a critical factor for preserving the long-term fertility of paddy fields and dry fields alike. Furthermore, with the rising cost of imported animal feed, domestic production of high-quality corn silage bales has become an economic necessity for beef and dairy farmers. The 9YG-1.25 addresses these macroeconomic trends by offering high density (lower transport cost) and high durability (lower maintenance cost).

9. About Us | EVER-POWER

We are not just an assembly plant; we are a comprehensive manufacturing hub equipped with CNC laser cutting machines, automatic welding lines, and electrostatic spraying production lines.

Customization Services (OEM/ODM): We understand that agricultural conditions vary by region. We offer extensive customization services for our global partners:

- Color & Branding: We can apply your corporate color scheme and branding (Logo/Decals) to the machinery to align with your local dealership identity.

- Technical Adaptation: We can adjust the PTO input speed (540/720/1000 RPM) or hitch geometry to match specific tractor models prevalent in your region (e.g., adapting for specific Korean or Russian tractor hitches).

- Pickup Modification: While the Hammer Claw is standard for corn, we can configure the machine with specialized Spring Teeth for regions primarily harvesting Alfalfa or Oats.

We actively participate in international expos like the China-Russia and China-Mongolia Expos, ensuring our technology remains at the forefront of the industry.

10. Customer Success Story: Transforming Forage in Gangwon-do

"The 9YG-1.25 has really proven its worth in our corn fields. We were struggling with previous models getting clogged with wet crops, but this one performs like a charm. It's built tough and can handle the dense corn stalks without a hitch. Plus, the automatic net wrap saves us time and effort."

— Sung Mi, Agricultural Contractor, South Korea

"We run a large livestock farm, and this baler helps us stay on top of the forage collection. The productivity is impressive—40 to 80 bales per hour, depending on the crop conditions. It’s helped us keep up with demand, and the bale density is spot on for transport efficiency."

— Ryan L., Dairy Farmer, Jeju Island

"We’ve used several balers in the past, but none hold up like the 9YG-1.25. It’s been running smoothly with minimal maintenance for over a year now. The quality of the bales is excellent, and it’s much easier to handle. The system is efficient and works well with our tractors."

— Tae Min, Farm Manager, Gangwon-do

"We needed a baler that could handle both grass and corn in our fields. The ability to switch between the Hammer Claw and Spring Tooth pickup systems made this baler ideal for our needs. It’s great to have a machine that’s so adaptable to different crops."

— Kaito S., Agricultural Equipment Specialist, Japan

"We started using the 9YG-1.25 for silage production, and it’s made a big difference in the quality of our feed. The bales come out with great density, and the automated net wrap is so convenient. It’s also less harsh on the fields, which is important for sustainable farming."

— Minji P., Silage Producer, South Korea

11. Related products

11.1 Gearbox:

Compatible models: EP-FK263 (square baler), EP-RC30 series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:Compatible Models: EP-PTO series (1-3/8" Z6 spline, adjustable length 600-1200mm).Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.Why it's suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.11.2 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.Why it's suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.11.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.Why it's suitable: High-cycle durability, compatible with Bondioli & Pavesi.11.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.* Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.* Parameters vary depending on working conditions; please refer to the actual drawings. It is recommended to confirm interface dimensions before selection.

11. Frequently Asked Questions (FAQ)

Q1. What is the approximate price of the 9YG-1.25 round baler including shipping to Busan port, South Korea?

A1. The price varies based on order volume and current steel costs. However, as a direct manufacturer, we offer highly competitive factory-direct pricing significantly lower than European counterparts. Please click "Inquire Now" for a precise CIF Busan quote within 24 hours.

Q2. Can this baler handle wet corn stalks for making silage, or is it only for dry straw?

A2. Absolutely. The 9YG-1.25 is specifically engineered for high-moisture silage applications. Its roller-type chamber and robust feeding system prevent the slippage that belt balers experience with wet crops, ensuring dense, air-tight bales ideal for fermentation.

Q3. Which local tractors in Korea are compatible with the power requirements of this baler?

A3. The 9YG-1.25 requires a minimum of 88.2kW (approx. 120HP). It is fully compatible with popular Korean models such as the LS Mtron XP series, TYM T130, or Daedong (Kioti) HX series, provided they have a standard 540 RPM PTO and hydraulic outputs.

Q4. How do I switch between the Hammer Claw and the Spring Tooth pickup systems?

A4. The pickup system is modular. While it requires some workshop time, the interchangeability allows you to use one machine for two purposes: Hammer Claws for standing corn stalks in autumn, and Spring Teeth for windrowed grass in spring. We provide detailed video tutorials for this process.

Q5. What is the lead time for a customized order with our company branding?

A5. For standard customization (color and logo), our production cycle is typically 15-20 days. Including shipping logistics to South Korea, you can expect to receive the equipment roughly 30-45 days after order confirmation.

Q6. Where can I find replacement parts like pickup tines or rollers if they break?

A6. We maintain a robust inventory of spare parts. We can ship urgent parts via air freight to Korea. Additionally, many components like bearings and chains use international standard sizes (ISO) and can be sourced locally if needed.

Q7. Does this machine come with a warranty and technical support for installation?

A7. Yes, we provide a 12-month warranty on core components. We offer comprehensive online technical support, installation manuals in English, and video guidance. For large orders, on-site engineer support can be negotiated.

Ready to Optimize Your Harvest?

Contact EVER-POWER today for specs, dealership opportunities, and best pricing.

Editor: PXY