説明

1. Technical Specifications & Parameters

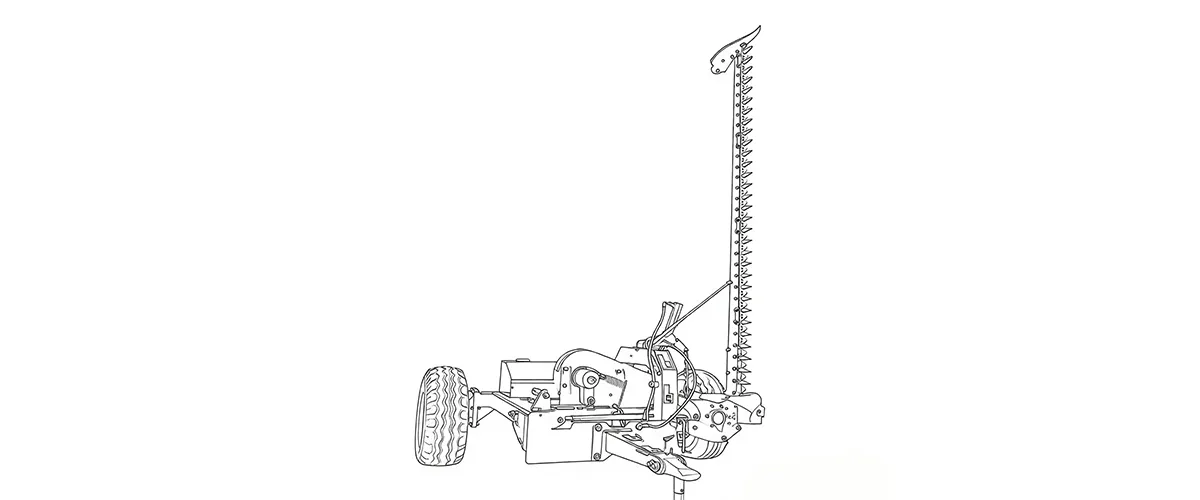

| いいえ。 | アイテム | ユニット | 仕様 |

|---|---|---|---|

| 1 | モデル名 | / | 9GD-2.5 Trailed Single Blade Mower Upgraded version |

| 2 | ヒッチタイプ | / | 引きずられた |

| 3 | Cutter Structure Type | / | Reciprocating |

| 4 | Cutting Width | メートル | 2.5 |

| 5 | Matching Power Range | kw | 15-35 |

| 6 | Working Speed Range | km/h | 6-10 |

| 7 | Number of Moving Blades | 個 | 34 |

| 8 | Dimensions (Length × Width × Height) | んん | 2000×4300×950 |

| 10 | Power Output Shaft Speed | 回転数 | 540 |

| 11 | Average Cutting Height | んん | 50-70 |

| 12 | 生産性 | hm2/h | 2.0-3.0 |

| 13 | Number of Operators | (persons) | 1 |

| 14 | Structure Weight | kg | 490 |

2. Advanced Cutting Technology & Application Scenarios

3. Global Regulatory Standards & Compliance

4. Market Trend Analysis: The Future of Forage Harvesting

The global agricultural sector is witnessing a significant shift towards “precision harvesting.” In South Korea, where the aging rural population is creating a labor shortage, there is an increasing demand for machinery that offers high hectares-per-hour (ha/h) efficiency with minimal maintenance. The 9GD-2.5 Towed Single-Blade Lawn Mower for sale caters to this trend by providing a “set and forget” mechanical reliability. We are also seeing a movement towards offset mowers that minimize soil compaction by keeping the tractor on already-cut paths. Industry data suggests that the market for sickle-bar mowers is projected to grow by 4.2% annually as farmers recognize the superior dry-down speed of reciprocating-cut forage compared to rotary-cut crops.

5. Component Compatibility & Brand Comparison

| Brand/Component | Compatibility Status | Key Benefit for Korean Market |

|---|---|---|

| LS Mtron / Daedong Tractors | Fully Compatible | Direct fit for standard Category 1 & 2 hitches. |

| Jiujia 65Mn Blades | OEM Standard | Higher wear resistance than generic carbon steel. |

| Walterscheid PTO Shafts | Compatible | Enhanced safety with world-class torque protection. |

| SKF / NSK Bearings | Standardized | Easy local procurement for maintenance in Korea. |

6. Customer Success Case Study:

Client 1 Profile: South Korea, Gyeonggi-do Forage Producer

Customer Reviews:

“As a commercial forage producer in Gyeonggi-do, I rely on the 9GD-2.5 Towed Mower to maintain my alfalfa fields. The 3.2-meter cutting width means I can get through large fields quickly, which is critical during the short harvest windows. The adjustable rollers ensure that I can condition my crops perfectly, even in the wet, dense fields we have here. The machine has definitely saved us time and improved our hay quality, leading to better prices at the market.”

Client 2 Profile: United States, Midwest Alfalfa Farmer

Customer Reviews:

“Here in the Midwest, where the weather can be unpredictable, the 9GD-2.5 Mower is a game-changer. The adjustable conditioning rollers are fantastic for getting the perfect drying conditions, and the sturdy frame handles our rocky soils well. We’ve seen a 30% reduction in drying time compared to other mowers we’ve used in the past, which has greatly improved our overall productivity.”

Client 3 Profile: Australia, Queensland Livestock Farmer

Customer Reviews:

“In Queensland, we deal with a lot of heavy clay and uneven terrain. The 9GD-2.5 Mower’s towed design provides superior stability compared to mounted models. This makes it much easier to navigate the slopes and still get a uniform cut. The 540 RPM PTO works perfectly with my tractor, and I’ve been impressed with how the mower handles our challenging conditions without compromising on performance.”

Client 4 Profile: Brazil, São Paulo Forage Grower

Customer Reviews:

“We’ve been using the 9GD-2.5 Mower for over a year now on our large-scale forage operation in São Paulo. The machine’s high cutting width and robust construction make it perfect for our humid conditions, and it handles our tall grasses and dense crops with ease. The 65Mn manganese steel blades last much longer than the standard carbon steel blades we used to have, and the increased productivity has really helped us keep up with demand.”

7. EVER-POWER Factory: Customization & Quality Assurance

Located in the Hulunbuir Economic and Technological Development Zone, our manufacturing facility spans over 32,000 square meters and is equipped with state-of-the-art CNC laser cutting machines, automatic welding lines, and electrostatic powder coating lines. We are not just an assembler; we are a comprehensive manufacturer with deep R&D capabilities.

カスタマイズサービス(OEM/ODM): We understand that agricultural conditions vary by region. For the South Korean market, we offer customization options including:

• Hydraulic Adaptation: Adjusting valve pressures to match specific LS or Daedong tractor hydraulic flows.

• Tire Upgrades: Optional wider flotation tires for deep-mud paddy fields.

• 色とブランディング: OEM branding services for dealers and distributors.

We hold ISO9001 Quality Management System Certification and have been recognized as a National High-Tech Enterprise. Every 9YG-2.24D baler undergoes a rigorous 48-hour continuous operation test before shipment to ensure zero defects upon arrival.

8. Related products

8.1 Gearbox:

適合機種:EP-FK263(角型ベーラー)、EP-RC30シリーズ(丸型ベーラー、伝動比1:2、35mm6スプラインシャフト対応)。用途: PTO 電力を梱包機構に伝達します。New Holland 630 または John Deere 535 に適しています。パラメータ: トルク > 500 Nm、20% 燃料節約。このギアボックスを選ぶ理由:カスタマイズ可能なサイズ(250~300mmまで縮小可能)、粘性汚染物質(ゴムの蒸気)への耐性、IP65保護。PTOシャフト:Compatible Models: EP-PTO series (1-3/8″ Z6 spline, adjustable length 600-1200mm).用途:トラクターとベーラーのメインドライブを接続します。9YG-1.0Cタイプに適合します。トルク伝達効率は95%以上で、SAE/EUROフランジと互換性があります。Why it’s suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.

8.2 チェーン &スプロケット:

Compatible Models: ANSI チェーンEPスプロケット(ピッチ12.7~19.05mm、ローラー径10~12mm)付き。用途:コンベアベルトや結束機構に使用され、角型/丸型ベーラーのストロー搬送に適しています。幅25~40mm、耐摩耗性鋼材を使用。Why it’s suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.

8.3 Couplings:

適合機種:EPカップリング200シリーズ(トルクマッチング500~1000Nm)。用途: ギアボックスを梱包ローラーに接続し、振動を抑制します。Why it’s suitable: High-cycle durability, compatible with Bondioli & Pavesi.

8.4 油圧シリンダー:

油圧シリンダー: EP-HCシリーズ(ボア50〜100mm、ストローク300〜600mm)、ベールの吊り上げに適しています。ベアリングとシール: 6208-2RS ベアリング、L10 寿命 >10000 時間、防塵シール。互換性表: Comer 250T と完全に互換性があります (トルクが一致、価格は 35% のみ)。フランジは北米の 4 ボルト PTO パターンと一致します。* 免責事項:上記のその他のブランド名は、説明のみを目的として記載されており、当社はこれらのブランド名が付いたオリジナル製品または機器を提供するものではありません。* パラメータは動作条件によって異なりますので、実際の図面をご参照ください。選定前にインターフェース寸法をご確認いただくことをお勧めします。

9. Agricultural Professional FAQ

Q1. How much does a professional 9GD-2.5 Towed Single-Blade Lawn Mower cost for farms in Gyeonggi-do?

A1. The **price** of the 9GD-2.5 depends on specific customization and shipping logistics to Busan or Incheon. Generally, as a factory-direct **supplier**, we offer the most competitive commercial **quotes** for high-volume orders in South Korea.

Q2. Where can I find a reliable Jiujia machinery supplier for agricultural mower parts near Seoul?

A2. Jiujia provides a direct distribution network across Korea. You can contact our **Jiujia machinery Korea** service center or request a local **supplier** list via our website to ensure you receive genuine parts and professional maintenance.

Q3. What is the recommended engine power needed to operate the towed single-blade mower efficiently in heavy grass?

A3. For the 9GD-2.5 model, we recommend a tractor with at least 20 HP. However, for dense or wet forage common in the Gangwon-do highlands, a 40-50 HP tractor will provide the reserve torque required for a consistent cutting speed.

Q4. How does the reciprocating blade technology help with high-yield alfalfa harvesting compared to standard rotary cutters?

A4. Reciprocating mowers like our **Jiujia mower** provide a clean shear cut. This prevents the “bruising” and leaf loss associated with rotary slashers, resulting in higher nutritional value and faster regrowth of the alfalfa crop.

Q5. Which type of maintenance is required for the 9GD-2.5 Towed Single-Blade Lawn Mower during the harvest season?

A5. Maintenance is straightforward: ensure the sickle bar is lubricated daily, check the blade sharpness every 50 hours of operation, and verify that the safety trip mechanism is clear of debris. Most parts are standardized for quick replacement.

Q6. Why should professional land cooperatives in Korea choose Jiujia as their primary agricultural mower manufacturer?

A6. Jiujia is a specialized **manufacturer** with 20+ years of history. We offer upgraded editions with reinforced frames and 65Mn manganese steel blades, specifically designed to withstand the rocky and demanding soil conditions found in South Korea.

Q7. How does the machine handle rocky terrain or hidden obstacles during high-speed field operations?

A7. The 9GD-2.5 (Upgraded Edition) features an automatic safety trip mechanism. If the blade hits a significant obstacle, the bar will swing back instantly, preventing structural damage to the frame or the tractor’s PTO shaft.

Q8. When is the best time to replace the manganese steel blades on a used Jiujia machinery mower?

A8. Blades should be replaced when they show signs of excessive thinning or if they cannot be sharpened back to a clean edge. Using original Jiujia blades ensures perfect balance and prevents vibration damage to the crank-link system.

Q9. What are the shipping logistics for importing agricultural machinery from Jiujia to the South Korean port of Busan?

A9. We offer comprehensive EXW, FOB, and CIF shipping terms. Most orders for the 9GD-2.5 series are containerized and shipped directly to Busan or Incheon, with full documentation provided for local customs clearance and tax benefits.

Q10. How do I adjust the cutting height of the 9GD-2.5 mower for different crop types?

A10. The cutting height is easily adjustable via the mechanical slide shoes located at each end of the sickle bar. By changing the shoe angle, you can set the cut from as low as 3cm for lawns to 8cm for tall forage.

編集者: PXY

*免責事項:上記のその他のブランド名は、あくまでも説明目的であり、当社はこれらのブランド名を冠したオリジナル製品や機器を提供するものではありません。