Beschrijving

1. Technical Specifications & Parameters

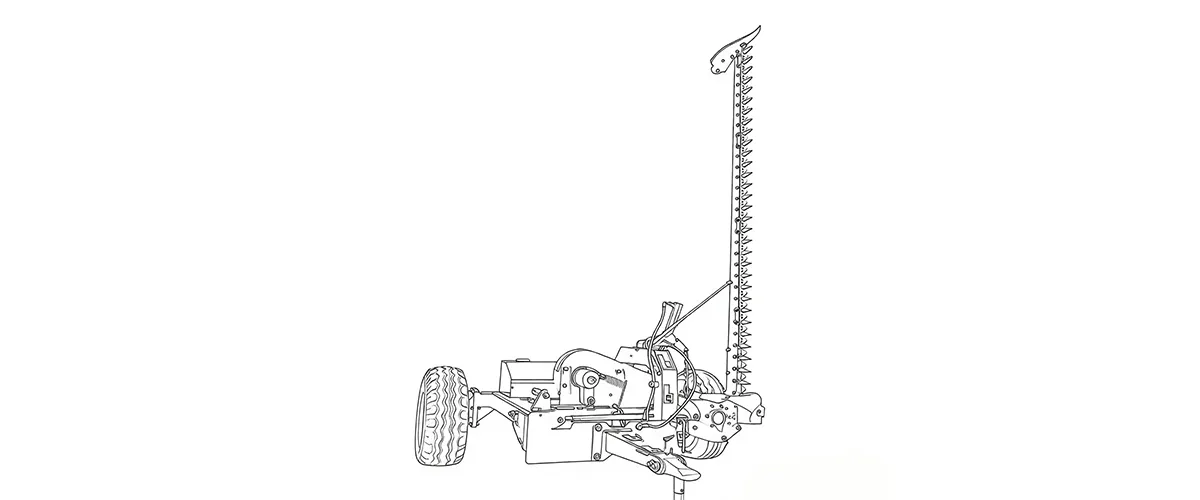

| Nee. | Item | Eenheid | Specificatie |

|---|---|---|---|

| 1 | Modelnaam | / | 9GD-2.5 Trailed Single Blade Mower Upgraded version |

| 2 | Type trekhaak | / | Gevolgd |

| 3 | Snijstructuurtype | / | wederkerig |

| 4 | Snijbreedte | M | 2.5 |

| 5 | Overeenkomend vermogensbereik | kw | 15-35 |

| 6 | Werksnelheidsbereik | km/u | 6-10 |

| 7 | Aantal bewegende bladen | stuks | 34 |

| 8 | Dimensions (Length × Width × Height) | mm | 2000×4300×950 |

| 10 | Vermogensuitgangsassnelheid | r/min | 540 |

| 11 | Gemiddelde maaihoogte | mm | 50-70 |

| 12 | Productiviteit | hm2/h | 2.0-3.0 |

| 13 | Aantal operators | (personen) | 1 |

| 14 | Structuurgewicht | kg | 490 |

2. Advanced Cutting Technology & Application Scenarios

3. Global Regulatory Standards & Compliance

4. Market Trend Analysis: The Future of Forage Harvesting

The global agricultural sector is witnessing a significant shift towards “precision harvesting.” In South Korea, where the aging rural population is creating a labor shortage, there is an increasing demand for machinery that offers high hectares-per-hour (ha/h) efficiency with minimal maintenance. The 9GD-2.5 Towed Single-Blade Lawn Mower for sale caters to this trend by providing a “set and forget” mechanical reliability. We are also seeing a movement towards offset mowers that minimize soil compaction by keeping the tractor on already-cut paths. Industry data suggests that the market for sickle-bar mowers is projected to grow by 4.2% annually as farmers recognize the superior dry-down speed of reciprocating-cut forage compared to rotary-cut crops.

5. Component Compatibility & Brand Comparison

| Brand/Component | Compatibiliteitsstatus | Key Benefit for Korean Market |

|---|---|---|

| LS Mtron / Daedong Tractors | Volledig compatibel | Direct fit for standard Category 1 & 2 hitches. |

| Jiujia 65Mn Blades | OEM Standard | Higher wear resistance than generic carbon steel. |

| Walterscheid PTO Shafts | Compatible | Enhanced safety with world-class torque protection. |

| SKF / NSK Bearings | Standardized | Easy local procurement for maintenance in Korea. |

6. Customer Success Case Study:

Client 1 Profile: South Korea, Gyeonggi-do Forage Producer

Customer Reviews:

“As a commercial forage producer in Gyeonggi-do, I rely on the 9GD-2.5 Towed Mower to maintain my alfalfa fields. The 3.2-meter cutting width means I can get through large fields quickly, which is critical during the short harvest windows. The adjustable rollers ensure that I can condition my crops perfectly, even in the wet, dense fields we have here. The machine has definitely saved us time and improved our hay quality, leading to better prices at the market.”

Client 2 Profile: United States, Midwest Alfalfa Farmer

Customer Reviews:

“Here in the Midwest, where the weather can be unpredictable, the 9GD-2.5 Mower is a game-changer. The adjustable conditioning rollers are fantastic for getting the perfect drying conditions, and the sturdy frame handles our rocky soils well. We’ve seen a 30% reduction in drying time compared to other mowers we’ve used in the past, which has greatly improved our overall productivity.”

Client 3 Profile: Australia, Queensland Livestock Farmer

Customer Reviews:

“In Queensland, we deal with a lot of heavy clay and uneven terrain. The 9GD-2.5 Mower’s towed design provides superior stability compared to mounted models. This makes it much easier to navigate the slopes and still get a uniform cut. The 540 RPM PTO works perfectly with my tractor, and I’ve been impressed with how the mower handles our challenging conditions without compromising on performance.”

Client 4 Profile: Brazil, São Paulo Forage Grower

Customer Reviews:

“We’ve been using the 9GD-2.5 Mower for over a year now on our large-scale forage operation in São Paulo. The machine’s high cutting width and robust construction make it perfect for our humid conditions, and it handles our tall grasses and dense crops with ease. The 65Mn manganese steel blades last much longer than the standard carbon steel blades we used to have, and the increased productivity has really helped us keep up with demand.”

7. EVER-POWER Factory: Customization & Quality Assurance

Onze productiefaciliteit is gevestigd in de economische en technologische ontwikkelingszone van Hulunbuir en beslaat een oppervlakte van meer dan 32.000 vierkante meter Het bedrijf is uitgerust met ultramoderne CNC-lasersnijmachines, automatische laslijnen en elektrostatische poedercoatingslijnen. We zijn niet zomaar een assemblagebedrijf; we zijn een complete fabrikant met uitgebreide R&D-capaciteiten.

Maatwerkdiensten (OEM/ODM): We begrijpen dat de landbouwomstandigheden per regio verschillen. Voor de Zuid-Koreaanse markt bieden we maatwerkopties aan, waaronder:

• Hydraulische aanpassing: Het aanpassen van de klepdrukken aan de specifieke hydraulische doorstroming van LS- of Daedong-tractoren.

• Bandenupgrades: Optioneel zijn bredere banden met extra bodemvrijheid verkrijgbaar voor rijstvelden met diepe modder.

• Kleur en merkidentiteit: OEM-merkdiensten voor dealers en distributeurs.

Wij houden vast aan ISO 9001-certificering voor kwaliteitsmanagementsystemen en zijn erkend als een nationale hightechonderneming. Elke 9YG-2.24D balenpers ondergaat een strenge test van 48 uur ononderbroken gebruik vóór verzending om te garanderen dat er bij aankomst geen defecten zijn.

8. Related products

8.1 Gearbox:

Compatibele modellen: EP-FK263 (vierkante balenpers), EP-RC30-serie (ronde balenpers, overbrengingsverhouding 1:2, compatibel met 35 mm 6-spline as).Toepassing: Brengt aftakasvermogen over naar het balenpersmechanisme, geschikt voor New Holland 630 of John Deere 535. Parameters: Koppel > 500 Nm, 20% brandstofbesparing.Waarom kiezen voor deze versnellingsbak: Aanpasbare afmetingen (verkleinbaar tot 250-300 mm), bestand tegen viskeuze verontreinigingen (rubberdampen), IP65-bescherming. PTO-as:Compatibele modellen: EP-PTO-serie (1-3/8″ Z6-vertanding, verstelbare lengte 600-1200 mm).Toepassing: Verbindt de tractor met de hoofdaandrijving van de balenpers, geschikt voor het type 9YG-1.0C. Koppeloverdrachtsrendement >95%, compatibel met SAE/EURO-flenzen.Waarom het geschikt is: Waterdicht ontwerp, geschikt voor natte silagewerkzaamheden; vervangbaar door de Weasler-serie.

8.2 Kettingen & Tandwielen:

Compatibele modellen: ANSI kettingen, met EP-tandwiel (steek 12,7-19,05 mm, roldiameter 10-12 mm).Toepassing: Gebruikt in transportbanden of bindmechanismen, geschikt voor het transporteren van vierkante/ronde strobalen. Breedte 25-40 mm, slijtvast staal.Waarom het geschikt is: Compatibel met Kobelco- of HF Group-apparatuur, vermindert het risico op kettingbreuk; voedselveilige optie beschikbaar voor kuilvoer.

8.3 Couplings:

Compatibele modellen: EP-koppeling 200-serie (koppel passend bij 500-1000 Nm).Toepassing: Verbindt de versnellingsbak met de balenpersrol en dempt trillingen.Waarom het geschikt is: Hoge duurzaamheid bij veelvuldig gebruik, compatibel met Bondioli & Pavesi.

8.4 Hydraulische cilinder:

Hydraulische cilinder: EP-HC-serie (boring 50-100 mm, slag 300-600 mm), geschikt voor het heffen van balen.Lagers en afdichtingen: 6208-2RS lagers, L10 levensduur >10000 uur, stofbestendige afdichting.Compatibiliteitstabel: Volledig uitwisselbaar met Comer 250T (koppel komt overeen, slechts 35% van de prijs); flens komt overeen met het Noord-Amerikaanse 4-bouts PTO-patroon.* Disclaimer: De hierboven genoemde merknamen dienen uitsluitend ter illustratie. Wij leveren geen originele producten of apparatuur onder deze merknamen.* De parameters variëren afhankelijk van de bedrijfsomstandigheden; raadpleeg de daadwerkelijke tekeningen. Het is raadzaam om de afmetingen van de interface te controleren voordat u een keuze maakt.

9. Agricultural Professional FAQ

Q1. How much does a professional 9GD-2.5 Towed Single-Blade Lawn Mower cost for farms in Gyeonggi-do?

A1. The **price** of the 9GD-2.5 depends on specific customization and shipping logistics to Busan or Incheon. Generally, as a factory-direct **supplier**, we offer the most competitive commercial **quotes** for high-volume orders in South Korea.

Q2. Where can I find a reliable Jiujia machinery supplier for agricultural mower parts near Seoul?

A2. Jiujia provides a direct distribution network across Korea. You can contact our **Jiujia machinery Korea** service center or request a local **supplier** list via our website to ensure you receive genuine parts and professional maintenance.

Q3. What is the recommended engine power needed to operate the towed single-blade mower efficiently in heavy grass?

A3. For the 9GD-2.5 model, we recommend a tractor with at least 20 HP. However, for dense or wet forage common in the Gangwon-do highlands, a 40-50 HP tractor will provide the reserve torque required for a consistent cutting speed.

Q4. How does the reciprocating blade technology help with high-yield alfalfa harvesting compared to standard rotary cutters?

A4. Reciprocating mowers like our **Jiujia mower** provide a clean shear cut. This prevents the “bruising” and leaf loss associated with rotary slashers, resulting in higher nutritional value and faster regrowth of the alfalfa crop.

Q5. Which type of maintenance is required for the 9GD-2.5 Towed Single-Blade Lawn Mower during the harvest season?

A5. Maintenance is straightforward: ensure the sickle bar is lubricated daily, check the blade sharpness every 50 hours of operation, and verify that the safety trip mechanism is clear of debris. Most parts are standardized for quick replacement.

Q6. Why should professional land cooperatives in Korea choose Jiujia as their primary agricultural mower manufacturer?

A6. Jiujia is a specialized **manufacturer** with 20+ years of history. We offer upgraded editions with reinforced frames and 65Mn manganese steel blades, specifically designed to withstand the rocky and demanding soil conditions found in South Korea.

Q7. How does the machine handle rocky terrain or hidden obstacles during high-speed field operations?

A7. The 9GD-2.5 (Upgraded Edition) features an automatic safety trip mechanism. If the blade hits a significant obstacle, the bar will swing back instantly, preventing structural damage to the frame or the tractor’s PTO shaft.

Q8. When is the best time to replace the manganese steel blades on a used Jiujia machinery mower?

A8. Blades should be replaced when they show signs of excessive thinning or if they cannot be sharpened back to a clean edge. Using original Jiujia blades ensures perfect balance and prevents vibration damage to the crank-link system.

Q9. What are the shipping logistics for importing agricultural machinery from Jiujia to the South Korean port of Busan?

A9. We offer comprehensive EXW, FOB, and CIF shipping terms. Most orders for the 9GD-2.5 series are containerized and shipped directly to Busan or Incheon, with full documentation provided for local customs clearance and tax benefits.

Q10. How do I adjust the cutting height of the 9GD-2.5 mower for different crop types?

A10. The cutting height is easily adjustable via the mechanical slide shoes located at each end of the sickle bar. By changing the shoe angle, you can set the cut from as low as 3cm for lawns to 8cm for tall forage.

Redacteur: PXY

*Disclaimer: De andere hierboven genoemde merknamen dienen uitsluitend ter illustratie. Wij bieden geen originele producten of apparatuur aan die onder deze merknamen worden verkocht.