توضیحات

1. 9GL Series Technical Engineering Specifications

| خیر. | مورد | واحد | مشخصات |

|---|---|---|---|

| 1 | نام مدل | / | 9GL-5.0/5.6 Towed Reciprocating Mower |

| 2 | نوع اتصال | / | Towed |

| 3 | Cutter Structure Type | / | Reciprocating |

| 4 | Cutting Width | متر | 5 |

| 6 | Grass Cutting Working Width | متر | 5.6 |

| 7 | Working Speed Range | کیلومتر در ساعت | 6~7 |

| 8 | بهرهوری | همم²/ساعت | Forage: 2.4-2.8, Hay: 3.0-3.6 |

| 9 | Average Cutting Height | میلیمتر | 60-70 |

| 10 | Matching Power | کیلووات | 30-60 |

| 11 | Power Output Shaft Speed | دور در دقیقه | 540 |

| 12 | وزن دستگاه | کیلوگرم | 1100 |

| 13 | Number of Connectors | رایانههای شخصی | 78 |

| 14 | Hitch Distance | میلیمتر | 71 |

| 15 | Machine Dimensions (L × W × H) | میلیمتر | 3860 × 5600 × 3000 |

| 16 | Operating Condition | میلیمتر | 3860 × 7600 × 850 |

| 17 | Number of Moving Blades | رایانههای شخصی | 68 |

2. Technical Architecture and Material Science

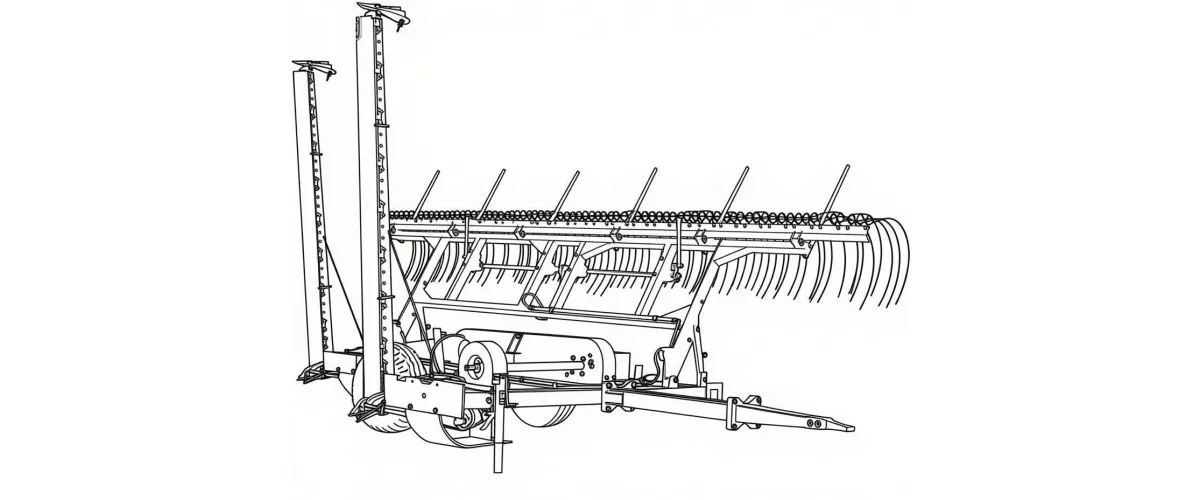

The 9GL-5.0 and 9GL-5.6 series represent the next evolution in integrated hay management equipment, consolidating the mowing and raking processes into a single tractor pass. As a premier Mower/Raker manufacturer, we have optimized these trailed units to maximize hectares-per-hour productivity for professional forage growers. Utilizing high-precision reciprocating mower technology, these machines provide a surgical cut that protects the stem’s vascular structure, promoting faster regrowth compared to traditional rotary systems.

By eliminating the need for a separate raking operation, livestock cooperatives in regions like Gangwon-do and Jeju Island can reduce fuel consumption by up to 35% and minimize soil compaction—a critical factor for sustainable land management in South Korea. These models are engineered for tractors ranging from 45 to 80 HP, featuring a robust folding chassis that ensures a 5.0m to 5.6m working width in the field while maintaining a safe, compact transport profile on public roads.

3. Market Trend Analysis: The Future of Integrated Forage Management

The global agricultural machinery landscape is rapidly pivoting toward “Multifunctional Integration” and “Soil-Centric Productivity.” In South Korea, the rising cost of labor and the consolidation of small family plots into larger commercial cooperatives have driven a 20% annual increase in the demand for wide-swath, 2-in-1 implements like the 9GL series. We are seeing a significant move away from separate mowing and raking passes toward a single-operator “One-Pass” philosophy.

This trend is not only about saving time but also about maximizing the “harvest window.” In humid climates like the Korean summer, reducing the field drying time by even 24 hours can be the difference between Grade-A forage and moldy silage. Furthermore, as “Smart Farming” initiatives grow in South Korea, there is an increasing reliance on implements that offer uniform windrows, which are essential for automated baling systems and high-capacity forage harvesters.

4. Working Principle:

The 9GL-5.0/5.6 Towed Reciprocating Mower combines mowing and raking in one machine, which greatly enhances operational efficiency. The machine is designed to be towed by a tractor and uses reciprocating mower technology. This mechanism works by converting the tractor’s PTO (Power Take-Off) rotational power into linear motion through a precision crank-rod system. The two independent cutter bars (each 2.5 meters wide) are driven simultaneously, providing a combined cutting width of 5.0 meters to 5.6 meters.

Precision cutting: The reciprocating system offers a clean, shearing cut, which is more efficient than rotary systems, preserving the vascular structure of the grass and promoting faster regrowth.

No need for raking: By combining both mowing and raking functions, the mower collects and gathers the cut forage into windrows simultaneously, eliminating the need for a separate raking operation.

Fuel efficiency: This integration of mowing and raking reduces fuel consumption by up to 35%, making it more energy-efficient compared to using separate machines.

Soil preservation: The design minimizes soil compaction, which is crucial for sustainable farming, especially in regions like Gangwon-do and Jeju Island where the terrain can be uneven.

Wide compatibility: The mower is compatible with tractors in the 45–80 HP range, ensuring flexibility across various farming operations. The hydraulic folding chassis allows the machine to have a compact transport profile, which complies with road transport regulations in South Korea.

5. Global Success

Client 2 Profile: Agricultural Contractor, Jeju Island, South Korea

Client Testimonial:

“The heat-treated manganese steel blades are durable and wear-resistant, even when encountering rocks. The hydraulic folding system ensures we can safely transport the equipment between fields without worrying about width restrictions. The 5.0-meter cutting width allows us to efficiently handle large areas. All in all, it’s a high-quality product, and I will continue to use it in my contracting business.”

Client 3 Profile: Agricultural Cooperative, Pyeongchang, South Korea

Client Testimonial:

“The 9GL-5.6 mower has been a game-changer for our cooperative. We’ve switched from traditional separate mowing and raking equipment to this integrated solution, and we’ve noticed a huge improvement in operational efficiency. The machine is easy to operate, allowing us to harvest natural grass or cultivated pastures on small slopes without worrying about soil compaction. The cutting quality is excellent, and the machine’s productivity fully meets expectations. We’ve reduced fuel consumption and can now complete harvesting in half the time.”

Client 4 Profile: Dairy Farm Manager, Gangwon Province, South Korea

Client Testimonial:

“As a dairy farm manager, I need to ensure we provide the highest quality feed for our cows. The 9GL-5.0 mower helps us achieve this goal. The productivity range of 2.4-2.8 hectares/hour is perfect for our farm’s needs. With its efficient cutting and minimal impact on the soil, this mower is ideal for our terrain. The clean cut provided by the reciprocating cutting technology helps maintain the nutritional value of the feed, and we’ve noticed our hay dries more evenly, which significantly improves the quality of our silage. This is a must-have for any serious dairy farmer.”

6. EVER-POWER Factory: Customization & Quality Assurance

تأسیسات تولیدی ما که در منطقه توسعه اقتصادی و فناوری هولونبویر واقع شده است، بیش از ... ۳۲۰۰۰ متر مربع و مجهز به دستگاههای برش لیزری CNC پیشرفته، خطوط جوش اتوماتیک و خطوط پوشش پودری الکترواستاتیک است. ما فقط یک مونتاژکار نیستیم؛ ما یک تولیدکننده جامع با قابلیتهای عمیق تحقیق و توسعه هستیم.

خدمات سفارشیسازی (OEM/ODM): ما درک میکنیم که شرایط کشاورزی بر اساس منطقه متفاوت است. برای بازار کره جنوبی، گزینههای سفارشیسازی از جمله موارد زیر را ارائه میدهیم:

• تطبیق هیدرولیک: تنظیم فشار سوپاپها برای مطابقت با جریانهای هیدرولیک تراکتور LS یا Daedong خاص.

• ارتقاء تایر: لاستیکهای شناور پهنتر اختیاری برای شالیزارهای گلی عمیق.

• رنگ و برندسازی: خدمات برندسازی OEM برای فروشندگان و توزیعکنندگان.

ما نگه میداریم گواهینامه سیستم مدیریت کیفیت ISO9001 و به عنوان یک شرکت ملی با فناوری پیشرفته شناخته شده است. هر دستگاه بستهبندی 9YG-2.24D قبل از ارسال، تحت آزمایش دقیق 48 ساعته مداوم قرار میگیرد تا از عدم وجود نقص در هنگام ورود اطمینان حاصل شود.

7. Related products

7.1 Gearbox:

مدلهای سازگار: EP-FK263 (بیلر مربعی)، سری EP-RC30 (بیلر گرد، نسبت انتقال ۱:۲، سازگار با شفت ۶ خار ۳۵ میلیمتری).کاربرد: انتقال قدرت PTO به مکانیزم عدلبندی، مناسب برای نیوهلند ۶۳۰ یا جان دیر ۵۳۵. پارامترها: گشتاور > ۵۰۰ نیوتن متر، صرفهجویی در مصرف سوخت ۲۰۱TP4T.چرا این گیربکس را انتخاب کنید: اندازه قابل تنظیم (قابل کاهش به ۲۵۰-۳۰۰ میلیمتر)، مقاوم در برابر آلایندههای چسبناک (بخار لاستیک)، درجه حفاظت IP65. شفت PTO:مدلهای سازگار: سری EP-PTO (اسپلین Z6 با قطر ۱-۳/۸ اینچ، طول قابل تنظیم ۶۰۰-۱۲۰۰ میلیمتر).کاربرد: اتصال تراکتور به درایو اصلی بیلر، مناسب برای نوع 9YG-1.0C. راندمان انتقال گشتاور >95%، سازگار با فلنجهای SAE/EURO.دلیل مناسب بودن: طراحی ضد آب، مناسب برای عملیات سیلوی مرطوب؛ قابل تعویض با سری Weasler

7.2 زنجیر و چرخ دنده ها:

مدلهای سازگار: ANSI زنجیربا چرخدنده EP-Sprocket (گام ۱۲.۷-۱۹.۰۵ میلیمتر، قطر غلتک ۱۰-۱۲ میلیمتر).کاربرد: مورد استفاده در تسمه نقاله یا مکانیزمهای اتصال، مناسب برای انتقال کاه به صورت مربع/گرد. عرض 25-40 میلیمتر، جنس فولاد مقاوم در برابر سایش.دلیل مناسب بودن: سازگار با تجهیزات کوبلکو یا گروه HF، کاهش خطر پارگی زنجیر؛ گزینه مناسب برای سیلوهای مواد غذایی موجود است.

7.3 Couplings:

مدلهای سازگار: سری EP-Coupling 200 (گشتاور تطبیقی ۵۰۰-۱۰۰۰ نیوتن متر).کاربرد: گیربکس را به غلتک عدلبندی متصل میکند، لرزش را کاهش میدهد.چرا مناسب است: دوام بالا در چرخههای کاری، سازگار با Bondioli و Pavesi.

7.4 سیلندر هیدرولیک:

سیلندر هیدرولیک: سری EP-HC (قطر داخلی ۵۰-۱۰۰ میلیمتر، کورس ۳۰۰-۶۰۰ میلیمتر)، مناسب برای بلند کردن عدل.بلبرینگ و آببند: بلبرینگ 6208-2RS، طول عمر L10 >10000 ساعت، آببند ضد گرد و غبار.جدول سازگاری: کاملاً قابل تعویض با Comer 250T (تطبیق گشتاور، فقط 35% با قیمت)؛ فلنج با الگوی PTO 4-Bolt آمریکای شمالی مطابقت دارد.* سلب مسئولیت: سایر نامهای تجاری ذکر شده در بالا صرفاً جهت نمایش ارائه شدهاند. ما محصولات یا تجهیزات اصلی دارای این نامهای تجاری را ارائه نمیدهیم.* پارامترها بسته به شرایط کاری متفاوت هستند؛ لطفاً به نقشههای واقعی مراجعه کنید. توصیه میشود قبل از انتخاب، ابعاد رابط را تأیید کنید.

8. Forage Harvesting Professional FAQ

Q1. What is the current commercial forage harvester price for the 5.6m trailed mower/rake delivered to Busan?

A1. The final investment for a 9GL-5.6 depends on your specific shipping logistics and customization needs. For commercial cooperatives in South Korea, we provide competitive high-capacity agricultural mower quotes that include international duties. Please click our “Get a Quote” button for a detailed commercial proposal within 24 hours.

Q2. Where can I find a reliable Trailed Mower/Rake supplier Korea that offers local maintenance support?

A2. We are a specialized industrial manufacturer with a dedicated export department serving the Korean agricultural sector. We partner with local technical service centers in Gyeonggi and Gangwon provinces to ensure your 9GL series receives genuine manganese steel spare parts and seasonal calibration.

Q3. How does the reciprocating mower technology benefit hay quality in humid Jeju Island pastures?

A3. Unlike rotary mowers that “beat” the grass, our reciprocating system uses a clean shearing cut. This preserves the plant’s moisture-conducting vessels, which allows the forage to dry more uniformly. In humid Jeju climates, this prevents internal fermentation and significantly improves the Grade-A haylage recovery rate.

Q4. What is the recommended tractor horsepower for pulling a 5.0m wide 9GL series mower/rake on hills?

A4. For optimal performance on sloped terrains typical of the Korean highlands, we recommend a tractor with at least 65 to 80 HP (48-58 kW). This ensures sufficient PTO torque to drive the 5.0m reciprocating cutter bar while maintaining steady towing stability at ground speeds of 5-8 km/h.

Q5. Are there specific Korea pasture harvesting regulations regarding the folding width of large agricultural implements?

A5. Yes, Korean regulations strictly limit the width of machinery on public agricultural roads. The 9GL-5.0/5.6 is designed with a high-clearance hydraulic folding system that brings its 5.6m working width down to a legal transport profile, allowing you to move between disconnected plots without special escort permits.

Q6. Which manganese steel alloy is used in your blades to resist stony volcanic soils in Jeju-do?

A6. We utilize a proprietary 65Mn heat-treated manganese alloy for all our reciprocating blades. This material is specifically chosen for its balanced hardness and fracture toughness, ensuring that even if the blade strikes a Jeju volcanic stone, it resists shattering and maintains a clean cutting edge.

Q7. How often should I inspect the reciprocating crank-rod system to maintain peak productivity?

A7. We recommend a daily visual inspection of the lubrication points during the harvest season. For every 100 operational hours, a thorough check of the drive belt tension and crank pin alignment is advised. This simple maintenance ensures the machine maintains its 4.5 hm²/h productivity rating for years.

Q8. Why should I choose an integrated mower-rake over two separate tractor-mounted implements?

A8. Choosing an integrated 9GL unit reduces your “Fuel-per-Hectare” cost by roughly 30%. More importantly, it halves the amount of heavy equipment passes on your pasture, which dramatically reduces soil compaction and promotes deeper root growth—a vital part of sustainable forage management equipment strategies.

Q9. Can your factory provide a high-capacity agricultural mower quote for custom tractor hitch standards used in Korea?

A9. Absolutely. While the 9GL series comes with a standard category 2 trailed hitch, we can customize the connection points to match specific LS Mtron or TYM tractor drawbar standards. We specialize in providing bespoke solutions that ensure a “Plug-and-Play” experience for your existing tractor fleet.

Q10. How does the 9GL-5.6 trailed mower/rake comply with South Korean land management construction laws?

A10. Under Korean MAFRA guidelines, agricultural machinery must minimize negative soil impact. Our 9GL series complies by utilizing high-flotation tires that spread the machine’s 1050 kg weight evenly. This prevents topsoil displacement and subsoil compaction, which is mandatory for maintaining soil fertility in permanent pasture zones.

تدوینگر: PXY

*سلب مسئولیت: سایر نامهای تجاری ذکر شده در بالا صرفاً جهت نمایش ارائه شدهاند. ما محصولات یا تجهیزات اصلی دارای این نامهای تجاری را ارائه نمیدهیم.