Descrizione

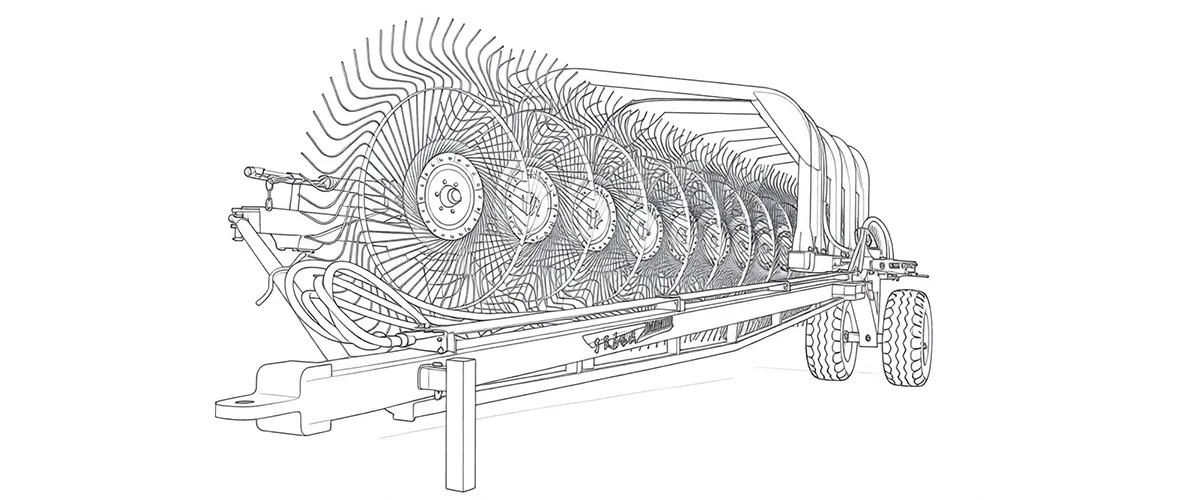

1. Technical Specifications: 9LZY-9.0 Series

| NO. | Articolo | Unità | Specifica |

|---|---|---|---|

| 1 | Nome del modello | / | 9LZY-9.0 Finger Wheel Hay Rake |

| 2 | Structural Type | / | Finger Wheel Type |

| 3 | Tipo di attacco | / | Trainato |

| 4 | Model Specification | / | 9LZY-9.0 |

| 5 | Required Power | kW | 50–55 |

| 6 | Overall Dimensions (L × W × H) | M | 8.4 × 11 × 1.75 (Working Condition) |

| 7 | Machine Weight | kg | 1100 |

| 8 | Working Width | M | 9 |

| 9 | Operating Speed | chilometri all'ora | 8–10 |

| 10 | Transport Speed | chilometri all'ora | 12 |

| 11 | Number of Finger Wheels | pezzi | 15 |

| 12 | Number of Spring Teeth | pezzi | 900 (15 wheels × 60 teeth per wheel) |

| 13 | Operators Required | person | 1 |

| 14 | Windrow Width | M | 0.8–1.2 |

| 15 | Raking Loss Rate | ≤ | 2% |

| 16 | Produttività | hm²/h | 7.2–9 |

2. Key Facts & Performance Metrics

- Massive Coverage: 9.0m operating width utilizing 15 dynamic finger discs.

- High Productivity: Capable of covering 7.2 to 9 hectares per hour, ideal for tight harvest windows.

- Gentle Handling: 900 individual tines (60 per disc) ensure thorough collection without damaging crop roots.

- Hydraulic Control: Complete hydraulic lifting mechanism for seamless transition between work and transport modes.

- Terrain Adaptability: Independent floating discs follow ground contours, making it suitable for uneven terrain in Chungcheong and Jeolla provinces.

3. Redefining Forage Harvest: The 9LZY-9.0 Disc-type Hay Rake

4. Engineering Precision: Working Principles and Material Science

5. Compliance and Safety: Meeting Global & Korean Standards

Navigating the regulatory landscape of agricultural machinery is essential for safe and legal operation. For our partners in South Korea, the 9LZY-9.0 is designed in compliance with the Agricultural Mechanization Promotion Act. Specifically, the hydraulic folding mechanism ensures that the machine’s transport width is reduced to safe levels for public road travel, adhering to the strict width restrictions found on rural Korean roadways. The machine is equipped with mounting points for safety reflectors and slow-moving vehicle (SMV) signage, meeting the requirements of the Korean Ministry of Land, Infrastructure and Transport (MOLIT) for towed agricultural implements.

From a land management perspective, the 9LZY-9.0 supports sustainable farming practices. Its wide flotation tires (400/60-15.5 or similar spec) are designed to minimize ground pressure. In regions like the European Union and South Korea, where soil compaction regulations are becoming stricter to preserve arable land quality, this low-impact design is a significant advantage. Furthermore, the ground-driven nature of the rake eliminates the risk of hydraulic fluid leaks associated with PTO-driven motors on the cutter bar, aligning with environmental protection standards such as ISO 14001. By choosing the 9LZY-9.0, you are ensuring compliance with current safety standards while positioning your operation for future environmental regulations.

6. Customer Success Story:

7. EVER-POWER Factory: personalizzazione e garanzia della qualità

Situato nella zona di sviluppo economico e tecnologico di Hulunbuir, il nostro stabilimento di produzione si estende su 32.000 metri quadrati ed è dotata di macchine per il taglio laser CNC all'avanguardia, linee di saldatura automatiche e linee di verniciatura a polvere elettrostatica. Non siamo solo un'azienda di assemblaggio; siamo un produttore completo con profonde competenze in ricerca e sviluppo.

Servizi di personalizzazione (OEM/ODM): Sappiamo che le condizioni agricole variano da regione a regione. Per il mercato sudcoreano, offriamo opzioni di personalizzazione, tra cui:

• Adattamento idraulico: Regolazione delle pressioni delle valvole per adattarle ai flussi idraulici specifici dei trattori LS o Daedong.

• Aggiornamenti pneumatici: Pneumatici di galleggiamento più larghi opzionali per risaie con fango profondo.

• Colore e marchio: Servizi di branding OEM per rivenditori e distributori.

Noi teniamo Certificazione del sistema di gestione della qualità ISO9001 e sono state riconosciute come impresa nazionale ad alta tecnologia. Ogni pressa 9YG-2.24D viene sottoposta a un rigoroso test di funzionamento continuo di 48 ore prima della spedizione, per garantire l'assenza di difetti all'arrivo.

8. Prodotti correlati

8.1 Cambio:

Modelli compatibili: EP-FK263 (pressa quadrata), serie EP-RC30 (pressa rotonda, rapporto di trasmissione 1:2, compatibile con albero a 6 scanalature da 35 mm).Applicazione: trasmette la potenza della presa di forza al meccanismo di pressatura, adatto per New Holland 630 o John Deere 535. Parametri: coppia > 500 Nm, risparmio di carburante 20%.Perché scegliere questo riduttore: Dimensioni personalizzabili (riducibili a 250-300 mm), resistente ai contaminanti viscosi (fumi di gomma), protezione IP65. Albero cardanico:Modelli compatibili: serie EP-PTO (scanalatura Z6 da 1-3/8″, lunghezza regolabile 600-1200 mm).Applicazione: collega il trattore alla trasmissione principale della pressa, adatto per il tipo 9YG-1.0C. Efficienza di trasmissione della coppia >95%, compatibile con flange SAE/EURO.Perché è adatto: design impermeabile, adatto per operazioni di insilato umido; sostituibile con la serie Weasler.

8.2 Catene e pignoni:

Modelli compatibili: ANSI catene, con pignone EP (passo 12,7-19,05 mm, diametro rullo 10-12 mm).Applicazione: Utilizzato in nastri trasportatori o meccanismi di legatura, adatto per il trasporto di paglia in presse quadrate/rotonde. Larghezza 25-40 mm, materiale in acciaio resistente all'usura.Perché è adatto: compatibile con le attrezzature Kobelco o HF Group, riduce il rischio di rottura della catena; disponibile un'opzione per uso alimentare per l'insilato.

8.3 Giunti:

Modelli compatibili: Giunto EP serie 200 (coppia di accoppiamento 500-1000 Nm).Applicazione: collega il cambio al rullo di pressatura, smorza le vibrazioni.Perché è adatto: elevata durata nel tempo, compatibile con Bondioli e Pavesi.

8.4 Cilindro idraulico:

Cilindro idraulico: Serie EP-HC (alesaggio 50-100 mm, corsa 300-600 mm), adatta al sollevamento di balle.Cuscinetti e guarnizioni: cuscinetti 6208-2RS, durata L10 >10000 ore, guarnizione antipolvere.Tabella di compatibilità: completamente intercambiabile con Comer 250T (coppia corrispondente, solo 35% del prezzo); la flangia corrisponde al modello PTO a 4 bulloni nordamericano.* Disclaimer: gli altri marchi sopra menzionati sono forniti esclusivamente a scopo illustrativo. Non offriamo prodotti o apparecchiature originali con questi marchi.* I parametri variano a seconda delle condizioni di lavoro; fare riferimento ai disegni effettivi. Si consiglia di verificare le dimensioni dell'interfaccia prima della selezione.

9. Frequently Asked Questions (FAQ)

Q1. What is the current price for the 9LZY-9.0 hay rake for a tractor delivered to Busan port?

A1. Pricing varies based on steel costs and shipping logistics. For a precise CIF Busan quote, please get in touch with our sales team directly via the “Get a Quote” button.

Q2. How wide is a 10-wheel hay rake compared to this 15-wheel 9LZY-9.0 model?

A2. A standard 10-wheel rake typically covers about 6-7 meters. The 9LZY-9.0, with 15 wheels, offers a significantly larger 9-meter width, increasing productivity by over 30%.

Q3. What is a high-capacity hay rake, and does the 9LZY-9.0 fit this category?

A3. Yes, “high capacity” refers to rakes that can cover large acreages quickly. With a 9m width and 9 hm²/h productivity, the 9LZY-9.0 is definitely classified as high capacity.

Q4. Can I use this rake as a pull-behind rake for sticks or land clearing?

A4. No, this machine is precision-engineered for forage. Using it as a pull behind rake for sticks will damage the specialized spring steel tines and void the warranty.

Q5. How long to wait before raking hay with the 9LZY-9.0 for best results?

A5. It depends on the crop, but generally, wait until the top of the swath is dry (usually 1 day after cutting). The 9LZY-9.0 can also be used to turn damp hay to accelerate drying.

Q6. Are replacement tines for this rotary hay rake style available in South Korea?

A6. Yes, we provide a spare parts kit with purchase. Furthermore, the 65Mn tines use standard international mounting, making them compatible with many local aftermarket suppliers.

Q7. Does the 9LZY-9.0 require a PTO connection to operate the spinning wheels?

A7. No, this is a ground-driven finger wheel rake. The forward motion of the tractor spins the wheels, saving fuel and simplifying maintenance compared to PTO rakes.

Q8. How does this compare to a parallel bar hay rake for alfalfa harvesting?

A8. Parallel bar rakes are gentler but slower and narrower. The 9LZY-9.0 is much faster and wider (“high capacity”), though slightly more aggressive, making it ideal for large-scale operations.

Q9. What is the Minimum Order Quantity (MOQ) for an OEM order of these rakes?

A9. We can ship single units, but for optimal shipping costs in a 40ft container, we recommend ordering 3-5 units. OEM customization usually requires a minimum of 5 units.

Q10. Can this rake handle heavy, wet rice straw common in Korean harvests?

A10. Absolutely. The Q345B frame and heavy-duty 65Mn tines are specifically tested to handle the weight and density of wet rice straw without clogging or bending.

Redattore: PXY