EP-9YG 2.24D ラウンドベーラー S9000 トランセンデンス

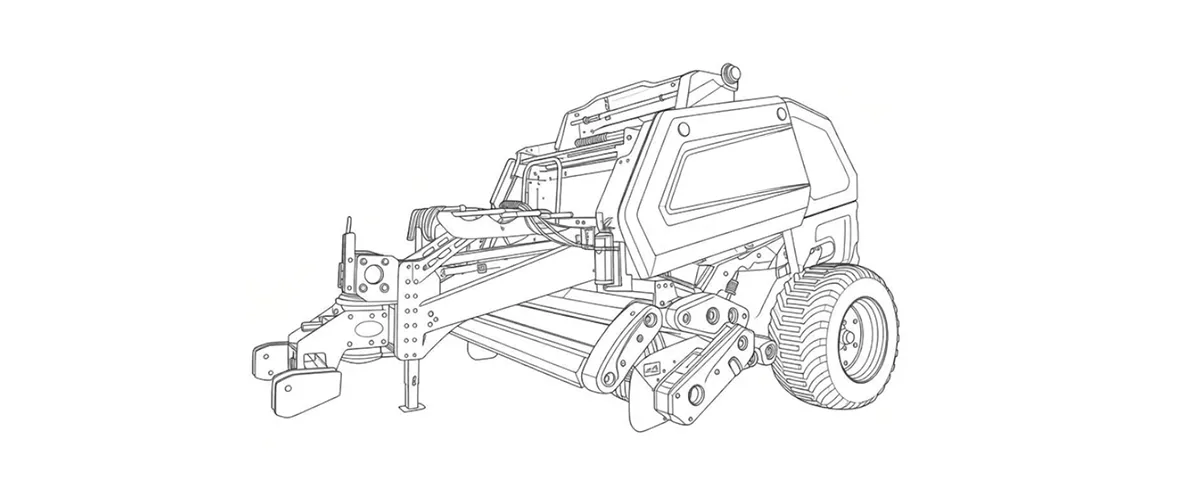

The 9YG-2.24D Round Baler (S9000 Super) is the most advanced model in its series, designed for high-efficiency agricultural harvesting.

This round baler features a wider pick-up width (2240mm) and a larger compression chamber diameter (φ1200mm), allowing it to handle larger volumes of crops and increase operational efficiency.

Compared to standard models on the market, the S9000 Super offers significant advantages in fuel consumption, ease of operation, and bale consistency. Additionally, it reduces maintenance costs while boosting work efficiency.

1. Technical Specifications (S9000 Transcendence)

| Parameter | Specification (S9000 Transcendence) |

|---|---|

| ピックアップ幅 | 2240 mm (2.24 m) |

| Chamber Type | Fixed Roller Type (18 Rollers) |

| Bale Size (Dia x Width) | Φ1300 × 1400 mm |

| ベール密度 | 100 - 200 kg/m³ (Bale weight ~500kg) |

| Binding System | 自動ネットラップ |

| Machine Weight | 4570 kg (Heavy Duty Structure) |

| 必要な電力 | 55 - 100 kW (75 - 135 HP) |

| 生産性 | 40 - 100 Bales / Hour |

| PTO速度 | 720 r/min (Customizable) |

| Dimensions (L x W x H) | 4600 × 3010 × 2370 mm |

*NOTE: Engineered for professional contractors and large-scale farms, the S9000 Transcendence offers superior weight and stability compared to the standard model, ensuring durability in the harshest harvesting conditions.

2.What is the EP-9YG 2.24D Round Baler S9000 Transcendence

The 9YG 2.24D Round Baler S9000 Transcendence is a high-performance baler designed to enhance efficiency in agricultural operations. Perfect for harvesting hay, straw, and other crops, this baler delivers optimal bale density and consistency, making it a great choice for large-scale farming.

Featuring a round bale feeder, it simplifies the baling process, reducing labor costs and improving productivity. The machine's advanced compression technology ensures that each round hay bale is tightly packed and easy to handle, whether you're preparing hay for livestock feed or storage. It is also compatible with round bale hay nets, ensuring your hay remains secure and protected from the elements.

3. Five Core Advantages of the EP-9YG 2.24D Round Baler S9000 Transcendence

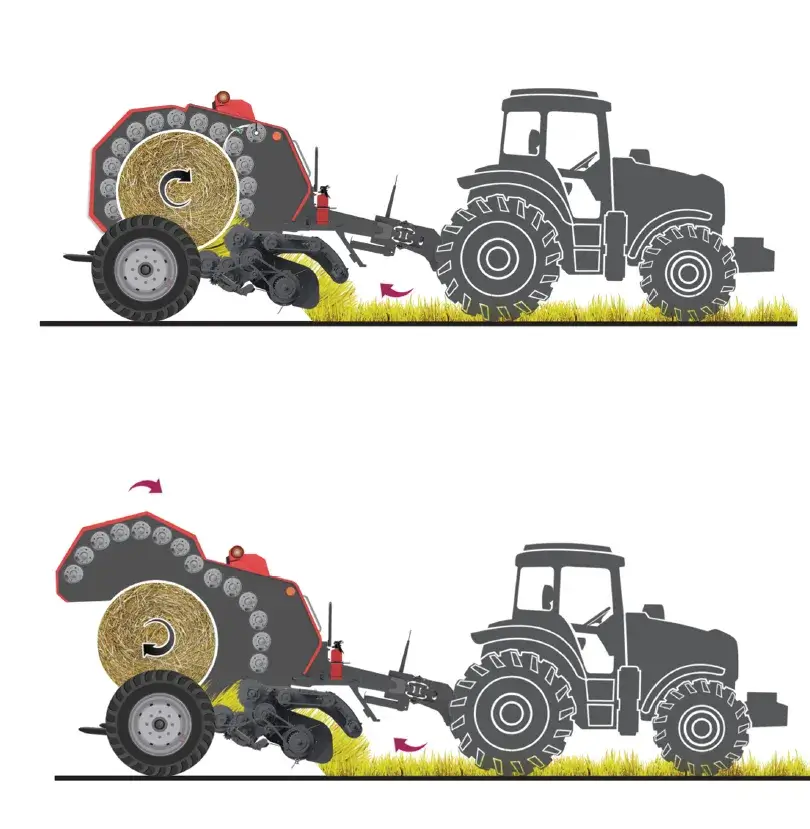

- Quick-connection: The tow-type design allows for flexible rotation of the horizontal tow frame, simplifying the connection process.

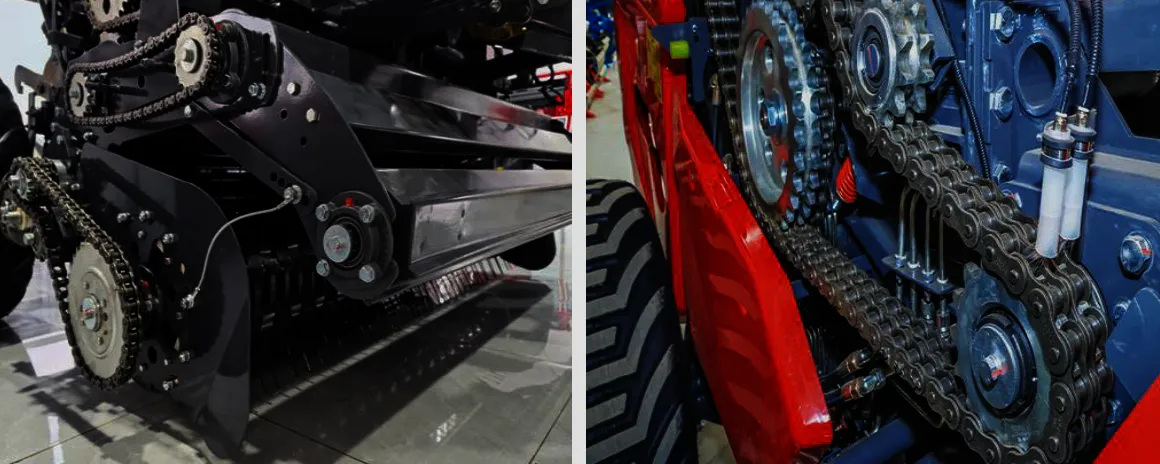

- Rear roller design: Less prone to slippage compared to belt-driven systems.

- High-efficiency operation: Utilizes a double gearbox, enhancing maneuverability in the field; turning requires no power interruption, reducing operational complexity.

- Excellent stability: A rigid, integral connection adapts to uneven terrain, minimizing the risk of mechanical damage.

- Intelligent control: Automatic control via bale density sensors ensures consistent bale quality.

4. Operational Principle: Redefining Baling Efficiency

The 9YG-2.24D Round Baler (S9000 Transcendence Series) represents a paradigm shift in biomass collection technology. Unlike traditional belt balers that struggle with wet or heavy crops, the S9000 Transcendence utilizes a Fixed Chamber Roller System composed of 18 high-strength steel rollers (Φ222mm). This design provides aggressive traction and compression, ensuring reliable bale rotation even with slick, wet silage or tough corn stalks.

The core innovation of the "Transcendence" series lies in its Double-Swivel Gearbox Driveline. Traditional towed balers require the operator to disengage the PTO when making sharp turns to prevent driveshaft damage. The S9000's gearbox is rigidly mounted to a pivoting traction frame, allowing the driveline to articulate up to 100 degrees horizontally and tilt 30 degrees vertically. This mechanical breakthrough enables continuous operation during headland turns, increasing field efficiency by approximately 20% compared to standard models. Employs a "Feed Rotor + Roller" mechanism to force crop into the chamber, minimizing blockages and ensuring a perfectly shaped cylindrical bale every time.

5. Compliance with Global Regulations Like Brazil, Russia

The 9YG series is designed to meet stringent international safety and performance standards, ensuring legal compliance and operational safety across key global markets.

- USA (ASABE): Meets ASABE S318 safety for agricultural equipment and ASABE S279 for lighting and marking. The net wrap system is compatible with standard US mesh sizes.

- European Union (CE): Compliant with the Machinery Directive 2006/42/EC and ISO 4254-1/ISO 4254-7 specific to balers and combine harvesters. Includes required safety guarding for moving parts.

- Brazil (NR-12): Fully adaptable to NR-12 standards, featuring extensive yellow safety guarding, emergency stop protocols, and safety decals in Portuguese.

- Russia (EAC/GOST): Meets GOST R standards for agricultural machinery, ensuring reliability in extreme cold and rough terrain common in the Russian Federation.

6. EP-9YG 2.24D Round Baler S9000 Transcendence directly addresses Brazil market demand.

Application in Global

The global forage market is trending towards High-Density Silage Baling. Farmers are moving away from square bales for silage due to spoilage concerns. Round bales, especially those wrapped with net and film, offer superior anaerobic fermentation conditions.

Application in Brazil | Aplicação das enfardadeiras redondas no Brasil

In Brazil, the trend of biomass recycling (collecting corn stalks and wheat straw for energy production) also requires machines capable of handling tough, coarse stalks. The S9000 Transcendence's reinforced hopper and 20A chain are designed to withstand the high impact loads of corn stalk baling, whereas traditional belt balers often fail due to belt tearing when handling this type of material.

Application in Kazakh | Қазақша дөңгелек пресс-машиналарды қолдану

1. Large-scale Wheat Straw Recovery in the Northern Grain Belt. Every year after harvest, millions of tons of straw are left in the fields.2. Cost-Effective Winter Fodder Reserve. Kazakhstan experiences long, harsh winters, requiring livestock to maintain large reserves of hay.

7. How to Choose the Right Round Baler

When selecting the perfect ラウンドベーラー for your agricultural needs, there are several factors to consider, including the type of crop you're baling, the size of your farm, and your specific operational goals. Whether you're working with round hay bales for livestock feed, preparing hay for storage, or handling other types of crop residues, the right baler can make all the difference.

- Size of the Round Baler

For small-scale farms, a mini round baler can be a great choice, offering the flexibility to handle lighter workloads while being more compact and cost-effective. If you're dealing with larger operations or need to handle round hay bales in high volumes, a larger model like the New Holland 630 round baler or New Holland 640 round baler can provide the higher capacity and efficiency you need. - Weight of the Bale

One important consideration is how much a round bale of hay weighs. If you're working with dense crops like alfalfa, a heavier bale may be the best choice for efficient storage and transportation. Lighter bales, however, may be more appropriate for certain types of hay or if the round bale feeder is used for animals, like horses, to ensure they can easily access the hay. - Feeding and Bale Wrapping

If you're using the hay for round bale feeder for horses, it’s essential to select a baler that can create bales of appropriate size and shape for easy feeding. Additionally, consider investing in round bale hay nets or round bale net wrap. These options help maintain the quality of the hay while providing a convenient and efficient way to store it for future use.

By considering these factors, you can select the ラウンドベーラー that best suits your needs, ensuring efficiency and reliability in your hay handling process.

8. Customer Success Case

"With government support for straw recycling and feed utilization, our demand has been constantly growing. So we purchased this machine; it's easy to operate and maintain. Its performance exceeded our expectations, and what's even better is the national policy of agricultural machinery subsidies—it couldn't be better, hahaha!"

— Inner Mongolia, China

"As a country with leading domestic agricultural machinery technology, we have extremely high requirements for equipment. We tried their round baler with a bit of luck, but to our surprise, it worked exceptionally well. Not only is its performance superior, but the price is also more affordable. Its efficient operation and durability have left us very satisfied with its long-term use, truly impressing me."

— From Germany

“Honestly, this large agricultural baler has brought tremendous efficiency improvements to our ranch. Our beef cattle industry has a huge demand for hay, and this machine helps us harvest and store hay efficiently, greatly improving efficiency. We are extremely satisfied with this round baler!”

— US Beef Farm Manager

"It perfectly meets our needs for a large round baler. We are gradually upgrading our equipment. This round baler is highly efficient and reliable, especially in terms of rapid harvesting and compression. Plus, there are policy incentives, making it excellent value for money."

— Head of Northeast China Farm

10. Factory Customization & OEM Capabilities

We are a fully integrated manufacturer. We don't just assemble; we engineer. We have baling machine design engineers with over 10 years of experience. We will appropriately modify some standard configurations to adapt to local laws and regulations. We will provide different models based on the different transportation specifications in various regions.

PTO Speed: Standard 720rpm can be adjusted to 540rpm or 1000rpm gearboxes to match your tractor fleet.

Hydraulics: Custom couplers (Pioneer, Flat Face)and valve configurations to match other baler brand like John Deere, Case IH, or New Holland systems.

*Disclaimer: This product compatibility reference is for illustrative purposes only and is not an official accessory.

Color & Branding: OEM color matching and private labeling for dealer networks.

11. Maintenance and Care of the 9YG 2.24D Round Baler S9000 Transcendence

To ensure the 9YG 2.24D Round Baler S9000 Transcendence operates smoothly and lasts for years, it’s essential to carry out regular maintenance and proper care. Taking a few simple steps will help keep your baler running efficiently, reduce the need for repairs, and maximize its performance. Here are the key maintenance tips:

1. Regular Inspections

- Check for Wear: Regularly inspect the baler’s key components, such as the pick-up system, rollers, and bearings. Any signs of wear should be addressed promptly to prevent further damage.

- Net Wrap System: Make sure the round bale net and net wrap mechanism are in good condition. Damaged parts can affect bale formation, so check them after every use.

2. Lubrication

- Lubricate Moving Parts: It’s crucial to lubricate all moving components like the chain, gears, and rollers regularly. This minimizes friction, helps prevent wear, and ensures the baler operates smoothly.

- Follow the Maintenance Schedule: Refer to the owner’s manual for the lubrication points and schedule. Pay particular attention to the pick-up chain, cam bearings, and knotters.

3. Cleaning After Use

- Remove Debris: After each use, clean the baler thoroughly to remove any crop residues or dirt. Keeping it clean reduces clogging and prevents rust buildup.

- Pick-Up Teeth: Ensure the pick-up tines are free from debris, allowing for smooth operation during the next use.

4. Hydraulic System Care

- Look for Leaks: Regularly inspect the hydraulic system for leaks. A well-maintained hydraulic system is essential for the baler’s performance, so any issues should be fixed as soon as possible.

- Check Fluid Levels: Keep an eye on the hydraulic oil levels. If the oil level is low, top it up with the recommended fluid to avoid damaging the hydraulic components.

5. Tire Maintenance

- Monitor Tire Pressure: Check the tire pressure regularly and adjust it according to the manufacturer’s recommendations. Proper tire pressure ensures better performance and reduces uneven wear.

- Inspect for Damage: Examine the tires for any damage, such as cuts or punctures. If any issues are found, replace the tires immediately to avoid any disruption to your work.

6. Seasonal Maintenance

- Pre-Season Check: Before each harvest season begins, do a thorough check of the baler. This includes lubricating all moving parts, checking for wear, and testing the baler’s functionality to ensure it’s ready for use.

- Post-Season Storage: After the season ends, clean the baler and store it in a dry, sheltered space. This helps protect it from environmental damage, like rust, and extends its life.

7. Handling Malfunctions

- Troubleshoot: If the baler isn’t working as expected, consult the owner’s manual for troubleshooting tips. Common issues might include inconsistent bale formation, net wrap failure, or feeding problems.

- Professional Help: For more complex issues or if troubleshooting doesn’t resolve the problem, contact a professional technician for repairs. Regular servicing ensures the baler stays in top condition.

By taking care of your 9YG 2.24D Round Baler S9000 Transcendence through these regular maintenance steps, you’ll help it run efficiently and extend its lifespan. Proper care ensures minimal downtime, keeps operational costs low, and ensures your baler is ready to work when you need it most.

12. Relevant Certifications and Qualifications

· ISO 9001: Quality Management System Certification

· ISO 14001: Environmental Management System Certification

· CE Certification: Compliant with European Market Standards

To learn more about our qualifications, please click 私たちについて.

13.Related components.

· PTO Shaft & Tractor Gearbox

· Drive Chain & Sprocket

· Sheave & Pulley

· Pickup Shaft Bearings & Shaft Collar

· Hay Picker Shaft & Hay Picker Stand

· Skids & Abrasion Plates

· Teeth & Hay Picker Springs

Contact us, and we'll send you the Related components PDF of available replacement parts.

FAQ

Q1. How often should I perform maintenance on the 9YG 2.24D Round Baler S9000 Transcendence?

A1. It’s recommended to perform routine maintenance after each use to clear any debris and ensure proper lubrication of moving parts. Additionally, a more comprehensive inspection should be done before and after each season, including checking the hydraulic system, tires, and bale wrapping mechanisms.

Q2. Does this baler use twine or net wrap?

A2. The S9000 Transcendence comes standard with an Automatic Net Wrap System. Net wrap is faster than twine (only 2-3 turns required vs 20+ for twine), reduces bale spoilage, and keeps the bale shape better for transport.

Q3.How does the swivel gearbox work?

A3. The unique double-gearbox design allows the hitch to pivot 100° horizontally relative to the baler body while maintaining a straight PTO shaft alignment. This prevents the "chattering" and U-joint damage common in standard balers during tight turns.

Q4. Is this baler suitable for corn stalks?

A4. Absolutely. The roller chamber design is superior for corn stalks compared to belt balers, as steel rollers don't tear. The "Feed Rotor + Roller" intake system is specifically designed to crush and ingest tough, bulky corn stover efficiently.

Q5. Can the 9YG 2.24D Round Baler S9000 Transcendence handle all types of crops?

A5. Crops that can be baled include wheat, rice, cotton, pasture, corn silage, alfalfa, sugarcane, and reeds.

Q6. How often should I perform maintenance on the 9YG 2.24D Round Baler S9000 Transcendence?

A6. It’s recommended to perform routine maintenance after each use to clear any debris and ensure proper lubrication of moving parts. Additionally, a more comprehensive inspection should be done before and after each season, including checking the hydraulic system, tires, and bale wrapping mechanisms.

Q7. What kind of net wrap does the baler use?

Q7. The 9YG 2.24D Round Baler S9000 Transcendence is compatible with standard round bale hay nets and net wrap, ensuring that each bale is securely wrapped and protected. This helps maintain the quality of the hay and reduces loss during transportation and storage.

Q8. How much horsepower is required to operate the 9YG 2.24D Round Baler S9000 Transcendence?

A8. The 9YG 2.24D Round Baler S9000 Transcendence requires a tractor with a minimum of 55 to 100 kW (approximately 75-135 horsepower) to operate efficiently. The specific horsepower needed depends on the type of crop and the working conditions.

Contact [email protected] for a customized proposal.

編集者: PXY