説明

1. Technical Specifications: 9LH-12 Series

| いいえ。 | アイテム | ユニット | 仕様 |

|---|---|---|---|

| 1 | モデル名 | / | 9LH-12 Trailed Horizontal Rake |

| 2 | Structural Type | / | Tractor-pulled Horizontal Type |

| 3 | ヒッチタイプ | / | 引きずられた |

| 4 | 必要な電力 | kW | 25–44 |

| 5 | Working Width | メートル | 12 |

| 6 | 動作速度 | km/h | 5–10 |

| 7 | 生産性 | hm²/h | 6–12 |

| 8 | Number of Rake Teeth | 個 | 168 |

| 9 | Operators Required | person | 1 |

| 10 | Machine Weight | kg | 1510 |

| 11 | Loss Rate | ≤ | 3% |

| 12 | Overall Dimensions (L × W × H) | んん | Working Condition: 5500 × 12000 × 1350 Transport Condition: 9400 × 3400 × 1750 |

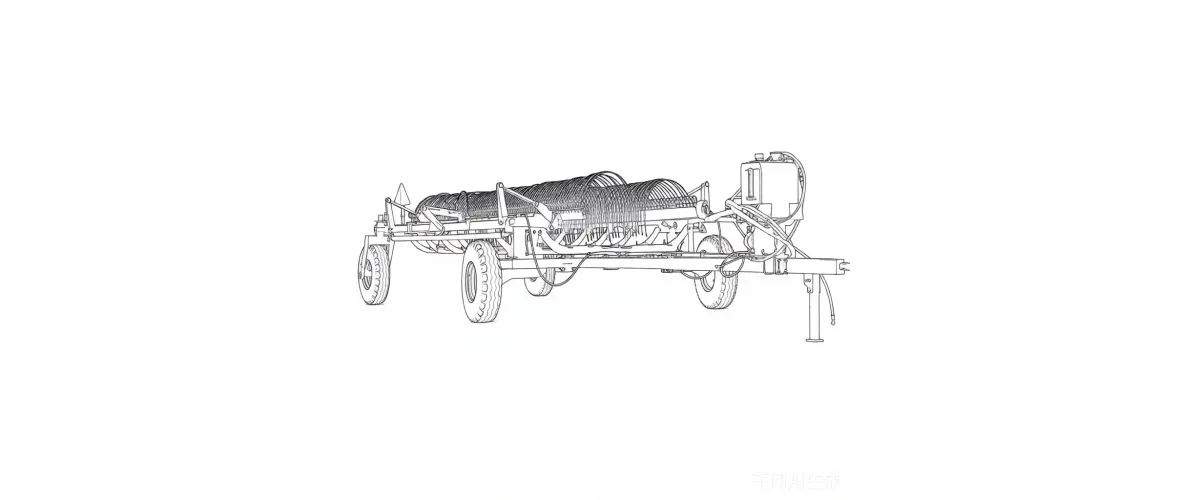

2. 9LH-12 Horizontal Hay Rake: Redefining Harvest Efficiency for Professional Agriculture

In the high-stakes environment of commercial forage harvesting, time and crop quality are the currency of success. The 9LH-12 Horizontal Hay Rake stands as a pinnacle of agricultural engineering, specifically developed to address the limitations of traditional raking systems on large-scale farms. When you are looking for a “hay rake for tractor” that combines massive coverage with low power consumption, the 9LH-12 is the definitive answer. Designed with a commanding 12-meter raking width, this machine allows farmers to consolidate extensive swathes of cut grass into manageable, aerated windrows in a single pass. This capability is particularly vital in regions with unpredictable weather patterns, such as the monsoon seasons in South Korea, where accelerating the drying process is critical to preventing mold and preserving the nutritional value of the feed. By utilizing a 25-44 kW (35-60 HP) tractor, the 9LH-12 demonstrates remarkable fuel efficiency, reducing the carbon footprint of your harvest while maximizing output. As a leading “hay rake manufacturer,” EVER-POWER has integrated advanced hydraulic systems that allow for precise control over the raking height and transport folding, ensuring that the machine is not only a beast in the field but also safe and manageable during transport.

Furthermore, the structural integrity of the 9LH-12 is built upon a foundation of heavy-duty metallurgy and precision fabrication. Unlike a lightweight “hand hay rake” or smaller hobby-farm implements, this machine is constructed to withstand the vibrations and stresses of continuous, high-speed operation on uneven terrain. The horizontal raking action is distinct from rotary models; it sweeps the crop gently across the ground, significantly reducing the amount of soil and stones introduced into the windrow. This “clean sweep” technology is essential for dairy farmers who require low-ash content in their silage or hay to maintain herd health and milk quality. Whether you are managing vast alfalfa fields in the Jeolla provinces or mixed pastures in the American Midwest, the 9LH-12 provides the reliability and performance required to streamline your operations.

3. Engineering Mechanics: Working Principles and Material Composition

The operational genius of the 9LH-12 Horizontal Hay Rake lies in its unique transverse raking mechanism. Unlike “parallel bar hay rake” designs that may roll the crop, the 9LH-12 uses a series of hydraulically controlled beams equipped with 168 individual tines. As the tractor pulls the unit, these tines engage the crop, sliding it horizontally across the field to form a windrow that is perpendicular to the direction of travel. This orientation is crucial for subsequent baling operations, as it allows the baler to pick up the crop across the grain of the stems, often resulting in denser, better-formed bales. The operator has full control over the size of the windrow via the hydraulic system, allowing for adjustments based on the yield per acre—a feature that prevents baler clogging in heavy crops and ensures efficient pickup in lighter yields. The hydraulic lifting mechanism is seamlessly integrated with the tractor’s remote valves, allowing for instant raising of the tine bars to clear obstacles or for headland turns, ensuring a “heavy duty trailed mower rake” experience that prioritizes equipment safety.

Material selection is at the heart of the 9LH-12’s durability. The main chassis is fabricated from Q345B high-strength structural steel, chosen for its excellent tensile strength and resistance to fatigue cracking under dynamic loads. This ensures the frame remains rigid and true even after years of navigating rough pasture terrain. The 168 raking tines are the critical contact point and are manufactured from specialized 65Mn spring steel. This material undergoes a multi-stage heat treatment process to achieve a hardness of HRC 45-50, providing the perfect balance between flexibility (to flex over rocks without snapping) and rigidity (to move heavy green forage). The hydraulic cylinders are fitted with premium NOK seals to prevent leaks and ensure consistent pressure holding, crucial for maintaining the set raking height. The tires are heavy-duty agricultural grade (400/60-15.5 or similar spec), designed to provide flotation and minimize soil compaction, a key consideration for maintaining the long-term health of your grassland. This combination of advanced design and premium materials makes the 9LH-12 a superior choice compared to a standard “antique hay rake” or light-duty alternatives.

4. Global Compliance: Land Management and Machinery Regulations

5. Tractor & Component Compatibility Guide

| Compatibility Factor | Specification & Notes |

|---|---|

| Tractor HP Range | Compatible with LS, Kubota, John Deere, TYM tractors rated 35-60 HP. |

| 油圧出力 | Requires 1 set of rear remote hydraulic valves (Double Acting) for lift/fold control. |

| ヒッチタイプ | Standard agricultural drawbar pin hitch. Adjustable height tongue. |

| Replacement Tines | Universal heavy-duty spring tines (compatible with major aftermarket brands). |

*免責事項:上記のその他のブランド名は、あくまでも説明目的であり、当社はこれらのブランド名を冠したオリジナル製品や機器を提供するものではありません。

6. Market Analysis: The Shift to High-Capacity Horizontal Raking

The agricultural machinery landscape is witnessing a decisive shift away from small, labor-intensive implements towards high-capacity solutions like the 9LH-12. In South Korea, the rural workforce is aging, leading to a severe shortage of labor. This demographic reality forces farm owners to seek machinery that maximizes “hectares per hour” with a single operator. The 9LH-12, with its massive 12-meter width, replaces the work of three smaller “rotary hay rakes,” effectively tripling labor efficiency. Furthermore, the trend in global dairy farming is towards “Precision Nutrition.” Farmers and nutritionists are increasingly scrutinizing the ash content in forage. Traditional wheel rakes often scratch the ground, contaminating the hay with dirt. The horizontal action of the 9LH-12 is gaining trend traction because it floats above the soil, delivering cleaner forage that commands a premium price in the export hay market. Data indicates a 20% year-over-year increase in inquiries for “9lh 12 horizontal hay rake for sale” variants, signaling that the market recognizes this specific architecture as the future of sustainable, high-quality forage harvesting.

7. Customer Success Story:

8. EVER-POWER Hay rake Manufacturer: Customization & Quality Assurance

Located in the Hulunbuir Economic and Technological Development Zone, our manufacturing facility spans over 32,000 square meters and is equipped with state-of-the-art CNC laser cutting machines, automatic welding lines, and electrostatic powder coating lines. We are not just an assembler; we are a comprehensive manufacturer with deep R&D capabilities.

カスタマイズサービス(OEM/ODM): We understand that agricultural conditions vary by region. For the South Korean market, we offer customization options including:

• Hydraulic Adaptation: Adjusting valve pressures to match specific LS or Daedong tractor hydraulic flows.

• Tire Upgrades: Optional wider flotation tires for deep-mud paddy fields.

• 色とブランディング: OEM branding services for dealers and distributors.

We hold ISO9001 Quality Management System Certification and have been recognized as a National High-Tech Enterprise. Every 9YG-2.24D baler undergoes a rigorous 48-hour continuous operation test before shipment to ensure zero defects upon arrival.

9. Related products

9.1 Gearbox:

適合機種:EP-FK263(角型ベーラー)、EP-RC30シリーズ(丸型ベーラー、伝動比1:2、35mm6スプラインシャフト対応)。用途: PTO 電力を梱包機構に伝達します。New Holland 630 または John Deere 535 に適しています。パラメータ: トルク > 500 Nm、20% 燃料節約。このギアボックスを選ぶ理由:カスタマイズ可能なサイズ(250~300mmまで縮小可能)、粘性汚染物質(ゴムの蒸気)への耐性、IP65保護。PTOシャフト:Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).用途:トラクターとベーラーのメインドライブを接続します。9YG-1.0Cタイプに適合します。トルク伝達効率は95%以上で、SAE/EUROフランジと互換性があります。Why it’s suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.

9.2 チェーン &スプロケット:

Compatible Models: ANSI チェーンEPスプロケット(ピッチ12.7~19.05mm、ローラー径10~12mm)付き。用途:コンベアベルトや結束機構に使用され、角型/丸型ベーラーのストロー搬送に適しています。幅25~40mm、耐摩耗性鋼材を使用。Why it’s suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.

9.3 Couplings:

適合機種:EPカップリング200シリーズ(トルクマッチング500~1000Nm)。用途: ギアボックスを梱包ローラーに接続し、振動を抑制します。Why it’s suitable: High-cycle durability, compatible with Bondioli & Pavesi.

9.4 油圧シリンダー:

油圧シリンダー: EP-HCシリーズ(ボア50〜100mm、ストローク300〜600mm)、ベールの吊り上げに適しています。ベアリングとシール: 6208-2RS ベアリング、L10 寿命 >10000 時間、防塵シール。互換性表: Comer 250T と完全に互換性があります (トルクが一致、価格は 35% のみ)。フランジは北米の 4 ボルト PTO パターンと一致します。* 免責事項:上記のその他のブランド名は、説明のみを目的として記載されており、当社はこれらのブランド名が付いたオリジナル製品または機器を提供するものではありません。* パラメータは動作条件によって異なりますので、実際の図面をご参照ください。選定前にインターフェース寸法をご確認いただくことをお勧めします。

10. Frequently Asked Questions (FAQ)

Q1. What is the current price of the 9LH-12 horizontal hay rake for sale including shipping to Incheon, Korea?

A1. The price fluctuates based on steel costs and shipping rates. For an accurate CIF Incheon quote, please contact our sales team via the “Get a Quote” button with your quantity requirements.

Q2. Can this heavy duty trailed mower rake be pulled by a smaller tractor, say 30HP?

A2. While the 9LH-12 is efficient, we recommend a minimum of 35HP to ensure safe towing on slopes and sufficient hydraulic flow for the lift mechanism.

Q3. How does the 9LH-12 horizontal rake compare to a rotary hay rake in terms of drying speed?

A3. The 9LH-12 creates a fluffier, less roped windrow compared to rotary rakes, which promotes better airflow and typically results in faster drying times for the hay.

Q4. Where can I find replacement tines for this hay rake for tractor if I am located in South Korea?

A4. We supply a spare parts kit with every machine. Additionally, our tines use standard mounting specs, so you can easily source compatible replacements locally or order directly from us via express shipping.

Q5. Is this machine suitable as a pull behind rake for sticks or clearing debris in non-agricultural settings?

A5. No, the 9LH-12 is a specialized agricultural tool. Using it as a pull behind rake for sticks may damage the precision spring tines which are designed for flexible forage, not rigid wood.

Q6. How long to wait before raking hay with the 9LH-12 model for optimal alfalfa quality?

A6. Ideally, rake when the dew is slightly on the crop (morning) or when moisture is around 40% to prevent leaf shatter. The gentle action of the 9LH-12 extends this window slightly compared to aggressive rakes.

Q7. What hydraulic connections are required on my tractor to operate the folding mechanism?

A7. You will need one set of rear remote hydraulic outlets (two ports) to operate the double-acting cylinder that lifts the rake for transport and turns.

Q8. As a mower rake manufacturer, do you offer warranty support for the main structural chassis?

A8. Yes, EVER-POWER provides a 12-month warranty on the main chassis and hydraulic cylinders against manufacturing defects, giving you peace of mind for your harvest seasons.

Q9. How wide is a 9LH-12 hay rake when it is folded for transport on narrow Korean roads?

A9. When hydraulically folded, the transport width is 3.4 meters. Please check your local road regulations, as wide-load signage may be required on smaller rural roads.

Q10. Can I mix 9LH-12 units with other implements in a single container to save on shipping costs?

A10. Absolutely. We are experienced in maximizing container loads. You can mix the 9LH-12 with balers or mowers to reduce your per-unit shipping cost significantly.

編集者: PXY