설명

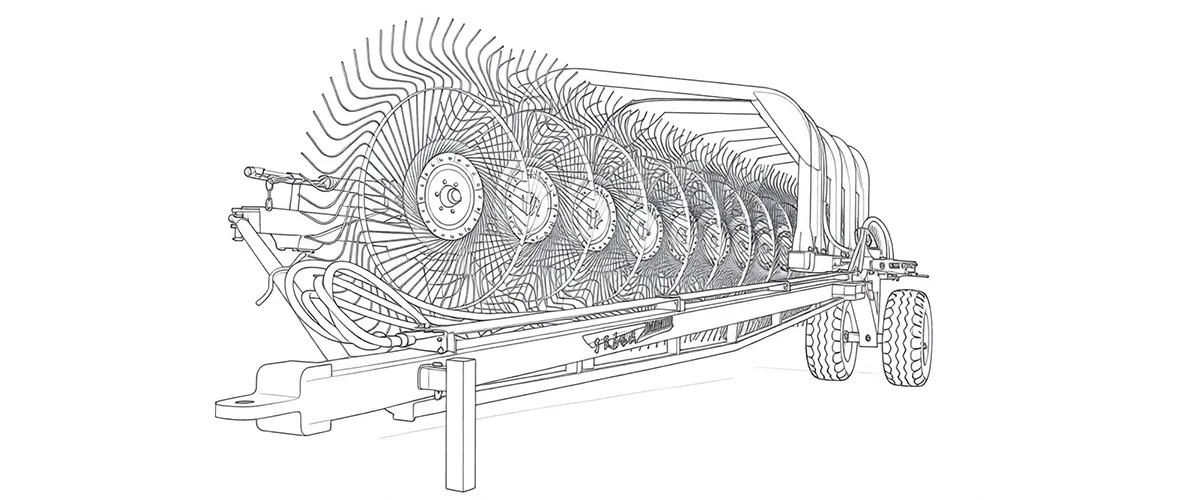

1. Technical Specifications: 9LZY-9.0 Series

| 아니요. | 목 | 단위 | 사양 |

|---|---|---|---|

| 1 | 모델명 | / | 9LZY-9.0 Finger Wheel Hay Rake |

| 2 | 구조 유형 | / | 핑거휠 타입 |

| 3 | 히치 타입 | / | 추적됨 |

| 4 | 모델 사양 | / | 9LZY-9.0 |

| 5 | 필요 전력 | 킬로와트 | 50–55 |

| 6 | 전체 크기 (길이 × 너비 × 높이) | 중 | 8.4 × 11 × 1.75 (Working Condition) |

| 7 | 기계 무게 | kg | 1100 |

| 8 | 작업 폭 | 중 | 9 |

| 9 | 작동 속도 | km/h | 8~10세 |

| 10 | 운송 속도 | km/h | 12 |

| 11 | 손가락 휠의 개수 | 개 | 15 |

| 12 | 스프링 톱니 수 | 개 | 900 (15 wheels × 60 teeth per wheel) |

| 13 | 운영자 필요 | 사람 | 1 |

| 14 | 윈드로우 너비 | 중 | 0.8–1.2 |

| 15 | 레이킹 손실률 | ≤ | 2% |

| 16 | 생산력 | hm²/h | 7.2–9 |

2. Key Facts & Performance Metrics

- Massive Coverage: 9.0m operating width utilizing 15 dynamic finger discs.

- 높은 생산성: Capable of covering 7.2 to 9 hectares per hour, ideal for tight harvest windows.

- Gentle Handling: 900 individual tines (60 per disc) ensure thorough collection without damaging crop roots.

- 유압 제어: Complete hydraulic lifting mechanism for seamless transition between work and transport modes.

- 지형 적응성: Independent floating discs follow ground contours, making it suitable for uneven terrain in Chungcheong and Jeolla provinces.

3. Redefining Forage Harvest: The 9LZY-9.0 Disc-type Hay Rake

4. Engineering Precision: Working Principles and Material Science

5. Compliance and Safety: Meeting Global & Korean Standards

Navigating the regulatory landscape of agricultural machinery is essential for safe and legal operation. For our partners in 대한민국, the 9LZY-9.0 is designed in compliance with the 농업기계화촉진법. Specifically, the hydraulic folding mechanism ensures that the machine’s transport width is reduced to safe levels for public road travel, adhering to the strict width restrictions found on rural Korean roadways. The machine is equipped with mounting points for safety reflectors and slow-moving vehicle (SMV) signage, meeting the requirements of the Korean Ministry of Land, Infrastructure and Transport (MOLIT) for towed agricultural implements.

From a land management perspective, the 9LZY-9.0 supports sustainable farming practices. Its wide flotation tires (400/60-15.5 or similar spec) are designed to minimize ground pressure. In regions like the European Union and South Korea, where soil compaction regulations are becoming stricter to preserve arable land quality, this low-impact design is a significant advantage. Furthermore, the ground-driven nature of the rake eliminates the risk of hydraulic fluid leaks associated with PTO-driven motors on the cutter bar, aligning with environmental protection standards such as ISO 14001. By choosing the 9LZY-9.0, you are ensuring compliance with current safety standards while positioning your operation for future environmental regulations.

6. Customer Success Story:

7. 에버파워 공장: 맞춤 제작 및 품질 보증

후룬부이르 경제기술개발구에 위치한 당사의 제조 시설은 1,000제곱미터가 넘는 면적을 차지하고 있습니다. 32,000제곱미터 당사는 최첨단 CNC 레이저 절단기, 자동 용접 라인 및 정전기 분말 코팅 라인을 갖추고 있습니다. 단순한 조립 업체가 아니라, 심도 있는 연구 개발 역량을 보유한 종합 제조업체입니다.

맞춤형 서비스(OEM/ODM): 저희는 지역별 농업 환경이 다양하다는 점을 잘 알고 있습니다. 한국 시장의 경우, 다음과 같은 맞춤형 옵션을 제공합니다.

• 유압 적응: LS 또는 Daedong 트랙터의 특정 유압 유량에 맞춰 밸브 압력을 조정합니다.

• 타이어 업그레이드: 진흙탕 논밭 주행을 위한 더 넓은 부력 타이어(선택 사양).

• 색상 및 브랜딩: 딜러 및 유통업체를 위한 OEM 브랜딩 서비스.

우리는 보유합니다 ISO9001 품질경영시스템 인증 또한 국가 첨단기술기업으로 인정받았습니다. 모든 9YG-2.24D 베일러는 출하 전 48시간 연속 운전 테스트를 거쳐 결함이 전혀 없는 상태로 출고됩니다.

8. 관련 제품

8.1 변속기:

호환 모델: EP-FK263(사각 베일러), EP-RC30 시리즈(원형 베일러, 변속비 1:2, 35mm 6축 샤프트 호환).용도: PTO 동력을 베일링 메커니즘으로 전달하며, 뉴홀랜드 630 또는 존디어 535에 적합합니다. 사양: 토크 > 500Nm, 20% 연료 절감.이 기어박스를 선택하는 이유: 맞춤형 크기(250-300mm로 축소 가능), 점성 오염 물질(고무 증기)에 대한 내성, IP65 보호 등급. PTO 샤프트:호환 모델: EP-PTO 시리즈 (1-3/8″ Z6 스플라인, 길이 조절 가능 600-1200mm).용도: 트랙터와 베일러 주 구동 장치를 연결하며, 9YG-1.0C 타입에 적합합니다. 토크 전달 효율은 95% 이상이며, SAE/EURO 플랜지와 호환됩니다.이 제품이 적합한 이유: 방수 설계로 습식 사일리지 작업에 적합하며, 위즐러(Weasler) 시리즈와 호환됩니다.

8.2 쇠사슬 및 스프로킷:

호환 모델: ANSI 쇠사슬EP 스프로킷(피치 12.7-19.05mm, 롤러 직경 10-12mm) 포함.용도: 컨베이어 벨트 또는 결속 장치에 사용되며, 사각/원형 베일러의 짚 이송에 적합합니다. 폭은 25~40mm이며, 내마모성 강철 재질입니다.적합 이유: 코벨코 또는 HF 그룹 장비와 호환되며, 체인 파손 위험을 줄여줍니다. 식품 등급 옵션으로 사일리지용으로도 사용 가능합니다.

8.3 커플링:

호환 모델: EP-커플링 200 시리즈 (토크 일치 범위 500-1000 Nm).용도: 기어박스와 베일링 롤러를 연결하여 진동을 완화합니다.적합한 이유: 높은 내구성, Bondioli 및 Pavesi와 호환 가능.

8.4 유압 실린더:

유압 실린더: EP-HC 시리즈(내경 50-100mm, 스트로크 300-600mm)는 베일 리프팅에 적합합니다.베어링 및 씰: 6208-2RS 베어링, L10 수명 10,000시간 이상, 방진 씰.호환성 표: Comer 250T와 완벽하게 호환됩니다(토크 동일, 가격은 35%에 불과); 플랜지는 북미 4볼트 PTO 패턴과 일치합니다.* 면책 조항: 위에 언급된 다른 브랜드명은 예시 목적으로만 제공됩니다. 당사는 해당 브랜드명이 표시된 정품 제품이나 장비를 판매하지 않습니다.* 매개변수는 작업 조건에 따라 달라질 수 있으므로 실제 도면을 참조하십시오. 선택 전에 인터페이스 치수를 확인하는 것이 좋습니다.

9. Frequently Asked Questions (FAQ)

Q1. What is the current price for the 9LZY-9.0 hay rake for a tractor delivered to Busan port?

A1. Pricing varies based on steel costs and shipping logistics. For a precise CIF Busan quote, please get in touch with our sales team directly via the “Get a Quote” button.

Q2. How wide is a 10-wheel hay rake compared to this 15-wheel 9LZY-9.0 model?

A2. A standard 10-wheel rake typically covers about 6-7 meters. The 9LZY-9.0, with 15 wheels, offers a significantly larger 9-meter width, increasing productivity by over 30%.

Q3. What is a high-capacity hay rake, and does the 9LZY-9.0 fit this category?

A3. Yes, “high capacity” refers to rakes that can cover large acreages quickly. With a 9m width and 9 hm²/h productivity, the 9LZY-9.0 is definitely classified as high capacity.

Q4. Can I use this rake as a pull-behind rake for sticks or land clearing?

A4. No, this machine is precision-engineered for forage. Using it as a pull behind rake for sticks will damage the specialized spring steel tines and void the warranty.

Q5. How long to wait before raking hay with the 9LZY-9.0 for best results?

A5. It depends on the crop, but generally, wait until the top of the swath is dry (usually 1 day after cutting). The 9LZY-9.0 can also be used to turn damp hay to accelerate drying.

Q6. Are replacement tines for this rotary hay rake style available in South Korea?

A6. Yes, we provide a spare parts kit with purchase. Furthermore, the 65Mn tines use standard international mounting, making them compatible with many local aftermarket suppliers.

Q7. Does the 9LZY-9.0 require a PTO connection to operate the spinning wheels?

A7. No, this is a ground-driven finger wheel rake. The forward motion of the tractor spins the wheels, saving fuel and simplifying maintenance compared to PTO rakes.

Q8. How does this compare to a parallel bar hay rake for alfalfa harvesting?

A8. Parallel bar rakes are gentler but slower and narrower. The 9LZY-9.0 is much faster and wider (“high capacity”), though slightly more aggressive, making it ideal for large-scale operations.

Q9. What is the Minimum Order Quantity (MOQ) for an OEM order of these rakes?

A9. We can ship single units, but for optimal shipping costs in a 40ft container, we recommend ordering 3-5 units. OEM customization usually requires a minimum of 5 units.

Q10. Can this rake handle heavy, wet rice straw common in Korean harvests?

A10. Absolutely. The Q345B frame and heavy-duty 65Mn tines are specifically tested to handle the weight and density of wet rice straw without clogging or bending.

편집자: PXY