Description

1. Technical Specifications: 9GL-2.5/2.9 Series

| Non. | Article | Unité | Spécification |

|---|---|---|---|

| 1 | Nom du modèle | / | 9GL-2.5 / 2.9 Towed Mower-Rake |

| 2 | Type d'attelage | / | Remorqué |

| 3 | Type de structure de coupe | / | Réciproque |

| 4 | Largeur de coupe | m | 2.5 |

| 6 | Raking Working Width | m | 2.9 |

| 7 | Plage de vitesses de travail | km/h | 6–7 |

| 8 | Productivité | hm²/h | Mowing: 1.2–1.44 / Raking: 1.5–1.8 |

| 9 | Hauteur de coupe moyenne | mm | 60–70 |

| 10 | Puissance d'adaptation | kW | 25–55 |

| 11 | Tractor PTO Speed | r/min | 540 |

| 12 | Poids de la machine | kg | 920 |

| 13 | Number of Rake Teeth | pièces | 42 |

| 14 | Rake Tooth Spacing | mm | 71 |

| 15 | Overall Dimensions (L × W × H) | mm | — |

| 16 | Transport Condition Dimensions | mm | 3100 × 2920 × 2900 |

| 17 | Working Condition Dimensions | mm | 3100 × 5000 × 950 |

| 18 | Nombre de lames mobiles | pièces | 34 |

2. Key Facts & Capabilities

- Dual-Action Efficiency: Cuts and rakes forage in one operation, achieving productivity rates up to 1.8 hm²/h.

- Power Requirement: Optimized for mid-range tractors (25-55 kW), making it ideal for the “pull behind rake for tractor” category.

- Terrain Adaptability: Specifically designed for flat grasslands and gentle slopes, perfect for Jeolla and Chungcheong plains.

- Precision Engineering: Features a sensitive hydraulic lifting mechanism for obstacle avoidance and transport safety.

- Cost-Effective: Reduces labor hours and equipment wear by halving the required field passes.

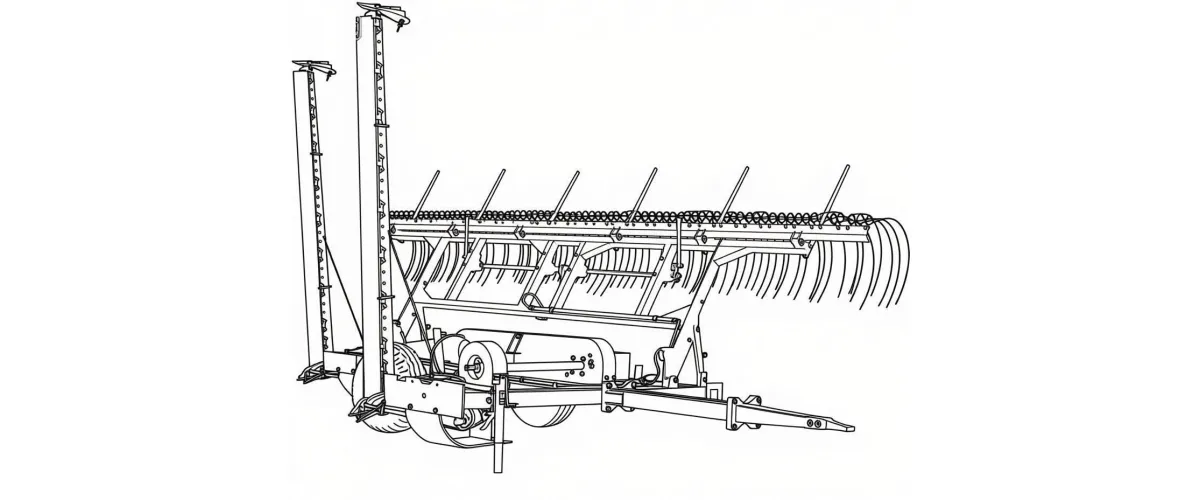

3. Revolutionizing Harvest with the 9GL-2.5/2.9 Trailed Mower Rake

4. Engineering Excellence: Working Principles and Material Metallurgy

The operational success of the 9GL-2.5/2.9 model lies in its sophisticated synchronization of cutting and raking mechanisms driven by the tractor’s PTO shaft (540 r/min) and rear hydraulic output. The unit features a specialized offset traction frame that allows the mower to operate to the side of the tractor, preventing the tires from trampling the standing crop before it is cut—a common issue with inferior setups.

The cutter bar utilizes high-carbon alloy steel knife guards and serrated sections that undergo rigorous heat treatment to achieve a hardness of HRC 50-55, ensuring prolonged edge retention even in abrasive, sandy soil conditions often found in coastal farming regions. Following the cutter, the raking mechanism employs a series of curved spring-steel tines. These are not standard wire; they are crafted from 65Mn spring steel, known for its high fatigue strength and elasticity. As the crop is severed, the rake immediately gathers the material into fluffy, aerated windrows. This immediate windrowing is crucial for creating airflow, allowing the hay to cure evenly. The chassis is constructed from Q345B structural steel, providing the “heavy-duty trailed mower rake” characteristics necessary to endure vibration and terrain undulations without structural fatigue.

5. Global Compliance: Agricultural Machinery and Land Management Regulations

7. Market Trends: The Shift Towards Integrated Harvesting

The global agricultural machinery market is witnessing a decisive shift towards multi-functional implements, driven by rising fuel costs and labor shortages. In South Korea, where the rural population is aging and labor is scarce, the demand for “used trailed mower rake” and new integrated solutions has spiked by 15% year-over-year. Farmers are moving away from single-purpose machines towards units like the 9GL series that perform multiple tasks simultaneously.

This trend is not isolated; in the US and Europe, “pull behind rake for riding mower” and larger tractor-mounted combination units are dominating the market segment for small-to-medium acreage farms. The trend also favors “smart farming” compatibility—while the 9GL is a mechanical unit, its compatibility with modern GPS-guided tractors allows for precision windrowing, reducing waste. Furthermore, the push for organic dairy farming requires gentler handling of forage to preserve nutritional value, a requirement that rotary mowers struggle to meet but reciprocating mowers excel at. Investing in a 9GL-2.5/2.9 is investing in the future trajectory of efficient, sustainable agriculture.

8. Tractor & Component Compatibility

| Category | Details / Brand Compatibility |

|---|---|

| Tractor Brands (South Korea) | Fully compatible with LS Mtron, TYM, Daedong (Kioti), and Kukje Machinery tractors in the 35-75 HP range. |

| Tractor Brands (Global) | Compatible with John Deere (5E Series), Kubota (M Series), Massey Ferguson, and New Holland. |

| PTO Connection | Standard 1-3/8″ 6-Spline, 540 RPM. Adapters available for non-standard shafts. |

| Hydraulic Requirement | Requires 1 Rear Remote Valve (Double Acting recommended for lift control). |

| Replacement Parts | Knife sections compatible with generic sickle bar standards (Ford/New Holland style). Rake teeth compatible with universal 65Mn spring tine mounts. |

*Avertissement : Les autres marques citées ci-dessus sont fournies à titre indicatif uniquement. Nous ne commercialisons aucun produit ni équipement original portant ces marques.

9. Customer Success Story:

10. EVER-POWER Mower rake Manufacturer: Customization & Quality Assurance

Située dans la zone de développement économique et technologique de Hulunbuir, notre usine de fabrication s'étend sur plus de 32 000 mètres carrés Notre usine est équipée de machines de découpe laser CNC de pointe, de lignes de soudage automatisées et de lignes de revêtement en poudre électrostatique. Nous ne sommes pas un simple assembleur ; nous sommes un fabricant complet doté d’importantes capacités de recherche et développement.

Services de personnalisation (OEM/ODM) : Nous savons que les conditions agricoles varient selon les régions. Pour le marché sud-coréen, nous proposons des options de personnalisation, notamment :

• Adaptation hydraulique : Réglage des pressions des soupapes pour correspondre aux débits hydrauliques spécifiques des tracteurs LS ou Daedong.

• Améliorations des pneus : Pneus de flottaison plus larges en option pour les rizières à boue profonde.

• Couleur et image de marque : Services de branding OEM pour les concessionnaires et les distributeurs.

Nous tenons Certification du système de gestion de la qualité ISO9001 et ont été reconnues comme entreprise nationale de haute technologie. Chaque presse à balles 9YG-2.24D subit un test rigoureux de fonctionnement continu de 48 heures avant expédition afin de garantir l'absence de défauts à la livraison.

11. Produits associés

11.1 Boîte de vitesses :

Modèles compatibles : EP-FK263 (presse à balles carrées), série EP-RC30 (presse à balles rondes, rapport de transmission 1:2, compatible avec arbre cannelé 6 cannelures de 35 mm).Application : Transmet la puissance de la prise de force au mécanisme de pressage, convient aux New Holland 630 ou John Deere 535. Paramètres : Couple > 500 Nm, économie de carburant 20%.Pourquoi choisir cette boîte de vitesses : dimensions personnalisables (réductibles à 250-300 mm), résistance aux contaminants visqueux (émanations de caoutchouc), protection IP65. Arbre de prise de force :Modèles compatibles : série EP-PTO (cannelure Z6 1-3/8″, longueur réglable 600-1200 mm).Application : Raccordement du tracteur à la transmission principale de la presse à balles, compatible avec le modèle 9YG-1.0C. Rendement de transmission du couple > 95%, compatible avec les brides SAE/EURO.Pourquoi il convient : Conception étanche, adapté aux opérations d’ensilage humide ; remplaçable par la série Weasler.

11.2 Chaînes et pignons :

Modèles compatibles : ANSI chaînes, avec pignon EP (pas 12,7-19,05 mm, diamètre du rouleau 10-12 mm).Application : Utilisé dans les convoyeurs à bande ou les mécanismes de liage, convient au transport de paille en balles carrées/rondes. Largeur : 25 à 40 mm, matériau : acier résistant à l’usure.Pourquoi il convient : Compatible avec les équipements Kobelco ou HF Group, réduit le risque de rupture de chaîne ; une option de qualité alimentaire est disponible pour l’ensilage.

11.3 Accouplements :

Modèles compatibles : Accouplement EP série 200 (couple adapté 500-1000 Nm).Application : Relie la boîte de vitesses au rouleau de la presse à balles, amortit les vibrations.Pourquoi il convient : Durabilité à grande échelle, compatible avec Bondioli et Pavesi.

11.4 Cylindre hydraulique:

Vérin hydraulique : Série EP-HC (alésage 50-100 mm, course 300-600 mm), adaptée au levage de balles.Roulements et joints : roulements 6208-2RS, durée de vie L10 > 10 000 heures, joint étanche à la poussière.Tableau de compatibilité : Entièrement interchangeable avec Comer 250T (couple correspondant, seulement 35% de moins au prix) ; la bride correspond au modèle de prise de force à 4 boulons nord-américain.* Avertissement : Les autres marques citées ci-dessus sont fournies à titre indicatif uniquement. Nous ne proposons aucun produit ni équipement original portant ces marques.Les paramètres varient selon les conditions de fonctionnement ; veuillez vous référer aux schémas. Il est recommandé de vérifier les dimensions de l’interface avant de procéder à la sélection.

12. Frequently Asked Questions (FAQ)

Q1. What is the estimated price for the 9GL-2.5 mower rake, including shipping to Incheon, South Korea?

A1. The FOB price fluctuates based on raw material costs, but we offer factory-direct pricing. For a precise CIF Incheon quote including customs clearance documentation, please contact our sales team via the “Get a Quote” button.

Q2. Which tractor horsepower is strictly required to operate the 9GL-2.9 heavy-duty trailed mower rake efficiently?

A2. To operate the 9GL-2.9 efficiently without straining your engine, we recommend a tractor with at least 35HP, though 50-55HP is ideal for handling hilly terrain and maintaining consistent PTO speed.

Q3. How does this reciprocating mower rake compare to a disc mower in terms of crop quality and leaf retention?

A3. Unlike disc mowers that shatter leaves due to high impact speed, our reciprocating sickle bar creates a scissor-like cut, preserving leaf integrity, which is crucial for high-protein feed like alfalfa.

Q4. Where can I buy replacement teeth or knife sections for this trailed mower rake if I am in Australia?

A4. We supply a comprehensive spare parts kit with every unit. Additionally, our components use standard international sizing, so you can find compatible knife sections at local agricultural supply stores or order directly from us via express air freight.

Q5. Can this machine function as a pull-behind rake for a tractor on uneven or rocky terrain safely?

A5. While it handles gentle slopes well, reciprocating cutters are sensitive to large rocks. However, our hydraulic lift system allows the operator to quickly raise the cutter bar over obstacles, preventing damage.

Q6. What is the Minimum Order Quantity (MOQ) for a customized OEM order of these mower rakes?

A6. For standard units, our MOQ is 1 set. For OEM customization (custom color, branding, or chassis modification), the MOQ is typically 5 sets to optimize production costs.

Q7. When is the best time to order to ensure delivery before the harvest season in the Northern Hemisphere?

A7. Due to high demand, we recommend placing orders 2-3 months before your harvest season begins. For Spring harvest, ordering in late Winter ensures your equipment arrives and is assembled in time.

Q8. How do I connect the hydraulic system if my tractor only has one rear hydraulic output valve?

A8. The 9GL series typically requires one set of hydraulic outlets for the lift cylinder. If your tractor lacks outlets, we can provide a manual mechanical lift conversion or a diverter valve kit as an option.

Q9. Is there a warranty for the gearbox and structural components of the 9GL-2.5 trailed mower?

A9. Yes, EVER-POWER provides a 12-month warranty on the main structural frame and the gearbox. Wear parts like knife sections and rake tines are excluded but are supplied as spares.

Q10. Do you provide installation manuals or video guides for assembling the machine upon arrival?

A10. Absolutely. We provide a detailed PDF manual in English (and other languages upon request) and a step-by-step video installation guide to ensure you can assemble the trailed mower rake easily.

Éditeur : PXY