Baler bulat EP-9YG-1.0C

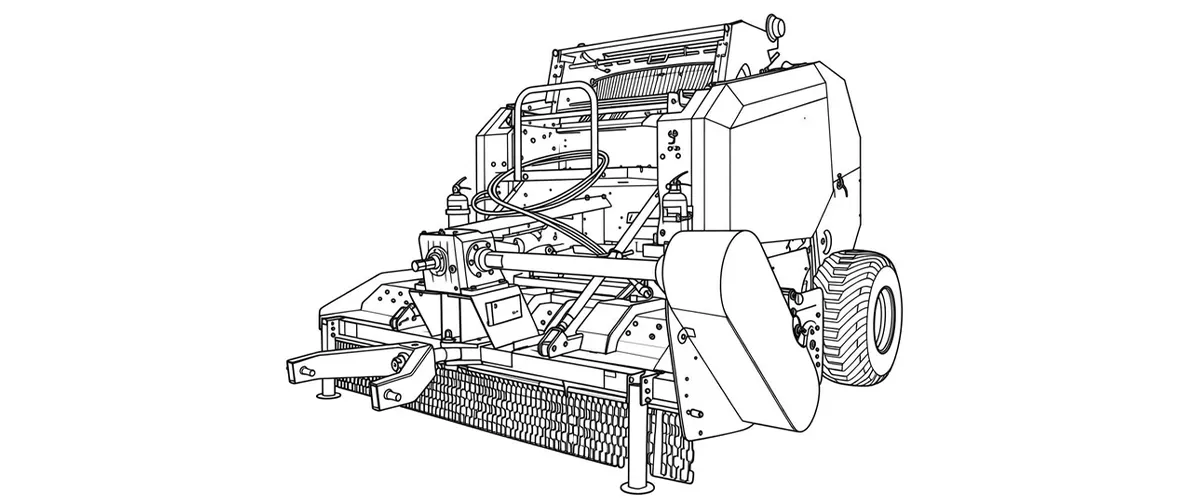

The 9YG-1.0C Round Baler by EVER-POWER is an engineering marvel specifically optimized for standing corn stalks and heavy straw applications. Featuring a unique interchangeable pickup system (Spring Tooth & Hammer Claw) and reinforced 16A heavy-duty dual drive chains, this machine eliminates the need for pre-raking, significantly reducing operational costs for farmers in South Korea and global markets. With a high-density compression capability reaching 200 kg/m³ and a robust 16-roller chamber, it ensures distinct preservation quality and efficient transport logistics for livestock feed and biomass energy sectors.

1. Technical Specifications: 9YG-1.0C Data Sheet

| Item No. | Parameter Name | Unit | Spesifikasi |

|---|---|---|---|

| 1 | Nama Model | / | 9YG-1.0C Round Baler |

| 2 | Jenis Halangan | / | Diikuti |

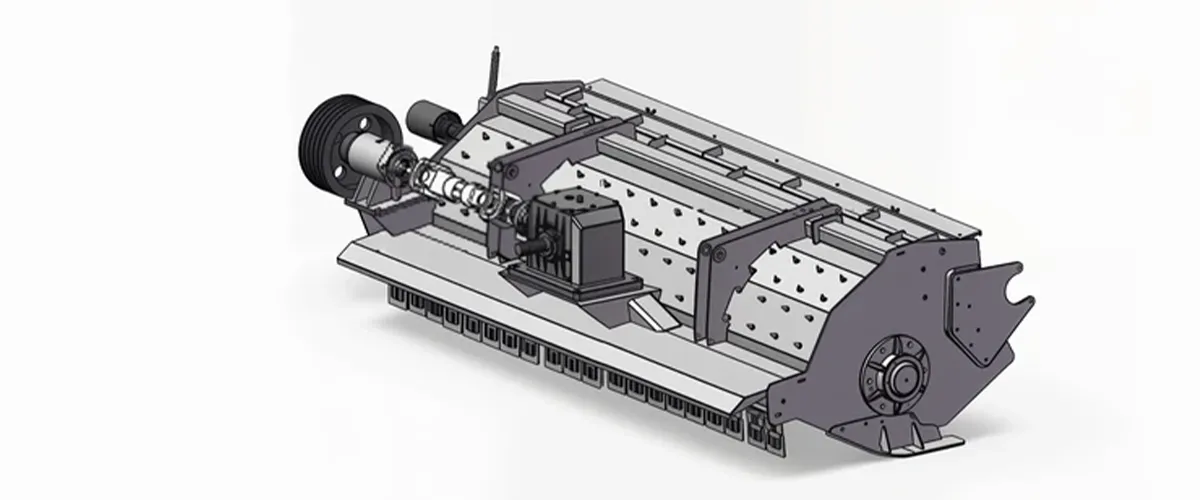

| 3 | Lebar Pengambilan | mm | 2400 |

| 4 | Jenis Struktur Pengambilan | / | Vane + Pick-Up Teeth + Roller |

| 5 | Feeding Mechanism | / | Feeding Rotor + Roller |

| 6 | Lebar Ruang Mampatan | mm | 1250 |

| 7 | Diameter Ruang Mampatan | mm | Φ1000 |

| 8 | Number of Compression Rollers | pcs | 16 (rollers) |

| 9 | Diameter Penggelek | mm | Φ222 |

| 10 | Binding Method | / | Automatic Net Binding |

| 11 | Matched Power | Kw/hp | ≥69.8 / 95 |

| 12 | Berat Struktur | kg | 3198 |

| 13 | PTO Speed | r/min | 540 |

| 14 | Dimensions (L×W×H) | mm | 3800 × 2850 × 2200 |

| 15 | Kawalan Ketumpatan Makanan | / | Kawalan Sensor |

| 16 | Forage Size (Dia × Width) | mm | Φ1000 × 1250 |

| 17 | Forage Density | Kg/m³ | 115 ~ 200 |

| 18 | Produktiviti | Bales/h | 40 ~ 80 |

| 19 | Jarak roda | mm | 2100 |

| 20 | Kelajuan Operasi | Km/h | 5 ~ 20 |

| 21 | Spesifikasi Balutan Bersih | / | 2000m x 1.25m per roll |

Looking for a smaller baler? Check this out!

2. Five Key Engineering Facts

- Dual-Mode Pickup: Industry-first interchangeable system allowing seamless switching between Spring Tooth (for grass) and Hammer Claw (for standing corn), saving raking labor.

- Heavy-Duty Drivetrain: Equipped with reinforced 16A double-sided chains on front and rear chambers to handle high-torque loads without elongation or failure.

- Optimized Bale Density: Advanced sensor-controlled density management produces bales weighing between 100kg and 200kg, ideal for Korean storage facilities.

- High Productivity: Capable of producing 40-80 bales per hour, ensuring rapid field clearance before the frost sets in northern climates.

- ISO Compatible: Fully compliant with GB/T and international safety standards, ensuring seamless integration with 95HP+ tractors via standard PTO shafts.

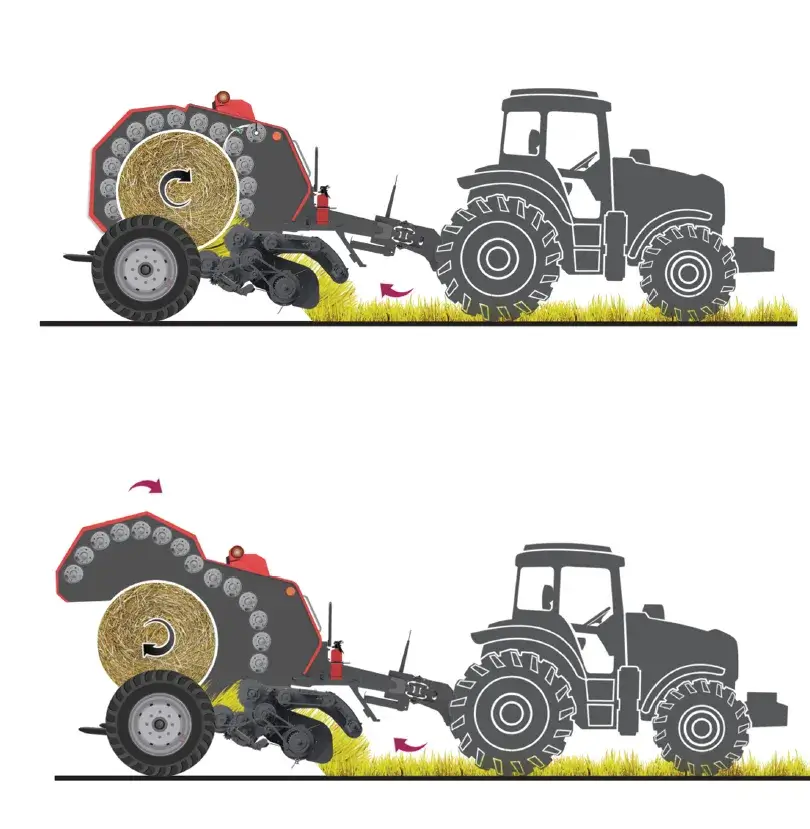

3. How It Works: Precision Engineering & Materials

The 9YG-1.0C operates on a sophisticated continuous flow principle. The Hammer Claw pickup (convertible to spring teeth) lifts the crop—whether it be swathed straw or standing corn stalks—from the field. The material is then consolidated by side augers into the central throat, where a tine roller and feeding roller aggressively force the biomass into the bale chamber. Inside the chamber, 16 high-strength steel rollers rotate to tumble the material, forming a core that grows in density as more material is added. The density is monitored by advanced sensors. Once the preset density is reached, the automatic net binding mechanism triggers, wrapping the bale securely within seconds. Finally, the rear gate opens hydraulically to eject the finished bale.

Material Science: The longevity of the 9YG-1.0C is guaranteed by premium metallurgy. The rollers are manufactured from cold-drawn seamless steel tubes with carburized surfaces for wear resistance. The gears and sprockets undergo high-frequency induction hardening to withstand the torque stresses of 95HP+ tractors. The heavy-duty 16A chains are sourced from top-tier suppliers, featuring pre-stretched alloy steel to minimize elongation over time. The exterior is coated with industrial-grade electrostatic powder paint, ensuring resistance to corrosion from humidity and fertilizers, a critical feature for the humid summers in Korea and Southeast Asia.

4. Application Scenarios

4.1. Corn Stalk Harvesting in North America

Scenario: In the cornfields of the United States or Canada, where harvesting corn stover is a common practice, the 9YG-1.0C efficiently collects standing corn stalks without requiring pre-raking. This machine minimizes fuel consumption and labor costs by combining cutting, raking, and baling into a single operation, making it ideal for large-scale operations in North America.

4.2. Rice Straw Collection in South Korea

Scenario: South Korean rice farmers benefit from the 9YG-1.0C's unique ability to handle both dry and wet rice straw without clogging. This is especially useful in areas like Gyeonggi-do, where there are strict regulations against straw burning due to air quality concerns. The baler ensures that the straw is safely collected for use as bedding or feed.

4.3. Forage Harvesting in Japan

Scenario: In Japan’s rice paddies and hilly terrains, where small-scale dairy and livestock farms are common, the 9YG-1.0C excels in providing high-density, compact bales of hay, grass, or silage. The baler's advanced density control ensures optimal bale weight, making it perfect for small to medium-scale operations.

4.4. Silage Production in Southeast Asia

Scenario: In countries like Vietnam and Thailand, where silage is a major component of livestock feed, the 9YG-1.0C handles wet forage crops such as corn stalks and grass. Its automatic net binding system ensures tight, weather-resistant bales that help maintain nutritional value during storage, perfect for silage fermentation.

4.5. Bioenergy Production from Crop Residue

Scenario: In regions focusing on renewable energy, such as Germany, the 9YG-1.0C plays a pivotal role in converting crop residues like wheat straw and corn stalks into biomass for energy production. Its high-density bales facilitate efficient transportation to biogas plants or biomass energy facilities.

4.6. Alfalfa Harvesting in California

Scenario: For alfalfa farmers in California’s arid climate, the 9YG-1.0C provides a solution for high-volume forage harvesting. Its dual-mode pickup system (Spring Tooth + Hammer Claw) allows for efficient collection of windrowed alfalfa and tough, standing forage without pre-raking.

4.7. Wheat Straw Collection in Western Australia

Scenario: In the dry, expansive wheat farms of Australia, the 9YG-1.0C effectively gathers wheat straw directly from the field, providing valuable material for animal bedding or bioenergy production. The powerful 16-roller chamber ensures that the bales remain intact even under harsh conditions.

4.8. Livestock Feed Preparation in Central Asia

Scenario: In Central Asia, where livestock farming is a critical part of the economy, the 9YG-1.0C collects various forage crops such as alfalfa, clover, and hay. The baler’s adjustable density settings allow farmers to create bales suitable for both immediate consumption and long-term storage, improving feed efficiency.

4.9. Cotton Stalk Collection for Soil Management

Scenario: In regions like India and Pakistan, where cotton is a major crop, the 9YG-1.0C is ideal for collecting cotton stalks after harvest. These stalks can be used to enhance soil quality or be processed into products like biofuels. The baler’s ability to handle tough, fibrous materials makes it a great fit for cotton farmers.

4.10. Winter Preparation in Northern Europe

Scenario: For livestock farms in colder climates, such as in Finland or Sweden, the 9YG-1.0C is used to harvest silage and hay before winter sets in. The efficient bale formation and net wrapping system ensure that feed is stored safely, minimizing spoilage and maximizing storage efficiency for winter months.

5. Environmental Compliance: Navigating Regulations in South Korea and Beyond

The adoption of the 9YG-1.0C Round Baler is not just an operational decision; it is a compliance necessity in today's regulated agricultural environment. In South Korea, the Ministry of Environment and local governments have implemented strict regulations against the open burning of agricultural by-products to combat fine dust pollution (PM2.5). The "Clean Air Conservation Act" imposes heavy fines on farmers who burn rice straw or corn stalks. Consequently, the demand for efficient baling equipment has surged, as the government subsidizes the collection of straw for livestock feed and biomass energy. The 9YG-1.0C is perfectly positioned to meet these regulatory demands by converting potential waste into valuable commodities. Its ability to collect standing stalks minimizes soil contamination, producing cleaner bales that meet the hygiene standards required by the Korean livestock industry (Hanwoo beef and dairy sectors). Furthermore, the efficient collection prevents the proliferation of pests and diseases that survive in uncollected crop residue, aligning with phytosanitary best practices.

Globally, similar trends are reshaping machinery requirements. In the European Union, the Common Agricultural Policy (CAP) incentivizes sustainable soil management and carbon sequestration. While returning some residue to the soil is beneficial, excess straw can lead to nitrogen immobilization. The 9YG-1.0C allows farmers to precisely manage residue levels, baling the excess for the growing bio-economy. In China, the "Blue Sky Protection Campaign" has strictly banned straw burning across vast regions, mandating comprehensive utilization of straw. The 9YG-1.0C’s design, which integrates cutting and baling, directly supports these policies by making straw recovery economically viable. In the United States and Canada, where corn stover harvest for cellulosic ethanol is a growing industry, the requirement for low-ash content in bales makes the 9YG-1.0C’s ability to pick up clean stalks without gathering soil stones a critical technical advantage.

6. Compatibility & Interchangeability

| Component | EVER-POWER 9YG-1.0C Standard | Compatible Replacements / Standards |

|---|---|---|

| PTO Shaft | Standard 6-Spline, 540 RPM | Fits replacement for Walterscheid, Bondioli & Pavesi shafts (Size 6/8) |

| Tractor Hitch | Adjustable Drawbar Eye | Compatible with John Deere, Kubota (M Series), LS Tractor, TYM hitch systems |

| Binding Net | 2000m x 1.25m Rolls | Universal fit for standard agricultural net wrap (Tama, Novatex equivalents) |

| Hydraulic Couplers | ISO 5675 / 7241-1 A Quick Connect | Universal standard used by Massery Ferguson, New Holland, and Case IH |

*Penafian: Jenama lain yang dinyatakan di atas disediakan semata-mata untuk tujuan ilustrasi. Kami tidak menawarkan produk atau peralatan asli yang mempunyai jenama ini.

7. Engineering Excellence: The 9YG-1.0C Round Baler Deep Dive

The agricultural machinery landscape is shifting towards versatility and durability, and the 9YG-1.0C Round Baler stands at the forefront of this evolution. Unlike traditional balers that require crop residue to be windrowed before collection, the 9YG-1.0C is engineered with a specialized Hammer Claw pickup mechanism. This robust design allows the machine to directly harvest and pulverize standing corn stalks, effectively combining the steps of cutting, raking, and baling into a single pass. For farmers in regions like Gyeonggi-do or Chungcheongnam-do in South Korea, where time windows between harvest and winter are short, this feature alone can reduce operational fuel costs by approximately 30% and labor hours by 40%. The machine's chassis is constructed from high-tensile steel, providing the rigidity necessary to withstand the vibration and impact of processing tough, fibrous stalks without structural fatigue. Furthermore, the integration of an automatic net binding system ensures that the high-density bales retain their shape during transport, reducing losses and maintaining nutritional value for silage applications.

Reliability in the field is governed by the quality of the transmission system. The 9YG-1.0C addresses common industry failure points by upgrading the standard chain drive system. It utilizes double-sided 16A heavy-duty chains for both the front and rear chambers. In mechanical engineering terms, this upgrade significantly increases the tensile strength and fatigue limit of the drive system, allowing for higher compression forces without the risk of chain snapping or skipping teeth under peak loads. This is particularly crucial when baling wet or heavy crops, where the torque requirement spikes. The compression chamber itself features 16 reinforced steel rollers with a diameter of 222mm. These rollers are designed with specific ribbing profiles to ensure aggressive crop rotation and bale formation, preventing "bale stall" even when dealing with slick or short-straw materials.

8. Market Trends: The Shift to Smart Baling

In markets like South Korea, Japan, and Germany, the trend is moving away from simple waste disposal towards valuing crop residue as a primary resource for bio-energy and high-fiber animal feed. This drives the demand for machines like the 9YG-1.0C that offer higher density compaction to reduce transport logistics costs. Furthermore, there is a growing trend towards "One-Pass" operations to minimize soil compaction and fuel usage. The 9YG-1.0C’s ability to process standing stalks aligns perfectly with conservation tillage practices.

9. About us丨EVER-POWER Factory

At EVER-POWER, we understand that agriculture conditions vary from the rice paddies of Asia to the cornfields of the Americas. Our state-of-the-art manufacturing facility is not just an assembly line; it is a hub of customization.

We offer bespoke services for the 9YG-1.0C model to suit local requirements.

This includes:1. color customization to match your brand fleet,

2. PTO spline adaptation for specific regional tractor models (e.g., 8-spline for Russian markets),

3. and hitch modification for varied terrain clearances.

Our R&D team uses advanced CAD simulation to stress-test specific modifications before production. We welcome OEM/ODM partnerships, ensuring that our high-performance balers carry your brand with the reliability of EVER-POWER engineering.

10. Customer Success Story

"As a small-scale dairy farmer, the 9YG-1.0C has been a fantastic addition to our operations. It’s really efficient in handling alfalfa and grass, and the automatic net binding system keeps everything neat and secure. The compact size makes it perfect for our hilly terrain, and it’s definitely improved our productivity."

---Mika from Japan

"We have a large cornfield, and using the 9YG-1.0C Round Baler has made our harvest process so much smoother. The bale density control feature is a lifesaver—ensures we get perfect bales every time. It’s very easy to use, and it saves a lot of time. I couldn’t ask for a better baler for our needs!"

---Carlos from Argentina

"I’ve tried a few different balers, but the 9YG-1.0C really stands out. The ability to switch between the Spring Tooth and Hammer Claw systems is amazing. It handles everything from hay to corn stalks with ease, and the high-density bales are perfect for our storage needs. Very happy with the performance!"

---Olga from Ukraine

"We farm several hectares of barley and wheat in northern Germany, and this baler has really upped our game. The 9YG-1.0C handles all the straw, and it compresses the bales tightly, reducing transport costs. The machine’s durability and speed are also impressive. It works like a charm in these tough conditions."

---Thomas from Germany

"I’ve been in farming for decades, and this baler is by far the best I’ve used. The 9YG-1.0C is fast, reliable, and very efficient at collecting corn stalks. It saves us so much time by not needing a separate raking pass, and the automatic net binding system makes the bales easy to transport. Great value for the price!"

---Jin from South Korea

11. Produk berkaitan

11.1 Kotak Gear:

Model yang serasi: EP-FK263 (pengikat segi empat sama), siri EP-RC30 (pengikat bulat, nisbah penghantaran 1:2, serasi dengan aci 6-spline 35mm).Aplikasi: Menghantar kuasa PTO ke mekanisme pengedap, sesuai untuk New Holland 630 atau John Deere 535. Parameter: Tork > 500 Nm, penjimatan bahan api 20%.Mengapa memilih kotak gear ini: Saiz boleh disesuaikan (boleh dikurangkan kepada 250-300mm), tahan terhadap bahan cemar likat (asap getah), perlindungan IP65. Aci PTO:Model Serasi: Siri EP-PTO (spline Z6 1-3/8", panjang boleh laras 600-1200mm).Aplikasi: Menyambungkan traktor ke pemacu utama baler, sesuai untuk jenis 9YG-1.0C. Kecekapan penghantaran tork >95%, serasi dengan bebibir SAE/EURO.Mengapa ia sesuai: Reka bentuk kalis air, sesuai untuk operasi silaj basah; boleh digantikan dengan siri Weasler.

11.2 Rantai & Sproket:

Model Serasi: ANSI #50/#60 rantai, dengan EP-Sprocket (pitch 12.7-19.05mm, diameter penggelek 10-12mm).Aplikasi: Digunakan dalam tali sawat atau mekanisme pengikat, sesuai untuk pengangkutan jerami pembalut segi empat sama/bulat. Lebar 25-40mm, bahan keluli tahan haus.Mengapa ia sesuai: Sesuai dengan peralatan Kobelco atau HF Group, mengurangkan risiko rantai putus; pilihan gred makanan tersedia untuk silaj.

11.3 Gandingan:

Model Serasi: Gandingan EP siri 200 (pemadanan tork 500-1000 Nm).Aplikasi: Menyambungkan kotak gear kepada penggelek pengedap, meredam getaran.Mengapa ia sesuai: Ketahanan kitaran tinggi, serasi dengan Bondioli & Pavesi.

11.4 Silinder Hidraulik:

Silinder Hidraulik: Siri EP-HC (lubang 50-100mm, lejang 300-600mm), sesuai untuk mengangkat bale.Galas dan Pengedap: Galas 6208-2RS, jangka hayat L10 >10000 jam, pengedap kalis habuk.Jadual Keserasian: Boleh ditukar ganti sepenuhnya dengan Comer 250T (pemadanan tork, hanya 35% daripada harga); bebibir sepadan dengan Corak PTO 4-Bolt Amerika Utara.* Penafian: Jenama lain yang dinyatakan di atas disediakan semata-mata untuk tujuan ilustrasi. Kami tidak menawarkan produk atau peralatan asli yang mempunyai jenama ini.* Parameter berbeza-beza bergantung pada keadaan kerja; sila rujuk lukisan sebenar. Adalah disyorkan untuk mengesahkan dimensi antara muka sebelum pemilihan.

12. FAQ

Q1. How does the 9YG-1.0C's hammer claw pickup system save money for corn farmers in South Korea?

A1. The hammer claw pickup on the 9YG-1.0C is specifically engineered to harvest standing corn stalks directly. This eliminates the need for a separate stalk shredding and raking pass, effectively reducing fuel consumption and labor costs by up to 40%, which is crucial for Korean farmers facing high operational costs.

Q2. What is the minimum tractor horsepower required to operate this round baler efficiently on hilly terrain?

A2. While the technical specification lists a minimum requirement of 95 HP (69.8 kW), for hilly terrains common in regions like Gangwon-do, we recommend using a tractor with at least 100-110 HP to ensure consistent PTO speed and safe traction while towing the 3.2-ton machine.

Q3. Can I purchase replacement parts like heavy-duty 16A chains and pickup teeth directly from EVER-POWER?

A3. Yes, EVER-POWER provides comprehensive after-sales support. You can order authentic replacement parts, including the reinforced 16A chains, pickup hammer claws, and rollers directly from us. We ensure rapid shipping to minimize downtime during the critical harvest season.

Q4. Does the 9YG-1.0C round baler comply with South Korean agricultural machinery safety and subsidy standards?

A4. Absolutely. Our machinery is manufactured adhering to strict ISO 9001 quality standards. We can provide all necessary documentation required for NACF (Nonghyup) loans and government agricultural machinery subsidy applications in South Korea upon request.

Q5. What is the difference between the Spring Tooth and Hammer Claw pickup options available for this model?

A5. The Spring Tooth pickup is ideal for collecting windrowed grass, rice straw, and wheat straw, offering gentle handling to preserve leaves. The Hammer Claw is a robust option designed for heavy, thick-stemmed crops like standing corn stalks, crushing them slightly to improve fermentation in silage bales.

Q6. How does the net binding system compare to traditional twine binding for bale preservation?

A6. The 9YG-1.0C uses an automatic net binding system which is far superior to twine. Net wrapping covers the entire width of the bale, significantly reducing crop loss during transport, providing better weather protection, and maintaining a tighter bale shape for easier stacking and storage.

Q7. What is the typical lead time for shipping a container of these balers to Incheon or Busan port?

A7. For standard orders, our production lead time is typically 15-20 days. Shipping from our factory to major Korean ports like Incheon or Busan usually takes an additional 3-7 days, making it a very fast solution for urgent harvest requirements.

Q8. Can this baler handle wet silage crops effectively without clogging the feeding chamber?

A8. Yes, the 9YG-1.0C utilizes a "Force Feeding" mechanism with an auger and tine roller system designed to handle high-moisture crops. The 16-roller chamber design also ensures continuous rotation of wet heavy material, preventing the "bale stall" often seen in belt balers.

Q9. Where can I find the price list or get a specific quote for the 9YG-1.0C model?

A9. Pricing varies based on customization options (pickup type, color) and shipping terms. For the most accurate and competitive price, please click the "Get a Quote" button on this page or contact our sales team directly at [email protected].

Q10. Is technical training available for operators who have never used a round baler before?

A10. Yes, EVER-POWER offers comprehensive digital training manuals, video tutorials, and live video support to ensure your operators are confident. For large orders, we can also arrange for on-site technical guidance or dealer training sessions.

Ready to Optimize Your Harvest?

Contact EVER-POWER today for specs, pricing, and shipping to South Korea.

Email: [email protected]

Editor: PXY