Description

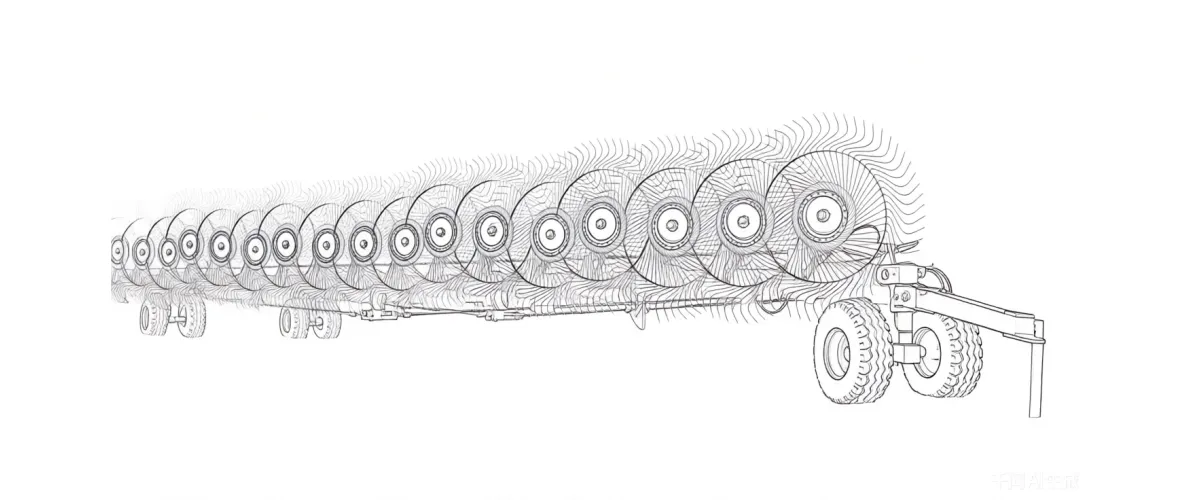

1. Technical Specifications: 9LZD-9.0 Series

| Non. | Article | Unité | Spécification |

|---|---|---|---|

| 1 | Nom du modèle | / | 9LZD-9.0 Finger Wheel Hay Rake |

| 2 | Structural Type | / | Finger Wheel Type |

| 3 | Type d'attelage | / | Traîné |

| 4 | Model Specification | / | 9LZD-9.0 |

| 5 | Required Power | kW | 55–75 |

| 6 | Overall Dimensions (L × W × H) | m | 16.8 × 3.9 × 1.6 (Working Condition) |

| 7 | Poids de la machine | kg | 1240 |

| 8 | Working Width | m | 9 |

| 9 | Vitesse de fonctionnement | km/h | 8–10 |

| 10 | Transport Speed | km/h | 12 |

| 11 | Number of Finger Wheels | pièces | 17 |

| 12 | Number of Spring Teeth | pièces | 1020 (17 wheels × 60 teeth per wheel) |

| 13 | Operators Required | person | 1 |

| 14 | Windrow Width | m | 0.8–1.2 |

| 15 | Raking Loss Rate | ≤ | 2% |

| 16 | Productivité | hm²/h | 7.2–9 |

2. Key Facts & Performance Metrics

- Ultra-Wide Coverage: 9.0m operating width driven by 17 dynamic finger discs (1020 total tines).

- Productivité élevée : Achieves work rates of 7.2 to 9 hm²/h, significantly outperforming standard rotary rakes.

- Ground-Driven Efficiency: Requires no PTO input; the finger wheels are driven by ground contact, saving tractor fuel.

- Hydraulic Precision: Full hydraulic lifting and folding system ensures seamless transition between transport and working modes.

- Terrain Adaptability: Floating finger wheel design follows ground contours, ideal for the rolling hills of Jeolla and Gyeongsang provinces.

3. The Ultimate Forage Solution: 9LZD-9.0 Disc-type Hay Rake

4. Engineering Mechanics: Working Principles and Material Science

5. Regulatory Compliance: Safety and Land Management Standards

6. Market Analysis: The Demand for High-Capacity Solutions

The agricultural machinery landscape in South Korea and globally is shifting decisively towards efficiency and scale. With the rural workforce aging and labor costs rising, farmers are moving away from smaller, labor-intensive implements. The disc-type hay rake search trends indicate a preference for units like the 9LZD-9.0 that can replace the work of two or three smaller rakes. While 8-10 wheel rakes were once standard, the 17-wheel configuration is becoming the new benchmark for professional contractors and large cooperatives.

This trend is driven by the need to match the speed of modern high-density balers and forage harvesters. Additionally, there is a growing awareness of “feed hygiene.” Farmers are increasingly rejecting “parallel bar hay rake” models that can drag soil into the windrow, favoring the cleaner lift of finger wheel rakes. The marketis expanding, with a projected 15% annual growth in the 9-meter+ segment over the next five years in the Asian Pacific region.

7. Tractor & Implement Compatibility

| Composant | Compatibility Details |

|---|---|

| Tractor Brand (Korea) | LS Mtron (XP/MT Series), TYM (T1003/T1103), Daedong (Kioti HX Series) with 75-102 HP. |

| Hydraulic System | Requires 1 Rear Remote Valve (Double Acting) for lift/fold control. Standard ISO hydraulic couplers. |

| Type d'attelage | Standard Agricultural Drawbar / Clevis Hitch. Adaptable to Category II/III dimensions. |

| Terrain Suitability | Flat pasture, rice paddies (post-harvest), gentle slopes. Not recommended for forestry or deep mud. |

*Avertissement : Les autres marques citées ci-dessus sont fournies à titre indicatif uniquement. Nous ne commercialisons aucun produit ni équipement original portant ces marques.

8. Customer Success Story:

9. EVER-POWER Raker Manufacturer: Customization & Quality Assurance

Située dans la zone de développement économique et technologique de Hulunbuir, notre usine de fabrication s'étend sur plus de 32 000 mètres carrés Notre usine est équipée de machines de découpe laser CNC de pointe, de lignes de soudage automatisées et de lignes de revêtement en poudre électrostatique. Nous ne sommes pas un simple assembleur ; nous sommes un fabricant complet doté d’importantes capacités de recherche et développement.

Services de personnalisation (OEM/ODM) : Nous savons que les conditions agricoles varient selon les régions. Pour le marché sud-coréen, nous proposons des options de personnalisation, notamment :

• Adaptation hydraulique : Réglage des pressions des soupapes pour correspondre aux débits hydrauliques spécifiques des tracteurs LS ou Daedong.

• Améliorations des pneus : Pneus de flottaison plus larges en option pour les rizières à boue profonde.

• Couleur et image de marque : Services de branding OEM pour les concessionnaires et les distributeurs.

Nous tenons Certification du système de gestion de la qualité ISO9001 et ont été reconnues comme entreprise nationale de haute technologie. Chaque presse à balles 9YG-2.24D subit un test rigoureux de fonctionnement continu de 48 heures avant expédition afin de garantir l'absence de défauts à la livraison.

10. Related products

10.1 Gearbox:

Modèles compatibles : EP-FK263 (presse à balles carrées), série EP-RC30 (presse à balles rondes, rapport de transmission 1:2, compatible avec arbre cannelé 6 cannelures de 35 mm).Application : Transmet la puissance de la prise de force au mécanisme de pressage, convient aux New Holland 630 ou John Deere 535. Paramètres : Couple > 500 Nm, économie de carburant 20%.Pourquoi choisir cette boîte de vitesses : dimensions personnalisables (réductibles à 250-300 mm), résistance aux contaminants visqueux (émanations de caoutchouc), protection IP65. Arbre de prise de force :Modèles compatibles : série EP-PTO (cannelure Z6 1-3/8″, longueur réglable 600-1200 mm).Application : Raccordement du tracteur à la transmission principale de la presse à balles, compatible avec le modèle 9YG-1.0C. Rendement de transmission du couple > 95%, compatible avec les brides SAE/EURO.Pourquoi il convient : Conception étanche, adapté aux opérations d’ensilage humide ; remplaçable par la série Weasler.

10.2 Chaînes et pignons :

Modèles compatibles : ANSI chaînes, avec pignon EP (pas 12,7-19,05 mm, diamètre du rouleau 10-12 mm).Application : Utilisé dans les convoyeurs à bande ou les mécanismes de liage, convient au transport de paille en balles carrées/rondes. Largeur : 25 à 40 mm, matériau : acier résistant à l’usure.Pourquoi il convient : Compatible avec les équipements Kobelco ou HF Group, réduit le risque de rupture de chaîne ; une option de qualité alimentaire est disponible pour l’ensilage.

10.3 Couplings:

Modèles compatibles : Accouplement EP série 200 (couple adapté 500-1000 Nm).Application : Relie la boîte de vitesses au rouleau de la presse à balles, amortit les vibrations.Pourquoi il convient : Durabilité à grande échelle, compatible avec Bondioli et Pavesi.

10.4 Cylindre hydraulique:

Vérin hydraulique : Série EP-HC (alésage 50-100 mm, course 300-600 mm), adaptée au levage de balles.Roulements et joints : roulements 6208-2RS, durée de vie L10 > 10 000 heures, joint étanche à la poussière.Tableau de compatibilité : Entièrement interchangeable avec Comer 250T (couple correspondant, seulement 35% de moins au prix) ; la bride correspond au modèle de prise de force à 4 boulons nord-américain.* Avertissement : Les autres marques citées ci-dessus sont fournies à titre indicatif uniquement. Nous ne proposons aucun produit ni équipement original portant ces marques.Les paramètres varient selon les conditions de fonctionnement ; veuillez vous référer aux schémas. Il est recommandé de vérifier les dimensions de l’interface avant de procéder à la sélection.

11. Frequently Asked Questions (FAQ)

Q1. What is the estimated price for the 9LZD-9.0 disc-type hay rake for sale delivered to Incheon?

A1. Pricing depends on raw material costs and current shipping rates. For a precise CIF Incheon quote including customs documentation, please use the “Get a Quote” button to contact our sales team.

Q2. How wide is this 17-wheel hay rake compared to a standard 10-wheel hay rake?

A2. A standard 10-wheel rake covers about 6-7 meters. The 9LZD-9.0 with 17 wheels offers a massive 9-meter working width, increasing coverage by nearly 40% per pass.

Q3. Where can I find disc-type hay rake parts, like replacement tines in South Korea?

A3. We provide a spare parts kit with every machine purchase. Additionally, our 65Mn tines use standard international mounting specs, making them compatible with many local aftermarket suppliers or direct orders from us.

Q4. Is the 9LZD-9.0 considered a high-capacity hay rake suitable for contractors?

A4. Absolutely. With a 9m width and productivity of up to 9 hectares per hour, it is specifically designed for high-capacity commercial operations and agricultural contractors.

Q5. Can this rake be used as a used hay rake for sale near me, or do you only sell new?

A5. EVER-POWER manufactures and sells only brand-new equipment. However, our durable build quality means these units hold their value well if you ever decide to sell it as a used unit later.

Q6. How does this compare to a parallel bar hay rake for handling alfalfa?

A6. While parallel bar rakes are gentle, they are much slower and narrower. The 9LZD-9.0 offers a good balance of gentle handling via ground-drive wheels while providing significantly higher speed and capacity.

Q7. What hydraulic connections does my tractor need for this disc-type hay rake?

A7. You will need one set of rear remote hydraulic valves (two ports, double-acting) to operate the hydraulic cylinder that lifts and folds the rake arms for transport.

Q8. Can I see disc-type hay rake reviews from other customers before purchasing?

A8. Yes, we can provide testimonials and case studies from our international clients. Please contact our sales team, and we will share relevant feedback from users in similar agricultural climates.

Q9. How long to wait before raking hay using the 9LZD-9.0 model?

A10. It depends on moisture, but typically you rake when moisture is around 40-50% to prevent leaf shatter. The 9LZD-9.0 can also be used for turning damp hay (tedding) to accelerate this drying process.

Éditeur : PXY