EP-9YG-2.24D 원형 베일러 S9000 클래식

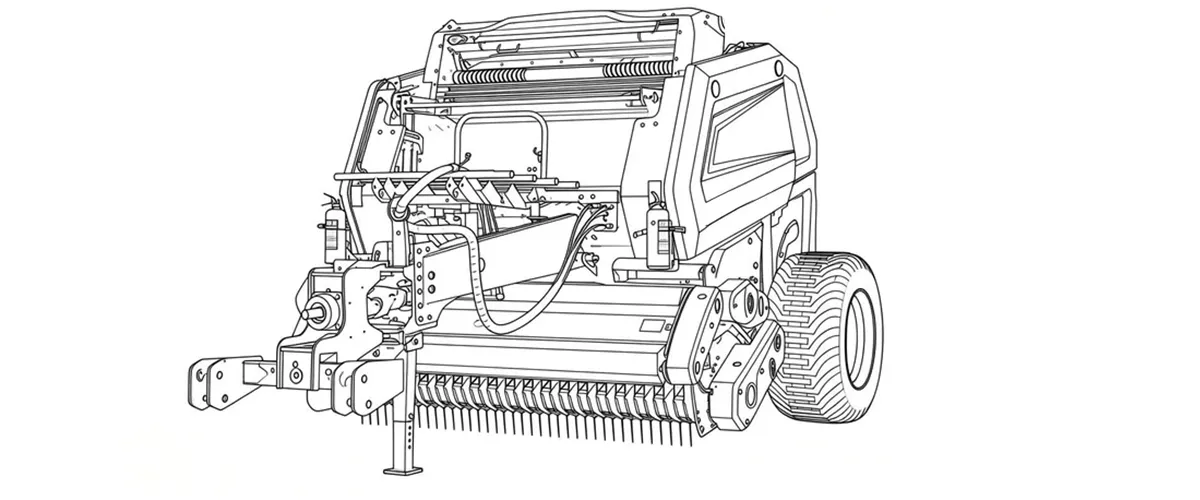

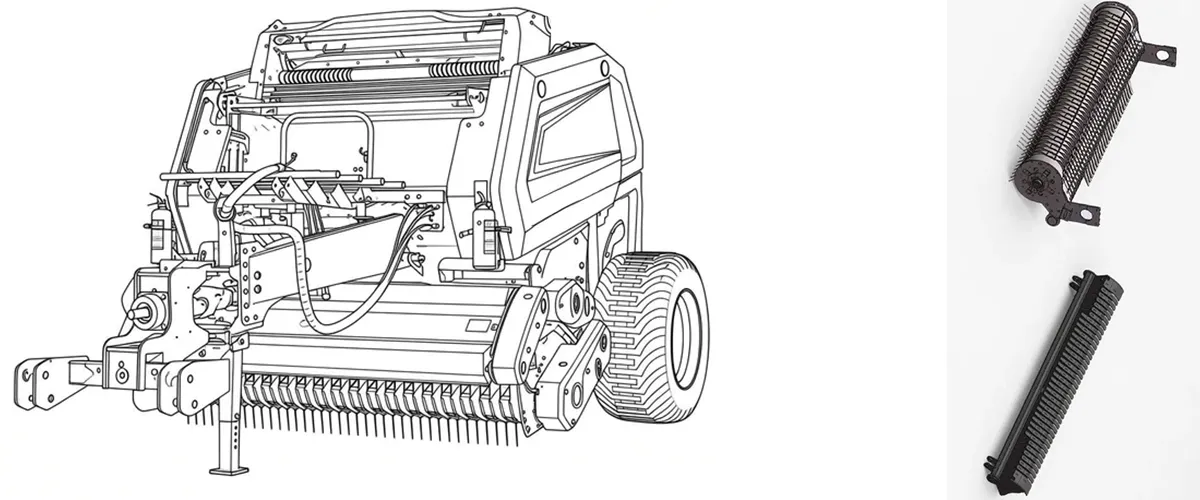

The 9YG-2.24D Round Baler (S9000 Classic) is a high-performance, durable, and energy-efficient solution for efficient crop residue management. Designed for various crops such as straw, silage, and sugarcane, this baler features a robust roller compression system, advanced feeding mechanism, and superior maneuverability. Ideal for optimizing storage and transportation, it meets global environmental regulations and offers a reliable solution for large-scale agricultural operations.

1. EVER POWER Exclusive Specifications and Parameters S9000 Classic

| Parameter | 사양 |

|---|---|

| 모델명 | 9YG-2.24D Round Baler (S9000 Classic) |

| 히치 타입 | Traction Type (Drawbar) |

| 픽업 폭 | 2240 mm |

| 압축실형 | Roller Type (18 Rollers) |

| Bale Size (Diameter x Width) | Φ1300 x 1400 mm |

| 베일 밀도 | 100 - 200 kg/m³ |

| 생산력 | 40 - 100 bales/hour |

| 매칭 파워 | 55 - 100 kW (approx. 75 - 135 HP) |

| 구조 중량 | 4312 kg |

| PTO 속도 | 720 r/min |

| Working Dimensions (L x W x H) | 4470 x 3010 x 2370 mm |

| 결합 방식 | Net Binding (Automatic) |

| Hydraulic Connection | H-Type Ferrule Joints (High Pressure) |

2. Redefining Harvest Efficiency: The S9000 Classic

3. Advantages of the 9YG-2.24D Round Baler (S9000 Classic)

3.1. Advanced Feeding Mechanism:

The 9YG-2.24D S9000 Classic employs an axial flow semi-forced feeding system. Unlike traditional models with cam tracks and retaining rings, this system significantly reduces power consumption while improving the feeding rate. It decreases the likelihood of material blockage, enhancing operational efficiency .

3.2. High Bale Density:

The round baler is equipped with 18 heavy-duty rollers, ensuring a consistent compression force that allows it to create high-density bales. This is particularly advantageous for optimizing transport logistics and storage space .

3.3. Superior Durability and Efficiency:

The dual-side heavy-duty 20A chains increase the baler's compression force, resulting in stronger and denser bales. The addition of a buffer cylinder in the rear chamber mitigates vibration during the closing cycle, enhancing the baler's lifespan and reducing wear .

3.4. Optimized Hydraulic System:

The hydraulic system features H-type ferrule joints, which increase pressure tolerance and speed up the opening and closing cycle times. Additionally, the use of these high-pressure components ensures zero leakage, aligning with environmental protection standards .

3.5. Flexible Operation:

The baler can handle a wide range of crop residues such as corn, wheat, soybeans, and pasture grass. It also supports a wide pickup width of 2240mm, ensuring efficiency during the collection phase .

3.6. Adaptability in Challenging Terrains:

The traction device features a newly designed double universal joint, allowing for better maneuverability in fields with tight turns. This mechanism also helps maintain a smooth operation during field headlands without disengaging the PTO, which decreases operator fatigue.

3.7. Improved Stability for Various Field Conditions:

The baler's structural stability is enhanced by the double-sided drive design in the rear chamber, which prevents the failure of the drive or axle during high-torque operations, especially in uneven field conditions .

4. Environmental Compliance & Global Agricultural Regulations

The shift from traditional field burning to biomass recovery is driven by increasingly stringent global environmental regulations. While industries like chemical processing focus on Regenerative Thermal Oxidizers (RTOs) to handle hazardous exhaust, the agricultural sector faces parallel mandates regarding Particulate Matter (PM2.5) reduction and Carbon Footprint management. In Australia, the National Environment Protection (Ambient Air Quality) Measure and various state-level EPA guidelines strictly regulate agricultural burning to prevent smoke haze and protect public health. Similarly, strict directives in the European Union (under the Common Agricultural Policy) and China (Law on the Prevention and Control of Atmospheric Pollution) have effectively banned straw burning, mandating mechanical harvesting and baling as the primary solution.

The 9YG-2.24D Round Baler serves as a critical tool for compliance with these legislative frameworks. By efficiently converting loose straw and residue into high-density bales, farmers can transform what was once a waste product requiring incineration into a valuable resource for biomass energy, animal feed, or paper manufacturing. Furthermore, the machine is designed in accordance with rigorous safety standards, including ISO 4254-1 (Agricultural machinery safety) and relevant Australian Standards for machinery guarding and hydraulic safety. The use of H-type ferrule joints in the hydraulic system ensures zero leakage, preventing soil contamination, which aligns with the Environment Protection and Biodiversity Conservation Act.

5. Global Trends in Forage Harvesting Technology

Application in Bazil

In Brazil, the utilization of biomass energy has become crucial in driving sustainable agriculture and green energy development. As a leading global agricultural machinery manufacturer, Ever Power provides efficient solutions for the Brazilian market, particularly in sugarcane residue management. Our 9YG-2.24D baler is specifically designed for efficiently baling sugarcane residue, compressing it into high-density round bales for easy transportation and storage.These baled sugarcane residues can not only be used as raw materials for animal feed but also converted into biomass energy, becoming an important alternative energy source. With the continuous development of biomass utilization technology, Ever Power's balers are helping farmers improve the recycling rate of sugarcane residue, reduce environmental pollution, and lay a solid foundation for renewable energy production. With Ever Power balers, Brazilian agricultural enterprises can not only reduce production costs and improve the overall utilization rate of crops but also meet the country's strict requirements for green energy and environmental regulations. Whether it's improving land use efficiency or achieving zero-waste sustainable development, Ever Power provides strong technical support to help Brazilian agriculture move towards a more environmentally friendly and efficient future.

6. Customer Success Story:

“The S9000 Classic has improved our harvesting efficiency. Our productivity has increased significantly, and the bale density is much higher. The roller-type compression chamber ensures we can handle many different types of crops, which I really appreciate. I highly recommend this machine!”

— John, Farm Manager, Queensland, Australia

“As a family business, we rely on machinery that can handle the challenges of different crops. The advantage of the 9YG-2.24D round baler is that it can handle both dry hay and high-moisture silage, making it an indispensable part of our operation. The net wrapping system has greatly improved efficiency. And the classic model is even more reliable.”— Sarah, Victoria, Australia

“We have been using the S9000 for several seasons now, and its performance has been consistently reliable. The compact design reduces maintenance requirements, making our operations smoother. Furthermore, whenever we have encountered issues requiring parts or technical support, Ever Power's customer service has been excellent, and the after-sales service is fantastic.”— Daniel, Equipment Manager, Northern Territory, Australia

“It's robust and durable, and performs perfectly even in our sandy soil conditions. The long-lasting chain system was a key factor in our purchase decision.”— Mark, Operations Supervisor, New South Wales, Australia

“Integrating Ever Power's RTO technology into our baling process was one of the best decisions I've ever made. This baler has also far exceeded our expectations in terms of speed.”— Leo, Farmer, Melbourne, Australia

7. Compatibility & Performance Comparison

| 특징 | EP 9YG-2.24D (S9000) | Standard Competitor Baler | Advantage |

|---|---|---|---|

| **Transmission** | Double-sided 20A Heavy Duty Chain | Single-sided standard chain | Balanced load, higher torque, longer lifespan. |

| **Traction Device** | Double Universal Joint + Safety Torque | Standard PTO Shaft | Smoother turning in small fields; overload protection. |

| **Hydraulic Fittings** | H-Type Ferrule (High Pressure) | Standard O-Ring Seal | Zero leakage, faster open/close cycle times. |

| **Pickup Mechanism** | Axial Flow (No Cam Track) | Cam Track System | Fewer moving parts, less maintenance, higher speed. |

| **Rear Chamber** | Equipped with Buffer Cylinder | Mechanical Stop | Reduces vibration shock, protects frame integrity. |

8. Application Scenarios

Case Study 1: Application in Large-Scale Hay Export Farms in the United StatesIn large-scale hay export farms in the United States, balers significantly improved bale density and transportation efficiency, meeting the demand for over 100,000 tons of hay annually. The EP-FK263 square baler, with a torque range of 500-2000 Nm and compatible with John Deere interface standards (SAE flange), achieved bale densities >200 kg/m³ and 20% fuel savings in applications in California or Texas farms. According to USDA data, US hay exports reached 1.5 million tons in 2024, driving the demand for mechanization.

Case Study 2: Application in China's Straw Comprehensive Utilization Industrial ParksIn China's straw comprehensive utilization industrial parks, balers optimized the biomass energy supply chain, processing over 500,000 tons of straw annually. The 9YG-1.0C round baler, with a power range of 30-120 HP and a speed ratio of 1:2-1:4, compatible with Kubota spline shafts (35mm 6-key), achieved a bale diameter of 1.0m and a 30% increase in efficiency in parks in Shandong and Henan provinces. According to the National Bureau of Statistics, China's annual straw production is 800 million tons, driving mechanization subsidy policies (agricultural machinery purchase subsidies >20%).

Case Study 3: Application in Brazilian Sugarcane Residue Energy FarmsIn Brazilian sugarcane residue energy farms, balers improved the efficiency of the bioethanol supply chain, with an annual output of over 300,000 tons of residue. With a power range of 20-100 HP and a speed ratio of 1:1-1:5, applications in São Paulo state achieved uniform bale density and compatibility with Case IH interfaces. Data from the Brazilian Ministry of Agriculture shows that Brazil is the world's largest producer of sugarcane (790 million tons/year), driving the demand for residue recycling.

Case Study 4: Application in German Precision Agriculture Organic FarmsIn German precision agriculture organic farms, balers ensured compliance with EU organic standards, processing over 100,000 tons of organic straw annually. The EP-PTO series gearbox, with DIN 6 precision and a speed ratio of 1:1.5-1:3, achieved precise baling in applications in Bavaria. EU statistics show that organic farmland accounts for 20% of Germany's total farmland, driving the demand for efficient machinery.

Case 5: Application in a Canadian Grain Straw Biomass Power PlantIn the Canadian grain straw biomass power plant, balers support the renewable energy chain, supplying >250,000 tons of straw annually. EP-Coupling 200 series couplings are used, with a torque of 500-1000 Nm, applied in Ontario, providing vibration damping. Data from the Canadian Ministry of Agriculture shows a CAGR of 6% for biomass demand.

Case 6: Large-Scale Wheat Straw Harvesting Application in RussiaIn large-scale wheat straw harvesting in Russia, balers improved export efficiency, with an annual output exceeding 400,000 tons. EP-Sprocket sprockets are used, with a pitch of 12.7mm, applied in Rostov Oblast, enabling cold-resistant operation. A report from the Russian Ministry of Agriculture shows that Russia is the world's third-largest wheat producer (80 million tons/year).

Case 7: Application in a South African Corn Stover Feed Processing PlantIn a South African corn stover feed processing plant, balers optimized the livestock supply chain, processing >180,000 tons annually. EP-HC hydraulic cylinders are used, with a bore diameter of 50-100mm, applied in Gauteng province, improving efficiency. Data from the South African Ministry of Agriculture shows a corn production of 12 million tons/year, driving feed demand.

Case 8: Application in a Thai Rice Straw Biofuel FarmIn a Thai rice straw biofuel farm, balers facilitated the renewable energy transition, with an annual rice straw volume of >120,000 tons. EP-PTO shafts are used, with a length of 600-1200mm, applied in the Central Plains, providing waterproof transmission. A report from the Thai Ministry of Agriculture shows a rice production of 20 million tons/year, with an 8% growth in biofuel demand.

9. Manufacturing Excellence & Customization Services

9.1. Require a specific color scheme to match your fleet (Red, Green, or custom)

9.2. Reinforced chassis for rocky terrain

9.3. Hitch adaptors for different tractor brands (John Deere, Case IH, New Holland, Kubota), our R&D center can accommodate your needs.

9.4. Our ability to interchange pickup systems—between standard spring teeth and hammer claws for corn stalks—demonstrates our commitment to versatility. We rigorously test every unit, ensuring it meets ISO 9001 quality standards before it leaves our factory floor.

Certificates and Honors:

· ISO 9001 Certification

· National High-Tech Enterprise Certificate

· Self-operated Import and Export Operation Right

· CE Certification

10. Replacable components

10.1 변속기:

10.2 쇠사슬 및 스프로킷:

10.3 커플링:

10.4 유압 실린더:

11. 자주 묻는 질문(FAQ)

Q1. How does the S9000's double universal joint drive shaft benefit operation in small or irregular fields?

A1. The specialized double universal joint allows for tighter turning angles without disengaging the PTO, preventing driveline binding and significantly reducing operator fatigue during headland turns.

Q2. What is the expected lifespan of the heavy-duty 20A chains compared to standard chains used in other balers?

A2. Our reinforced 20A chains are designed to withstand 30% higher torque loads, typically lasting 2-3 seasons longer than standard chains under high-density baling conditions.

Q3. Can this baler handle high-moisture silage crops, or is it strictly for dry hay and straw?

A3. Yes, the roller-type compression chamber is excellent for silage. We recommend adjusting the density settings and using high-quality net wrap to ensure anaerobic conditions for fermentation.

Q4. Is the 9YG-2.24D compatible with older tractor models that might have lower hydraulic pressure output?

A4. The unit requires a minimum of 55kW (75HP). While H-type joints handle high pressure, the system is adaptable. Please consult our technicians regarding your specific tractor's hydraulic flow rate.

Q5. Where can I source replacement parts for the pickup mechanism if I am located in Western Australia?

A5. We have established a streamlined logistics network. Common wear parts like pickup teeth are stocked regionally, or can be air-freighted directly from our factory within 5-7 business days.

Q6. How does the net binding system compare to twine binding in terms of bale integrity and speed?

A6. Net binding is significantly faster (10-15 seconds/bale) than twine, increasing hourly throughput. It also provides better weather protection and shape retention for transport.

Q7. What is the warranty period for the main gearbox and structural components for international buyers?

A7. We offer a standard 12-month international warranty on the main gearbox and frame, with online technical support and video guidance for troubleshooting and repairs.

Q8. Can the 9YG-2.24D Round Baler handle large volumes of straw or silage?

A8: Yes, the 9YG-2.24D Round Baler is capable of handling large volumes of straw, silage, and other fibrous materials. Crops that can be baled include wheat, rice, cotton, pasture, corn silage, alfalfa, sugarcane, and reeds.

Q9: Is the 9YG-2.24D Round Baler suitable for use in challenging terrain and small fields?

A9: Yes, the baler is well-suited for small fields and difficult terrain. It is equipped with a double universal joint for better maneuverability and smoother operation during headland turns. This feature helps prevent PTO disengagement, which is common in tight, irregular field conditions, ensuring continuous operation without disruptions.

Q10: What makes the 9YG-2.24D Round Baler more energy-efficient compared to other balers?

A10: The 9YG-2.24D Round Baler achieves superior energy efficiency through its axial flow semi-forced feeding mechanism and regenerative hydraulic system. These systems reduce the need for additional power during operation, and the heavy-duty 20A chains distribute torque evenly, reducing strain on the machine and lowering fuel consumption while maintaining high throughput.

*면책 조항: 위에 언급된 다른 브랜드명은 예시 목적으로만 제공됩니다. 당사는 해당 브랜드명이 표시된 정품 제품이나 장비를 판매하지 않습니다.

편집자: PXY