EP-9YG-2.24D ラウンドベーラー S9000 クラシック

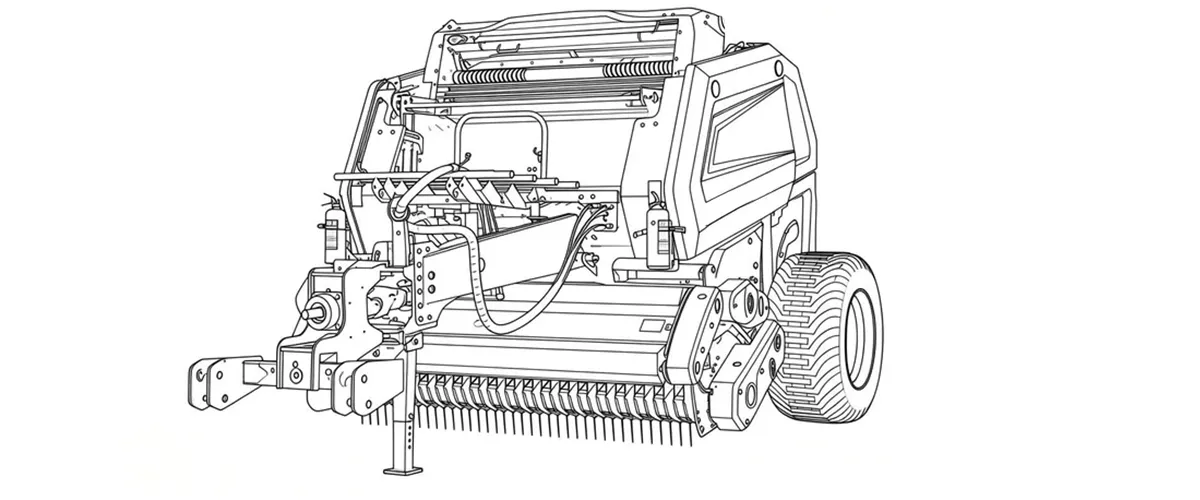

The 9YG-2.24D Round Baler (S9000 Classic) is a high-performance, durable, and energy-efficient solution for efficient crop residue management. Designed for various crops such as straw, silage, and sugarcane, this baler features a robust roller compression system, advanced feeding mechanism, and superior maneuverability. Ideal for optimizing storage and transportation, it meets global environmental regulations and offers a reliable solution for large-scale agricultural operations.

1. EVER POWER Exclusive Specifications and Parameters S9000 Classic

| Parameter | 仕様 |

|---|---|

| モデル名 | 9YG-2.24D Round Baler (S9000 Classic) |

| ヒッチタイプ | Traction Type (Drawbar) |

| ピックアップ幅 | 2240 mm |

| 圧縮室タイプ | Roller Type (18 Rollers) |

| Bale Size (Diameter x Width) | Φ1300 x 1400 mm |

| ベール密度 | 100 - 200 kg/m³ |

| 生産性 | 40 - 100 bales/hour |

| Matching Power | 55 - 100 kW (approx. 75 - 135 HP) |

| 構造重量 | 4312 kg |

| PTO速度 | 720 r/min |

| Working Dimensions (L x W x H) | 4470 x 3010 x 2370 mm |

| 製本方法 | Net Binding (Automatic) |

| Hydraulic Connection | H-Type Ferrule Joints (High Pressure) |

2. Redefining Harvest Efficiency: The S9000 Classic

3. Advantages of the 9YG-2.24D Round Baler (S9000 Classic)

3.1. Advanced Feeding Mechanism:

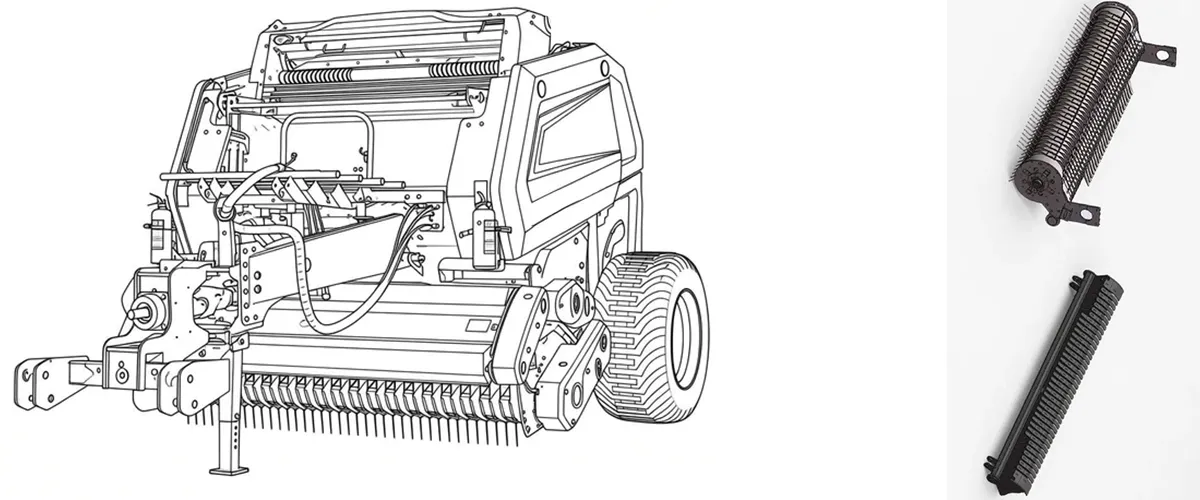

The 9YG-2.24D S9000 Classic employs an axial flow semi-forced feeding system. Unlike traditional models with cam tracks and retaining rings, this system significantly reduces power consumption while improving the feeding rate. It decreases the likelihood of material blockage, enhancing operational efficiency .

3.2. High Bale Density:

The round baler is equipped with 18 heavy-duty rollers, ensuring a consistent compression force that allows it to create high-density bales. This is particularly advantageous for optimizing transport logistics and storage space .

3.3. Superior Durability and Efficiency:

The dual-side heavy-duty 20A chains increase the baler's compression force, resulting in stronger and denser bales. The addition of a buffer cylinder in the rear chamber mitigates vibration during the closing cycle, enhancing the baler's lifespan and reducing wear .

3.4. Optimized Hydraulic System:

The hydraulic system features H-type ferrule joints, which increase pressure tolerance and speed up the opening and closing cycle times. Additionally, the use of these high-pressure components ensures zero leakage, aligning with environmental protection standards .

3.5. Flexible Operation:

The baler can handle a wide range of crop residues such as corn, wheat, soybeans, and pasture grass. It also supports a wide pickup width of 2240mm, ensuring efficiency during the collection phase .

3.6. Adaptability in Challenging Terrains:

The traction device features a newly designed double universal joint, allowing for better maneuverability in fields with tight turns. This mechanism also helps maintain a smooth operation during field headlands without disengaging the PTO, which decreases operator fatigue.

3.7. Improved Stability for Various Field Conditions:

The baler's structural stability is enhanced by the double-sided drive design in the rear chamber, which prevents the failure of the drive or axle during high-torque operations, especially in uneven field conditions .

4. Environmental Compliance & Global Agricultural Regulations

The shift from traditional field burning to biomass recovery is driven by increasingly stringent global environmental regulations. While industries like chemical processing focus on Regenerative Thermal Oxidizers (RTOs) to handle hazardous exhaust, the agricultural sector faces parallel mandates regarding Particulate Matter (PM2.5) reduction and Carbon Footprint management. In Australia, the National Environment Protection (Ambient Air Quality) Measure and various state-level EPA guidelines strictly regulate agricultural burning to prevent smoke haze and protect public health. Similarly, strict directives in the European Union (under the Common Agricultural Policy) and China (Law on the Prevention and Control of Atmospheric Pollution) have effectively banned straw burning, mandating mechanical harvesting and baling as the primary solution.

The 9YG-2.24D Round Baler serves as a critical tool for compliance with these legislative frameworks. By efficiently converting loose straw and residue into high-density bales, farmers can transform what was once a waste product requiring incineration into a valuable resource for biomass energy, animal feed, or paper manufacturing. Furthermore, the machine is designed in accordance with rigorous safety standards, including ISO 4254-1 (Agricultural machinery safety) and relevant Australian Standards for machinery guarding and hydraulic safety. The use of H-type ferrule joints in the hydraulic system ensures zero leakage, preventing soil contamination, which aligns with the Environment Protection and Biodiversity Conservation Act.

5. Global Trends in Forage Harvesting Technology

Application in Bazil

In Brazil, the utilization of biomass energy has become crucial in driving sustainable agriculture and green energy development. As a leading global agricultural machinery manufacturer, Ever Power provides efficient solutions for the Brazilian market, particularly in sugarcane residue management. Our 9YG-2.24D baler is specifically designed for efficiently baling sugarcane residue, compressing it into high-density round bales for easy transportation and storage.These baled sugarcane residues can not only be used as raw materials for animal feed but also converted into biomass energy, becoming an important alternative energy source. With the continuous development of biomass utilization technology, Ever Power's balers are helping farmers improve the recycling rate of sugarcane residue, reduce environmental pollution, and lay a solid foundation for renewable energy production. With Ever Power balers, Brazilian agricultural enterprises can not only reduce production costs and improve the overall utilization rate of crops but also meet the country's strict requirements for green energy and environmental regulations. Whether it's improving land use efficiency or achieving zero-waste sustainable development, Ever Power provides strong technical support to help Brazilian agriculture move towards a more environmentally friendly and efficient future.

6. Customer Success Story:

“The S9000 Classic has improved our harvesting efficiency. Our productivity has increased significantly, and the bale density is much higher. The roller-type compression chamber ensures we can handle many different types of crops, which I really appreciate. I highly recommend this machine!”

— John, Farm Manager, Queensland, Australia

“As a family business, we rely on machinery that can handle the challenges of different crops. The advantage of the 9YG-2.24D round baler is that it can handle both dry hay and high-moisture silage, making it an indispensable part of our operation. The net wrapping system has greatly improved efficiency. And the classic model is even more reliable.”— Sarah, Victoria, Australia

“We have been using the S9000 for several seasons now, and its performance has been consistently reliable. The compact design reduces maintenance requirements, making our operations smoother. Furthermore, whenever we have encountered issues requiring parts or technical support, Ever Power's customer service has been excellent, and the after-sales service is fantastic.”— Daniel, Equipment Manager, Northern Territory, Australia

“It's robust and durable, and performs perfectly even in our sandy soil conditions. The long-lasting chain system was a key factor in our purchase decision.”— Mark, Operations Supervisor, New South Wales, Australia

“Integrating Ever Power's RTO technology into our baling process was one of the best decisions I've ever made. This baler has also far exceeded our expectations in terms of speed.”— Leo, Farmer, Melbourne, Australia

7. Compatibility & Performance Comparison

| Feature | EP 9YG-2.24D (S9000) | Standard Competitor Baler | Advantage |

|---|---|---|---|

| **Transmission** | Double-sided 20A Heavy Duty Chain | Single-sided standard chain | Balanced load, higher torque, longer lifespan. |

| **Traction Device** | Double Universal Joint + Safety Torque | Standard PTO Shaft | Smoother turning in small fields; overload protection. |

| **Hydraulic Fittings** | H-Type Ferrule (High Pressure) | Standard O-Ring Seal | Zero leakage, faster open/close cycle times. |

| **Pickup Mechanism** | Axial Flow (No Cam Track) | Cam Track System | Fewer moving parts, less maintenance, higher speed. |

| **Rear Chamber** | Equipped with Buffer Cylinder | Mechanical Stop | Reduces vibration shock, protects frame integrity. |

8. Application Scenarios

Case Study 1: Application in Large-Scale Hay Export Farms in the United StatesIn large-scale hay export farms in the United States, balers significantly improved bale density and transportation efficiency, meeting the demand for over 100,000 tons of hay annually. The EP-FK263 square baler, with a torque range of 500-2000 Nm and compatible with John Deere interface standards (SAE flange), achieved bale densities >200 kg/m³ and 20% fuel savings in applications in California or Texas farms. According to USDA data, US hay exports reached 1.5 million tons in 2024, driving the demand for mechanization.

Case Study 2: Application in China's Straw Comprehensive Utilization Industrial ParksIn China's straw comprehensive utilization industrial parks, balers optimized the biomass energy supply chain, processing over 500,000 tons of straw annually. The 9YG-1.0C round baler, with a power range of 30-120 HP and a speed ratio of 1:2-1:4, compatible with Kubota spline shafts (35mm 6-key), achieved a bale diameter of 1.0m and a 30% increase in efficiency in parks in Shandong and Henan provinces. According to the National Bureau of Statistics, China's annual straw production is 800 million tons, driving mechanization subsidy policies (agricultural machinery purchase subsidies >20%).

Case Study 3: Application in Brazilian Sugarcane Residue Energy FarmsIn Brazilian sugarcane residue energy farms, balers improved the efficiency of the bioethanol supply chain, with an annual output of over 300,000 tons of residue. With a power range of 20-100 HP and a speed ratio of 1:1-1:5, applications in São Paulo state achieved uniform bale density and compatibility with Case IH interfaces. Data from the Brazilian Ministry of Agriculture shows that Brazil is the world's largest producer of sugarcane (790 million tons/year), driving the demand for residue recycling.

Case Study 4: Application in German Precision Agriculture Organic FarmsIn German precision agriculture organic farms, balers ensured compliance with EU organic standards, processing over 100,000 tons of organic straw annually. The EP-PTO series gearbox, with DIN 6 precision and a speed ratio of 1:1.5-1:3, achieved precise baling in applications in Bavaria. EU statistics show that organic farmland accounts for 20% of Germany's total farmland, driving the demand for efficient machinery.

Case 5: Application in a Canadian Grain Straw Biomass Power PlantIn the Canadian grain straw biomass power plant, balers support the renewable energy chain, supplying >250,000 tons of straw annually. EP-Coupling 200 series couplings are used, with a torque of 500-1000 Nm, applied in Ontario, providing vibration damping. Data from the Canadian Ministry of Agriculture shows a CAGR of 6% for biomass demand.

Case 6: Large-Scale Wheat Straw Harvesting Application in RussiaIn large-scale wheat straw harvesting in Russia, balers improved export efficiency, with an annual output exceeding 400,000 tons. EP-Sprocket sprockets are used, with a pitch of 12.7mm, applied in Rostov Oblast, enabling cold-resistant operation. A report from the Russian Ministry of Agriculture shows that Russia is the world's third-largest wheat producer (80 million tons/year).

Case 7: Application in a South African Corn Stover Feed Processing PlantIn a South African corn stover feed processing plant, balers optimized the livestock supply chain, processing >180,000 tons annually. EP-HC hydraulic cylinders are used, with a bore diameter of 50-100mm, applied in Gauteng province, improving efficiency. Data from the South African Ministry of Agriculture shows a corn production of 12 million tons/year, driving feed demand.

Case 8: Application in a Thai Rice Straw Biofuel FarmIn a Thai rice straw biofuel farm, balers facilitated the renewable energy transition, with an annual rice straw volume of >120,000 tons. EP-PTO shafts are used, with a length of 600-1200mm, applied in the Central Plains, providing waterproof transmission. A report from the Thai Ministry of Agriculture shows a rice production of 20 million tons/year, with an 8% growth in biofuel demand.

9. Manufacturing Excellence & Customization Services

9.1. 艦隊に合わせた特定の配色を要求する(赤、緑、またはカスタム)

9.2. 岩場に適した強化シャーシ

9.3. さまざまなトラクター ブランド (John Deere、Case IH、New Holland、Kubota) 用のヒッチ アダプターについては、当社の R&D センターがお客様のニーズにお応えします。

9.4. ピックアップシステムを標準のスプリング歯とトウモロコシの茎用のハンマー爪の間で交換できる当社の能力は、汎用性への当社のコミットメントを証明しています。すべてのユニットは工場出荷前に厳格なテストを実施し、ISO 9001品質基準を満たしていることを確認しています。

証明書と栄誉:

· ISO 9001認証

· 国家ハイテク企業証明書

・自社輸出入業務権

· CE認証

10. 交換可能な部品

10.1 ギアボックス:

10.2 チェーン &スプロケット:

10.3 カップリング:

10.4 油圧シリンダー:

11. よくある質問

Q1. S9000のダブルユニバーサルジョイントドライブシャフトは、狭いフィールドや不規則なフィールドでの操作にどのようなメリットをもたらしますか?

A1. 特殊なダブルユニバーサルジョイントにより、PTOを解除することなく、より狭い旋回角度を実現し、ドライブラインの固着を防ぎ、枕地旋回時のオペレーターの疲労を大幅に軽減します。

Q2. 他の梱包機で使用されている標準チェーンと比較して、20A高耐久性チェーンの予想寿命はどのくらいですか?

A2. 当社の強化20Aチェーンは、30%の高トルク負荷に耐えるように設計されており、高密度梱包条件下では標準チェーンよりも2~3シーズン長く使用できます。

Q3. この梱包機は水分の多いサイレージ作物にも対応できますか?それとも乾燥した干し草やわら専用ですか?

A3. はい、ローラー式圧縮チャンバーはサイレージに最適です。発酵に適した嫌気条件を確保するために、密度設定を調整し、高品質のネットラップを使用することをお勧めします。

Q4. 9YG-2.24Dは、油圧出力が低い可能性のある古いトラクターモデルと互換性がありますか?

A4. このユニットは最低55kW(75HP)の油圧を必要とします。H型ジョイントは高圧に対応しますが、システムは適応性があります。ご使用のトラクターの油圧流量については、当社の技術者にご相談ください。

Q5. 西オーストラリア州に住んでいる場合、ピックアップ機構の交換部品はどこで入手できますか?

A5. 効率的な物流ネットワークを構築しています。ピックアップ歯などの一般的な消耗部品は、地域在庫として保管するか、工場から5~7営業日以内に航空便で直接配送することも可能です。

Q6. ベールの完全性と速度の点で、ネット結束システムはより糸結束システムと比べてどうですか?

A6. ネット結束は、より糸結束に比べてはるかに速く(1ベールあたり10~15秒)、時間当たりの処理能力が向上します。また、輸送時の耐候性と形状保持性にも優れています。

Q7. 海外の購入者に対するメインギアボックスと構造部品の保証期間はどのくらいですか?

A7. メインギアボックスとフレームには標準で12ヶ月間の国際保証が付いており、トラブルシューティングと修理のためのオンラインテクニカルサポートとビデオガイダンスもご利用いただけます。

Q8. 9YG-2.24Dラウンドベーラーは大量のわらやサイレージを処理できますか?

A8: はい、9YG-2.24Dラウンドベーラーは、大量のわら、サイレージ、その他の繊維質材料を処理できます。ベールにできる作物には、小麦、米、綿花、牧草、トウモロコシサイレージ、アルファルファ、サトウキビ、アシなどがあります。

Q9: 9YG-2.24D ラウンドベーラーは、困難な地形や狭い畑での使用に適していますか?

A9: はい、このベーラーは狭い圃場や困難な地形に適しています。ダブルユニバーサルジョイントを搭載しているため、枕地旋回時の操縦性が向上し、スムーズな操作が可能です。この機能により、狭く不整地の圃場でよく見られるPTOの解除を防ぎ、中断のない連続運転を実現します。

Q10: 9YG-2.24D ラウンドベーラーは他のベーラーと比べてなぜエネルギー効率が良いのですか?

A10: 9YG-2.24Dラウンドベーラーは、軸流式半強制給送機構と回生油圧システムにより、優れたエネルギー効率を実現します。これらのシステムにより、運転中に必要な追加電力が削減され、高耐久性20Aチェーンがトルクを均等に分配することで、機械への負担を軽減し、高い処理能力を維持しながら燃料消費量を削減します。

*免責事項:上記のその他のブランド名は、あくまでも説明目的であり、当社はこれらのブランド名を冠したオリジナル製品や機器を提供するものではありません。

編集者: PXY