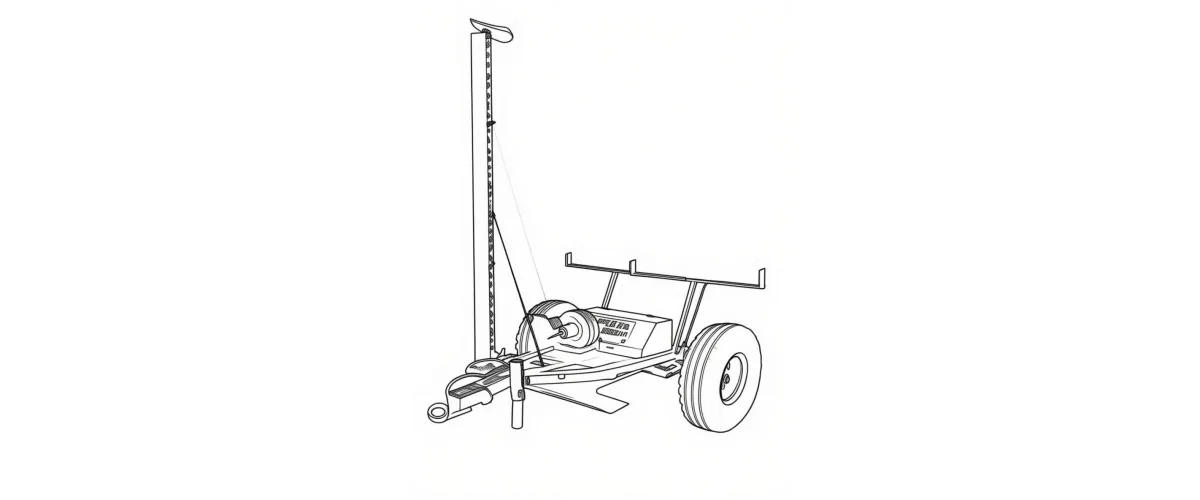

Descripción

1. 9GD-2.5 Technical Specifications

| No. | Artículo | Unidad | Especificación |

|---|---|---|---|

| 1 | Nombre del modelo | / | 9GD-2.5 Trailed Single-Blade Mower |

| 2 | Tipo de enganche | / | Arrastrado |

| 3 | Cutter Structure Type | / | Reciprocating |

| 4 | Cutting Width | metro | 2.5 |

| 5 | Matching Power Range | kW | 15-35 |

| 6 | Working Speed Range | kilómetros por hora | 6~10 |

| 7 | Number of Moving Blades | piezas | 34 |

| 8 | Dimensiones (L × An × Al) | mm | 2000×4300×950 |

| 9 | Power Output Shaft Speed | r/min | 540 |

| 10 | Average Cutting Height | mm | 50-70 |

| 11 | Productividad | hm2/h | 2.0-3.0 |

| 12 | Number of Operators | (persons) | 1 |

| 13 | Structure Weight | kilogramo | 490 |

2. Engineering Excellence: Principles and Scenarios

The working principle of the 9GD-2.5 relies on the mechanical conversion of rotational energy into high-speed linear reciprocating motion. The tractor’s PTO shaft transmits power to a primary drive pulley, which then activates the offset crank mechanism. This drives the cutter bar’s knives across stationary guards, creating a shearing effect similar to industrial scissors. This method is preferred in pasture management equipment in Korea because it minimizes soil disturbance and prevents the “shattering” of delicate forage leaves, preserving the nutritional content of the hay.

In terms of materials, the main frame is constructed from high-grade structural carbon steel, while the cutter bar features heat-treated manganese steel blades for exceptional wear resistance and impact durability against hidden field debris. This machine is optimized for various scenarios, including the management of natural mountain pastures, the harvesting of high-density planted forage, and even large-scale landscape maintenance in construction-reclaimed lands. Its towed configuration offers superior tracking and stability on uneven terrains compared to side-mounted alternatives, ensuring consistent cutting height across the entire 2.5-meter swath.

3. Universal Compatibility Matrix

| Tractor Brand | Estado de compatibilidad | PTO Requirement |

|---|---|---|

| LS Mtron / TYM / Daedong | High (Standard 3-Point Hitch) | 540 RPM |

| Kubota / Yanmar | High (Category I & II) | 540 / 720 RPM |

| John Deere / New Holland | Full Integration Ready | Standard 6-Spline |

4. Regulatory Compliance & Land Management Laws

5. Market Trend Analysis: The Future of Forage Harvesting

6. EVER-POWER Factory: Customization & Quality Assurance

Ubicada en la zona de desarrollo económico y tecnológico de Hulunbuir, nuestra planta de fabricación abarca más de 32.000 metros cuadrados Y estamos equipados con máquinas de corte láser CNC de última generación, líneas de soldadura automáticas y líneas de recubrimiento electrostático en polvo. No somos solo un ensamblador; somos un fabricante integral con una sólida capacidad de I+D.

Servicios de personalización (OEM/ODM): Entendemos que las condiciones agrícolas varían según la región. Para el mercado surcoreano, ofrecemos opciones de personalización que incluyen:

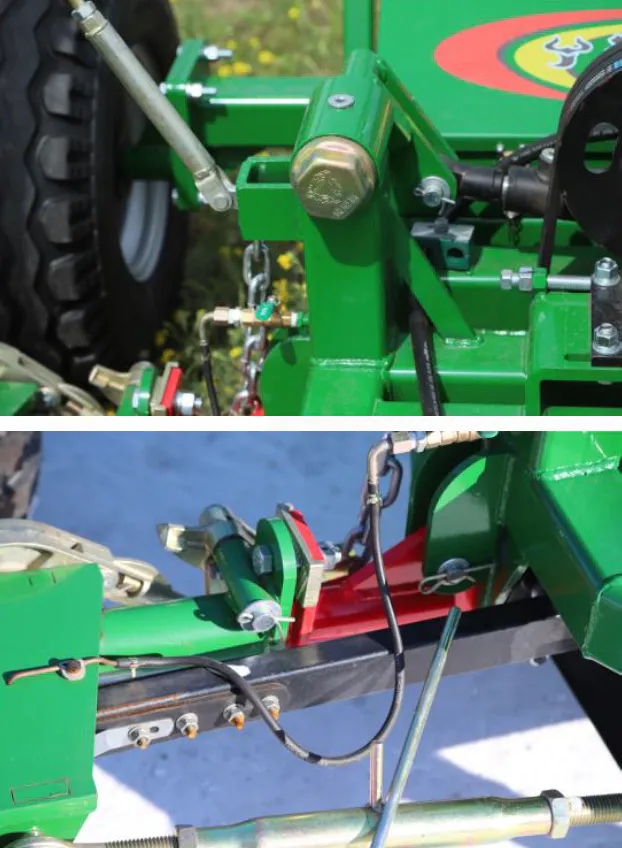

• Adaptación hidráulica: Ajuste de las presiones de las válvulas para que coincidan con los flujos hidráulicos de los tractores LS o Daedong específicos.

• Mejoras de neumáticos: Neumáticos de flotación más anchos opcionales para arrozales con lodo profundo.

• Color y marca: Servicios de marca OEM para concesionarios y distribuidores.

Nosotros sostenemos Certificación del Sistema de Gestión de Calidad ISO9001 y han sido reconocidas como Empresa Nacional de Alta Tecnología. Cada empacadora 9YG-2.24D se somete a una rigurosa prueba de funcionamiento continuo de 48 horas antes del envío para garantizar que no presente defectos a su llegada.

7. Related products

7.1 Gearbox:

Modelos compatibles: serie EP-FK263 (empacadora cuadrada), serie EP-RC30 (empacadora redonda, relación de transmisión 1:2, compatible con eje de 6 estrías de 35 mm).Aplicación: Transmite potencia de la toma de fuerza al mecanismo de empacado, adecuado para New Holland 630 o John Deere 535. Parámetros: Par > 500 Nm, ahorro de combustible 20%.¿Por qué elegir esta caja de cambios? Tamaño personalizable (reducible a 250-300 mm), resistente a contaminantes viscosos (humos de caucho), protección IP65. Eje de la TDF:Modelos compatibles: Serie EP-PTO (estrías Z6 de 1-3/8″, longitud ajustable 600-1200 mm).Aplicación: Conecta el tractor a la transmisión principal de la empacadora, compatible con el tipo 9YG-1.0C. Eficiencia de transmisión de par >95%, compatible con bridas SAE/EURO.Por qué es adecuado: Diseño resistente al agua, adecuado para operaciones de ensilaje húmedo; reemplazable con la serie Weasler.

7.2 Cadenas & Piñones:

Modelos compatibles: ANSI cadenas, con piñón EP (paso 12,7-19,05 mm, diámetro del rodillo 10-12 mm).Aplicación: Se utiliza en cintas transportadoras o mecanismos de atado, ideal para el transporte de paja en empacadoras cuadradas y redondas. Ancho: 25-40 mm, acero resistente al desgaste.Por qué es adecuado: Compatible con equipos Kobelco o HF Group, reduce el riesgo de rotura de la cadena; opción de grado alimenticio disponible para ensilaje.

7.3 Couplings:

Modelos compatibles: Acoplamiento EP serie 200 (adaptación de par 500-1000 Nm).Aplicación: Conecta la caja de engranajes al rodillo de enfardado, amortigua la vibración.Por qué es adecuado: Alta durabilidad en ciclos, compatible con Bondioli y Pavesi.

7.4 Cilindro hidráulico:

Cilindro hidráulico: Serie EP-HC (diámetro 50-100 mm, carrera 300-600 mm), adecuada para elevación de pacas.Cojinetes y sellos: Cojinetes 6208-2RS, vida útil L10 >10000 horas, sello a prueba de polvo.Tabla de compatibilidad: Totalmente intercambiable con Comer 250T (coincidencia de torque, solo 35% del precio); la brida coincide con el patrón de TDF de 4 pernos de América del Norte.* Aviso legal: Las demás marcas mencionadas se proporcionan únicamente con fines ilustrativos. No ofrecemos productos ni equipos originales que lleven estas marcas.* Los parámetros varían según las condiciones de trabajo; consulte los planos. Se recomienda confirmar las dimensiones de la interfaz antes de seleccionarla.

8. Frequently Asked Questions (FAQ)

Q1: How much does the 9GD-2.5 Towed Single-Blade Lawn Mower cost for delivery to Busan port?

A1: The **Reciprocating cutter bar mower price** for the 9GD-2.5 varies based on order volume and customization. Generally, for a single unit, the price is highly competitive for the Korean market. To get an exact quote including shipping and insurance to Busan or Incheon, please click our ‘Get a Quote’ button to speak with a sales representative.

Q2: Where can I find a reliable Towed Single-Blade Lawn Mower manufacturer that ships directly to South Korea?

A2: Jiujia Machinery is a direct-to-market manufacturer with extensive experience exporting to the South Korean agricultural sector. We handle all international logistics and provide direct factory support for the 9GD series, ensuring you avoid middleman markups while receiving genuine industrial-grade equipment.

Q3: What is the recommended tractor horsepower for operating the 9GD-2.5 lawn mower on sloped pastures?

A3: For the 9GD-2.5 model, the optimal power requirement is between 25 and 40 HP (18.4-30 kW)[cite: 1]. If you are operating in sloped regions like the Gangwon highlands, we recommend using a tractor at the higher end of that range (35-40 HP) to ensure consistent PTO speed and towing stability.

Q4: Which reciprocating blade material is best for high-moisture sudangrass harvesting in Korea?

A4: We utilize heat-treated manganese steel for all 9GD-2.5 cutter bars. This material is specifically chosen for its ability to maintain a sharp edge even when cutting high-moisture forage, preventing the “clogging” that often occurs with standard carbon steel blades in humid Korean summers.

Q5: How do I choose between the 9GD-2.5 and the upgraded version for my farm’s specific needs?

A5: The standard 9GD-2.5 is designed for maximum cost-efficiency and reliability using a traditional crank-rod system. [cite_start]If your priority is a proven, high-productivity workhorse (up to 2.0 hm²/h) [cite: 1] with simpler maintenance requirements, the standard 9GD-2.5 is the ideal choice for most commercial forage farms.

Q6: What are the maintenance requirements for the crank mechanism in the 9GD-2.5 lawn mower?

A6: To ensure longevity, the primary maintenance task is daily lubrication of the crank pin and connecting rod bearings. We also recommend checking the tension of the drive belt every 20 operational hours. [cite_start]These simple steps prevent mechanical wear and ensure your machine maintains its 5-8 km/h working speed[cite: 1].

Q7: Does Jiujia offer product customization for different tractor hitch standards used in Korea?

A7: Yes! While the 9GD-2.5 comes with a standard towed hitch, we can customize the connection points to match specific LS Mtron or Daedong tractor standards. We can also adjust the PTO spline configuration to ensure a seamless “plug-and-play” experience for your existing fleet.

Q8: When is the best time to replace the cutter bar guards on the 9GD-2.5?

A8: Guards should be inspected every season. If you notice a “tearing” rather than a “cutting” of the grass, or if the stationary edges have become rounded, it is time for a replacement. [cite_start]Maintaining sharp guards ensures you stay within the 30-80 mm cutting height range effectively[cite: 1].

Q9: What safety certifications does the 9GD-2.5 hold for international agricultural equipment markets?

A9: Our equipment is manufactured under ISO 9001 quality management systems and meets the essential safety requirements for international agricultural trade. We provide full technical documentation to assist with South Korean MAFRA safety audits and insurance requirements.

Q10: Why should I choose a towed single-blade mower over a standard rotary mower for livestock feed?

A10: Towed single-blade mowers use a reciprocating cut that preserves the stem’s vascular structure. This results in significantly higher forage quality and faster field drying times compared to rotary mowers, which can “beat” the grass and cause sap loss, especially in high-sugar crops like alfalfa.

Editor: PXY

*Descargo de responsabilidad: Las demás marcas mencionadas se proporcionan únicamente con fines ilustrativos. No ofrecemos productos ni equipos originales que lleven estas marcas.