Description

1. 9GQY-3.2 Technical Engineering Specifications

| Technical Feature | 9GQY-3.2 Parameters |

|---|---|

| Working Width | 3200 mm (3.2 Meters) |

| Machine Type | Trailed / Towed Disc Type |

| Tractor Power Requirement | 80 – 120 HP (cv) |

| Conditioning Method | Adjustable Intensity Rollers |

| PTO Input Speed | 540 / 1000 RPM (Selectable) |

| Cutting Disc Speed | Up to 3000 RPM |

| Weight | Approx. 1850 Kg |

2. Five Key Facts About the 9GQY-3.2 Mower Conditioner

- Superior Cutting Width: A full 3.2m working width enables high hectares-per-hour productivity, reducing labor costs for commercial forage producers.

- Integrated Conditioning System: Heavy-duty rubber or steel rollers crush stems to release moisture, accelerating the hay curing process by up to 50%.

- Trailed Stability: The towed configuration provides superior stability on sloped terrains compared to side-mounted units, essential for the mountainous fields of Gangwon-do.

- Hydraulic Control Precision: Equipped with advanced hydraulic folding and height adjustment, allowing operators to adapt to variable soil conditions instantly.

- Manganese Steel Durability: High-resistance cutter bars and discs treated to HRc 52+ hardness ensure long life in abrasive volcanic or stony soils.

3. High-Output Forage Harvesting: The Engineering Edge of 9GQY-3.2

In the rapidly evolving agricultural landscape of South Korea, forage quality is the cornerstone of premium Hanwoo beef and dairy production. The 9GQY-3.2 Mower Conditioner addresses the critical bottleneck of drying time in high-humidity regions. As a specialized mower conditioner manufacturer, Jiujia has engineered the 9GQY series with a high-torque mechanical transmission that maximizes energy transfer from the tractor’s PTO. The 3.2-meter disc cutter bar utilizes a modular design, allowing for rapid blade replacement in the field. Unlike standard mowers, the conditioning rollers on the 9GQY-3.2 are adjustable, allowing operators to vary the conditioning intensity based on crop density and moisture levels. This is particularly vital for the Gyeonggi and Jeju provinces, where soil types vary from heavy clay to volcanic ash. By providing a uniform windrow, the 9GQY-3.2 sets the stage for efficient baling with a forage harvester or square baler, ensuring that the moisture profile remains consistent throughout the stack. Professional growers prioritize this equipment because it minimizes leaf loss in high-value alfalfa while ensuring the tough stems are sufficiently cracked to prevent mold during storage.

4. Regulatory Compliance

Operating high-capacity agricultural machinery in South Korea mandates strict adherence to the Agricultural Machinery Safety Management Act. The 9GQY-3.2 is built to exceed these safety benchmarks, featuring complete PTO shielding and hydraulic safety locks for road transport. Furthermore, South Korean land management construction laws emphasize the prevention of soil compaction and topsoil degradation. The 9GQY-3.2 trailed disc mower conditioner is equipped with high-flotation tires that distribute weight evenly, ensuring that the soil structure in permanent pastures is preserved for future growth cycles.

Globally, this equipment aligns with ISO 4254-1 standards for agricultural machinery safety and environmental stewardship.

In Europe and Australia, regulations regarding noise pollution and the disposal of high-wear manganese steel components are stringent; Jiujia’s manufacturing process integrates recyclable alloy steel and low-noise gear drives to meet these international ESG (Environmental, Social, and Governance) targets. Whether you are a commercial contractor in the USA or a cattle cooperative in Pyeongchang, the 9GQY-3.2 provides the legal and technical assurance required for modern, compliant farming operations.

5. Tractor Compatibility & Replacement Standards

The 9GQY-3.2 is engineered to serve as a high-durability replacement for or complement to global agricultural brands prevalent in South Korea.

| Compatible Tractor Brand | Linkage / PTO Match | Compatibility Status |

|---|---|---|

| LS Mtron (Korea) | Category 2 Standard / 540 RPM | Intégration parfaite |

| TYM / Daedong (Korea) | Category 2/3 / 1000 RPM | Seamless Support |

| John Deere / Kubota | ISO Standard 3-Point / PTO | Universal Fit |

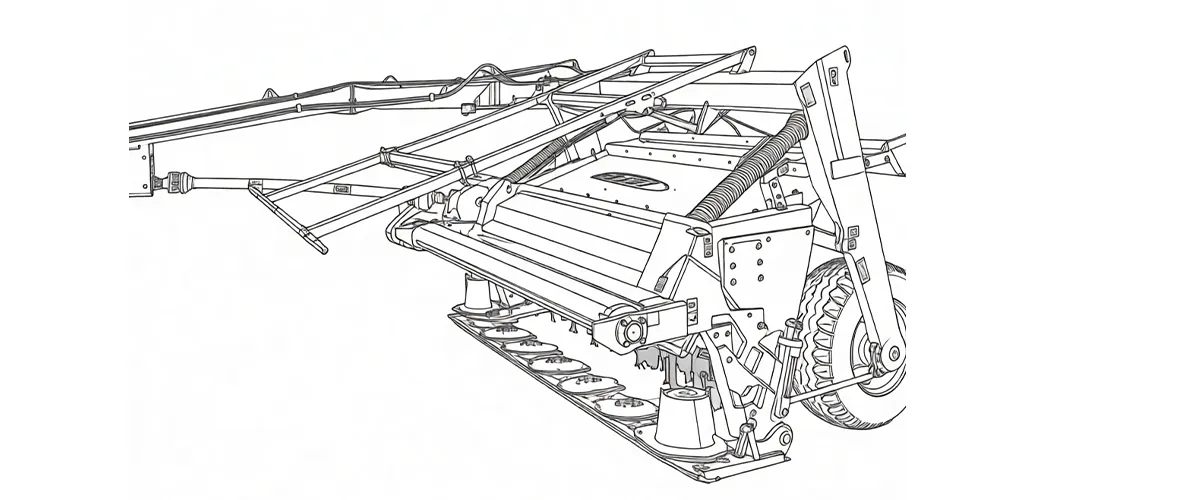

6. Working Principle: Centrifugal Cutting and Mechanical Conditioning

7. Market Trend Analysis: The Future of Forage Harvest in East Asia

The global trend in forage harvesting is moving rapidly toward “One-Pass Efficiency” and “Precision Drying.” In South Korea, the rising cost of imported feed is forcing farmers to produce more high-quality hay locally. We are seeing a significant shift from simple disc mowers to integrated mower conditioners for sale, like the 9GQY-3.2. This is driven by the need to maximize weather windows in unpredictable monsoon climates; reducing field drying time by even 24 hours can be the difference between premium hay and livestock-grade silage. Furthermore, as agricultural robots and GPS-guided tractors become standard, there is an increasing demand for trailed implements that offer predictable tracking and high-speed operation. Jiujia is at the forefront of this trend, integrating sensors for real-time height control and wear monitoring. The demand for mower conditioner manufacturers who can provide local support and parts in South Korea is projected to grow by 12% annually as the Hanwoo industry continues to professionalize its supply chain.

8. Customer Success Case:

Client 1 Profile: South Korea, Gyeonggi-do – Hanwoo Beef Producer

Customer Reviews:

Client 2 Profile: Australia, Murray-Darling Basin – Large Cattle Farm

Customer Reviews:

Client 3 Profile: United States, California – Dairy Farm

Customer Reviews:

Client 4 Profile: New Zealand, Waikato – Sheep and Beef Farm

Customer Reviews:

Client 5 Profile: Brazil, Mato Grosso – Livestock Feed Production

Customer Reviews:

9. EVER-POWER Factory: Customization & Quality Assurance

Située dans la zone de développement économique et technologique de Hulunbuir, notre usine de fabrication s'étend sur plus de 32 000 mètres carrés Notre usine est équipée de machines de découpe laser CNC de pointe, de lignes de soudage automatisées et de lignes de revêtement en poudre électrostatique. Nous ne sommes pas un simple assembleur ; nous sommes un fabricant complet doté d’importantes capacités de recherche et développement.

Services de personnalisation (OEM/ODM) : Nous savons que les conditions agricoles varient selon les régions. Pour le marché sud-coréen, nous proposons des options de personnalisation, notamment :

• Adaptation hydraulique : Réglage des pressions des soupapes pour correspondre aux débits hydrauliques spécifiques des tracteurs LS ou Daedong.

• Améliorations des pneus : Pneus de flottaison plus larges en option pour les rizières à boue profonde.

• Couleur et image de marque : Services de branding OEM pour les concessionnaires et les distributeurs.

Nous tenons Certification du système de gestion de la qualité ISO9001 et ont été reconnues comme entreprise nationale de haute technologie. Chaque presse à balles 9YG-2.24D subit un test rigoureux de fonctionnement continu de 48 heures avant expédition afin de garantir l'absence de défauts à la livraison.

10. Related products

10.1 Gearbox:

Modèles compatibles : EP-FK263 (presse à balles carrées), série EP-RC30 (presse à balles rondes, rapport de transmission 1:2, compatible avec arbre cannelé 6 cannelures de 35 mm).Application : Transmet la puissance de la prise de force au mécanisme de pressage, convient aux New Holland 630 ou John Deere 535. Paramètres : Couple > 500 Nm, économie de carburant 20%.Pourquoi choisir cette boîte de vitesses : dimensions personnalisables (réductibles à 250-300 mm), résistance aux contaminants visqueux (émanations de caoutchouc), protection IP65. Arbre de prise de force :Modèles compatibles : série EP-PTO (cannelure Z6 1-3/8″, longueur réglable 600-1200 mm).Application : Raccordement du tracteur à la transmission principale de la presse à balles, compatible avec le modèle 9YG-1.0C. Rendement de transmission du couple > 95%, compatible avec les brides SAE/EURO.Pourquoi il convient : Conception étanche, adapté aux opérations d’ensilage humide ; remplaçable par la série Weasler.

10.2 Chaînes et pignons :

Modèles compatibles : ANSI chaînes, avec pignon EP (pas 12,7-19,05 mm, diamètre du rouleau 10-12 mm).Application : Utilisé dans les convoyeurs à bande ou les mécanismes de liage, convient au transport de paille en balles carrées/rondes. Largeur : 25 à 40 mm, matériau : acier résistant à l’usure.Pourquoi il convient : Compatible avec les équipements Kobelco ou HF Group, réduit le risque de rupture de chaîne ; une option de qualité alimentaire est disponible pour l’ensilage.

10.3 Couplings:

Modèles compatibles : Accouplement EP série 200 (couple adapté 500-1000 Nm).Application : Relie la boîte de vitesses au rouleau de la presse à balles, amortit les vibrations.Pourquoi il convient : Durabilité à grande échelle, compatible avec Bondioli et Pavesi.

10.4 Cylindre hydraulique:

Vérin hydraulique : Série EP-HC (alésage 50-100 mm, course 300-600 mm), adaptée au levage de balles.Roulements et joints : roulements 6208-2RS, durée de vie L10 > 10 000 heures, joint étanche à la poussière.Tableau de compatibilité : Entièrement interchangeable avec Comer 250T (couple correspondant, seulement 35% de moins au prix) ; la bride correspond au modèle de prise de force à 4 boulons nord-américain.* Avertissement : Les autres marques citées ci-dessus sont fournies à titre indicatif uniquement. Nous ne proposons aucun produit ni équipement original portant ces marques.Les paramètres varient selon les conditions de fonctionnement ; veuillez vous référer aux schémas. Il est recommandé de vérifier les dimensions de l’interface avant de procéder à la sélection.

11. Agricultural Professional FAQ

Q1. How much does a professional 9GQY-3.2 trailed disc mower conditioner cost for delivery to South Korea?

A1. The total investment for a 9GQY-3.2 **mower conditioner for sale** depends on your specific customization needs, such as roller material and shipping logistics to Busan or Incheon. To receive a precise **quote** including regional duties and South Korean compliance support, please click our ‘Get a Quote’ button or contact our regional sales office for current **prices**.

Q2. Where can I find a reliable mower conditioner manufacturer that offers local maintenance support in Gyeonggi-do?

A2. Jiujia provides dedicated technical support across South Korea through our network of industrial partners. We offer 24-hour spare parts shipping for the 9GQY-3.2 series, ensuring that your harvest isn’t delayed during the critical cutting window in Gyeonggi-do or Gangwon-do.

Q3. What is the recommended tractor horsepower for operating the 9GQY-3.2 mower conditioner on sloped Korean terrain?

A3. For the best performance on sloped fields typical of rural South Korea, we recommend a tractor with at least 100 HP. This ensures the hydraulic system has sufficient pressure to manage the folding mechanisms while maintaining a consistent 540/1000 RPM PTO speed for high-yield cutting.

Q4. Which conditioning roller material should I choose for high-moisture alfalfa crops in Jeju Island?

A4. For high-moisture alfalfa or leafy forage in Jeju, our high-density rubber conditioning rollers are ideal. They provide a gentle yet effective crimp that breaks the stem without damaging the nutrient-rich leaves, which is essential for premium forage production under the **Farmland Act** quality guidelines.

Q5. How does a trailed mower conditioner compare to a side-mounted disc mower regarding soil compaction?

A5. A **trailed disc mower conditioner** like the 9GQY-3.2 distributes its 1850 Kg weight across its own high-flotation tires. This significantly reduces the vertical load on the tractor’s rear axle compared to mounted units, minimizing soil compaction and promoting healthier regrowth in accordance with South Korean soil stewardship regulations.

Q6. When is the best time to replace the blades on the 9GQY-3.2 to ensure the best hay quality?

A6. To maintain **best potato digger** (comparative industry standard) levels of cutting precision, we recommend inspecting the blades every 50 operational hours. If you notice “ragged” cuts or increased fuel consumption, it’s time to flip or replace the reversible blades. Our modular disc design makes this a 10-minute task.

Q7. Why should I invest in a mower conditioner instead of a standard disc mower for my livestock operation?

A7. A mower conditioner accelerates the drying process by crushing the crop stems. In South Korea’s humid climate, this reduces the risk of mold and allows you to bale hay sooner. Standard disc mowers require the crop to dry naturally, which often takes twice as long and risks exposure to rain.

Q8. What are the legal requirements for agricultural machinery road transport for 3.2-meter implements in Korea?

A8. Implements with a width exceeding 3 meters, like the 9GQY-3.2, require hydraulic folding for road transport. Our unit folds within standard lane widths and includes reflective safety markers and light kits that comply with the **Korean Ministry of Land, Infrastructure and Transport** safety codes.

Q9. How do I adjust the conditioning intensity on the 9GQY-3.2 for different types of forage grass?

A9. Adjustment is simple via a manual or hydraulic tensioning system on the conditioning rollers. For thin-stemmed grasses, you can reduce the pressure; for thick-stemmed alfalfa or sorghum, increasing the pressure ensures the stems are sufficiently cracked for rapid curing.

Q10. Is the Jiujia 9GQY-3.2 compatible with high-capacity forage harvesters from other brands?

A10. Yes, the 9GQY-3.2 is designed to create a uniform, center-discharge windrow that is perfectly matched for pick-up by high-capacity balers or **forage harvester** units from brands like LS Mtron, John Deere, or Claas, ensuring a seamless harvest workflow.

Éditeur : PXY

*Avertissement : Les autres marques citées ci-dessus sont fournies à titre indicatif uniquement. Nous ne commercialisons aucun produit ni équipement original portant ces marques.