EP-9YG-2.24D 원형 베일러 S9000

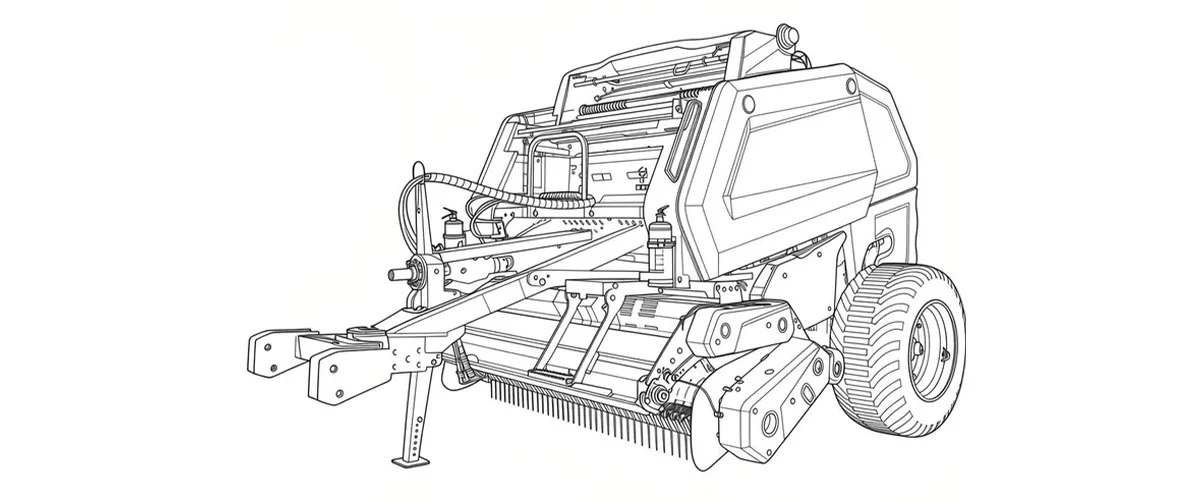

The 9YG-2.24D S9000 Round Baler offers speed, precision, and operational efficiency for modern farms. It’s built to handle the most demanding environments, providing farmers with a reliable, cost-effective solution that delivers results season after season. Whether you’re looking to streamline operations, reduce labor costs, or improve bale quality, the S9000 is your trusted partner in the field.

1. Technical Specifications (Model: 9YG-2.24D S9000 Round baler)

| 아니요. | 목 | 단위 | 사양 |

|---|---|---|---|

| 1 | 모델명 | / | 9YG-2.24D Round Baler (S9000) |

| 2 | 히치 타입 | / | 추적됨 |

| 3 | 픽업 폭 | mm | 2240 |

| 4 | 픽업 구조 유형 | / | Tine Pickup |

| 5 | 공급 메커니즘 구조 | / | 공급 로터 + 롤러 타입 |

| 6 | 압축실형 | / | 롤러 챔버 |

| 7 | 압축실 폭 | mm | 1400 |

| 8 | 압축실 직경 | mm | Φ1200 |

| 9 | 롤러 작동 부품 수 | 개 | 18개 (롤러) |

| 10 | 롤러 직경 | mm | Φ222 |

| 11 | 베일링 방법 | / | 그물 포장 |

| 12 | 필요 전력 | 킬로와트 | 55–100 |

| 13 | 구조 중량 | kg | 4262 |

| 14 | PTO 출력축 속도 | 분당 | 720 |

| 15 | 크기 (길이 × 너비 × 높이) | mm | 4240 × 3010 × 2450 (working condition) |

| 16 | 사료 밀도 조절 | / | 센서 제어 |

| 17 | 베일 크기 (지름 × 너비) | mm | Φ1300 × 1400 |

| 18 | 베일 밀도 | kg/m³ | 100~200 |

| 19 | 생산력 | 베일/시간 | 40~100 |

| 20 | 휠베이스 | mm | 2600 |

| 21 | 작동 속도 | km/h | 5~35세 |

| 22 | 네트 포장 사양 | 중 | 2000 × 1.4 / roll |

2. 주요 엔지니어링 정보

- High Compression System: Features dual-side 20A heavy-duty chains in the rear chamber, achieving bale weights between 250kg to 500kg (500-1000 jin).

- 지형 적응성: The innovative traction device allows for a 100° horizontal steering angle and a 30° lateral tilt limit, preventing driveline bind on hills.

- Massive Throughput: Capable of producing 40 to 100 bales per hour with a pick-up width of 2240mm.

- Robust Build: Weighs 4262 kg with a reinforced chassis, designed for tractors in the 55-100 kW power range.

- Advanced Binding: Utilizes an automatic net wrap system for tighter, weather-resistant bales.

3. In-Depth Product Analysis & Working Principle

Revolutionary Traction & Driveline Engineering

The most critical innovation in the 9YG-2.24D Round Baler S9000 model lies in its specialized traction and driveline system. In traditional round balers, the connection between the tractor and the implement is often a rigid point of failure, particularly when operating on the terraced fields or undulating hills common in South Korea's Gangwon-do or Jeolla-do provinces. The S9000 addresses this with a proprietary traction device engineered to withstand a maximum torque of 1000nm. This is not merely a stronger hitch; it is a dynamic articulation point. It offers a horizontal steering angle of 100 degrees, allowing for incredibly tight turning radii without disengaging the PTO. More importantly, it accommodates a lateral tilt (tractor vs. baler angle) of up to 30 degrees.

This "Super Floating" capability ensures that even if the tractor is on a slope and the baler is in a dip, the power transmission remains smooth, preventing the catastrophic driveshaft snapping that plagues lesser machines. This design dramatically reduces downtime and maintenance costs associated with universal joint failures.

Compression Mechanism & Material Science

At the heart of the S9000’s performance is its compression chamber, which utilizes a roller-type formation mechanism driven by a reinforced dual-side 20A chain system. We have moved beyond standard industrial chains to use high-grade alloy steel chains that have undergone specialized heat treatment (carburizing and quenching) to increase wear resistance and tensile strength.

The chamber houses 18 high-strength steel rollers (Φ 222mm), which are essential for creating the "bale rotation" effect. As forage enters the chamber via the 2240mm pick-up and auger system, these rollers initiate a tumbling action. The 20A chains apply immense, consistent pressure, compacting the material from the core outwards.

For silage production, High density means less air is trapped inside the bale, promoting rapid anaerobic fermentation and preventing spoilage.

For dry straw, this density translates to maximized transport efficiency, allowing farmers to load more weight per truck, significantly reducing logistics costs in the biomass energy supply chain.

6. Market Trend Analysis: The Shift to High-Density Baling

The global agricultural machinery market is witnessing a decisive shift towards "Smart Baling" and high-density biomass logistics. In developed agricultural economies, the trend is moving away from small square bales towards large round bales due to labor shortages and the need for mechanized handling. Specifically in East Asia (South Korea, Japan, China), there is a growing demand for machinery that can handle "wet crop" or silage (balage). Traditional dry hay balers often fail in these conditions due to clogging and insufficient compression.

The trend favors machines like the S9000 that utilize roller compression over belt compression for wet crops, as rollers provide better grip and rotation for heavy, damp material. Furthermore, the integration of biomass energy plants requires straw to be baled with maximum density to reduce the carbon footprint of transportation. The S9000’s capability to reach 200 kg/m³ places it at the forefront of this eco-efficiency trend, bridging the gap between field residue management and renewable energy production.

4. Global & Local Regulatory Compliance

In our primary target market, South Korea, the Ministry of Agriculture, Food and Rural Affairs (MAFRA) has implemented stringent policies regarding agricultural byproduct management to combat fine dust pollution (PM2.5). Open burning of rice straw and corn stalks is strictly prohibited in many provinces. The 9YG-2.24D S9000 is perfectly aligned with these regulations. Its high pick-up efficiency ensures that straw is removed from the field cleanly, ready for biomass power generation or livestock feed, supporting the government's "Resource Circulation" initiatives. Furthermore, the machine's safety features meet the Korea Agricultural Machinery Industry Cooperative (KAMICO) safety standards.

Globally, our manufacturing process adheres to ISO 9001 quality management systems, ensuring that every unit exported to Europe, the Americas, or Asia meets the safety requirements for heavy machinery, including emergency stop protocols and protective shielding for moving parts (as per EU Machinery Directive 2006/42/EC).

5. Compatibility & Application Scenarios

The S9000 is designed for versatility. Below is a compatibility matrix for tractors and operational environments.

| Tractor Brand Class | PTO Specification | 유압 출력 | 히치 타입 |

|---|---|---|---|

| John Deere 6M Series (or equivalent) | 1-3/8" 6-Spline, 540/720 RPM | Min 2 sets double-acting valves | Drawbar / 2-Point Hitch |

| Kubota M Series (High HP) | 1-3/8" 6-Spline, 720 RPM | Standard Flow | 드로바 |

| LS Tractor / TYM (Korean Brands) | 표준 6스플라인 | 호환 가능 | 드로바 |

Customer Success Story:

“We’ve been using the 9YG-2.24D S9000 for over 6 months now, and the performance has been outstanding. The high-density bales are a game-changer, reducing our transport costs and increasing our efficiency by at least 25%. The net wrap system is fantastic.”

— Farm Manager, South Korea

“We operate in some of the hilliest terrain in New Zealand, and the S9000’s 100° steering angle has made a huge difference. No more worrying about driveline binding or PTO disengagement on slopes. It's a durable, well-engineered machine that adapts to our tough farming conditions.”

— Agricultural Operations Director, New Zealand

“The compression system on this baler is unlike anything we’ve used before. It packs our forage into tight bales, which has dramatically improved storage efficiency. The S9000 has been a great addition to our fleet, and we’ve noticed a significant reduction in labor costs due to its automated features.”

— Farm Owner, United States

“The 9YG-2.24D S9000 has exceeded our expectations in silage production. The high-density compression means less air in the bales, promoting faster fermentation and preserving the quality of our feed. It’s well-suited for our wet crops, especially in high-humidity environments.”

— Feedlot Manager, Australia

“We've been using the S9000 for about a year now, and it's been nothing short of a workhorse. The ease of use, combined with the exceptional bale density and net wrapping technology, has made our hay and straw handling much more efficient. The machine has held up even under tough weather conditions.”

— Hay Farmer, United Kingdom

“Working on large-scale farm operations, we need equipment that can keep up with high demand. The S9000 handles our workload effortlessly, producing 80–100 bales per hour. It's a reliable, high-performance machine.”

— Large-Scale Farm Manager, Canada

10. About us | EVER-POWER: Your Partner in Custom Agricultural Solutions

At EVER-POWER, we are not just assembling parts; we are defining the standard for agricultural component manufacturing. Our facility is a state-of-the-art intelligent manufacturing hub, equipped with CNC laser cutting machines, automated welding robot lines, and electrostatic powder coating systems. We understand that one size does not fit all.

Whether you require a specific color scheme to match your OEM brand, modifications to the pick-up width for specialized row crops, or adjustments to the hydraulic interface for regional tractor compatibility, our engineering team is ready to deliver. We offer comprehensive OEM/ODM services, ensuring that the 9YG-2.24D baler fits seamlessly into your product lineup or farm operation.

Certificates and Honors:

· ISO 9001 Certification

· National High-Tech Enterprise Certificate

· Self-operated Import and Export Operation Right

· CE Certification

11. 관련 제품

11.1 변속기:

호환 모델: EP-FK263(사각 베일러), EP-RC30 시리즈(원형 베일러, 변속비 1:2, 35mm 6축 샤프트 호환).용도: PTO 동력을 베일링 메커니즘으로 전달하며, 뉴홀랜드 630 또는 존디어 535에 적합합니다. 사양: 토크 > 500Nm, 20% 연료 절감.이 기어박스를 선택하는 이유: 맞춤형 크기(250-300mm로 축소 가능), 점성 오염 물질(고무 증기)에 대한 내성, IP65 보호 등급. PTO 샤프트:호환 모델: EP-PTO 시리즈 (1-3/8" Z6 스플라인, 길이 조절 가능 600-1200mm).용도: 트랙터와 베일러 주 구동 장치를 연결하며, 9YG-1.0C 타입에 적합합니다. 토크 전달 효율은 95% 이상이며, SAE/EURO 플랜지와 호환됩니다.이 제품이 적합한 이유: 방수 설계로 습식 사일리지 작업에 적합하며, 위즐러(Weasler) 시리즈와 호환됩니다.

11.2 쇠사슬 및 스프로킷:

호환 모델: ANSI #50/#60 쇠사슬EP 스프로킷(피치 12.7-19.05mm, 롤러 직경 10-12mm) 포함.용도: 컨베이어 벨트 또는 결속 장치에 사용되며, 사각/원형 베일러의 짚 이송에 적합합니다. 폭은 25~40mm이며, 내마모성 강철 재질입니다.적합 이유: 코벨코 또는 HF 그룹 장비와 호환되며, 체인 파손 위험을 줄여줍니다. 식품 등급 옵션으로 사일리지용으로도 사용 가능합니다.

11.3 커플링:

호환 모델: EP-커플링 200 시리즈 (토크 일치 범위 500-1000 Nm).용도: 기어박스와 베일링 롤러를 연결하여 진동을 완화합니다.적합한 이유: 높은 내구성, Bondioli 및 Pavesi와 호환 가능.

11.4 유압 실린더:

유압 실린더: EP-HC 시리즈(내경 50-100mm, 스트로크 300-600mm)는 베일 리프팅에 적합합니다.베어링 및 씰: 6208-2RS 베어링, L10 수명 10,000시간 이상, 방진 씰.호환성 표: Comer 250T와 완벽하게 호환됩니다(토크 동일, 가격은 35%에 불과); 플랜지는 북미 4볼트 PTO 패턴과 일치합니다.* 면책 조항: 위에 언급된 다른 브랜드명은 예시 목적으로만 제공됩니다. 당사는 해당 브랜드명이 표시된 정품 제품이나 장비를 판매하지 않습니다.* 매개변수는 작업 조건에 따라 달라질 수 있으므로 실제 도면을 참조하십시오. 선택 전에 인터페이스 치수를 확인하는 것이 좋습니다.

Frequently Asked Questions (FAQ)

Q1. How does the S9000 round baler's wide-angle traction device specifically benefit farming operations in South Korea's hilly terrains?

A1. The S9000 features a specialized traction device with a 100° horizontal steering angle and a 30° vertical tilt. This allows the baler to articulate independently from the tractor on uneven Korean paddies or terraced fields, preventing the driveshaft from binding or snapping during tight turns and slope changes.

Q2. What is the estimated price or cost range for purchasing the 9YG-2.24D round baler for export to Asian markets?

A2. The price of the 9YG-2.24D varies based on customization options, shipping logistics to specific Asian ports, and current raw material costs. For a precise commercial quote including CIF terms to Incheon or Busan, please contact our sales team directly via the inquiry button.

Q3. S9000 원형 베일러는 일반적인 밀짚 외에 어떤 종류의 작물을 효과적으로 처리할 수 있습니까?

A3. S9000은 다용도로 활용 가능하며 옥수수 줄기(옥수수 짚), 알팔파, 젖은 벼짚, 목초, 갈대 등을 처리하도록 설계되었습니다. 견고한 롤러 및 체인 시스템은 다양한 농업 분야에서 발견되는 질기고 거친 재료를 압축하도록 특별히 설계되었습니다.

Q4. 양면 20A 중하중 체인 시스템의 장기적인 내구성을 보장하기 위해 필요한 유지 관리는 무엇입니까?

A4. 20A 체인은 내구성을 위해 열처리되었지만, 10시간 작동 후마다 체인 장력을 점검하고 적절한 윤활을 실시하는 것이 좋습니다. 자동 오일 공급 시스템은 항상 오일이 채워진 상태로 유지해야 합니다. 정기적인 점검을 통해 고밀도 압축 메커니즘의 효율성을 오랫동안 유지할 수 있습니다.

Q5. S9000 원형 베일러는 해외 구매자를 위해 현지 지원이나 예비 부품 공급이 가능한가요?

A5. 네, EVER-POWER는 글로벌 시장으로 사업을 확장하고 있습니다. 모든 제품에는 종합적인 예비 부품 키트가 제공됩니다. 해외 구매자를 위해 교체 부품에 대한 특급 배송 서비스를 제공하며, 현지 정비사가 수리를 진행할 수 있도록 디지털 기술 매뉴얼과 비디오 자료도 지원합니다.

Q6. S9000의 자동 그물 포장 시스템은 효율성 측면에서 기존의 끈 묶기 방식과 어떻게 비교됩니까?

A6. S9000의 자동 네트 랩핑 시스템은 끈을 사용할 때 몇 분씩 걸리던 묶음 시간을 단 몇 초로 대폭 단축시켜 줍니다. 또한 네트 랩핑은 날씨로부터 베일을 더 잘 보호하고, 운송 중 베일 형태를 더 잘 유지하며, 잎 손실을 줄여 영양가를 보존합니다.

Q7. OEM 파트너십을 위해 특정 색상 브랜딩이 적용된 맞춤형 S9000에 대한 공급업체 견적을 제공해 주실 수 있습니까?

A7. 물론입니다. 당사는 OEM/ODM 서비스를 전문으로 하는 제조업체로서, 귀사의 제품 라인에 맞춰 기계의 색상, 브랜딩 및 특정 기술 사양을 맞춤 제작할 수 있습니다. 맞춤 견적을 받으시려면 문의 양식을 통해 요구 사항을 제출해 주십시오.

사료 수확 효율을 높일 준비가 되셨나요?

EVER-POWER에 지금 바로 연락하셔서 S9000 원형 베일러에 대한 기술 상담, 대리점 기회 또는 직접 가격 견적을 받아보세요.

편집자: PXY