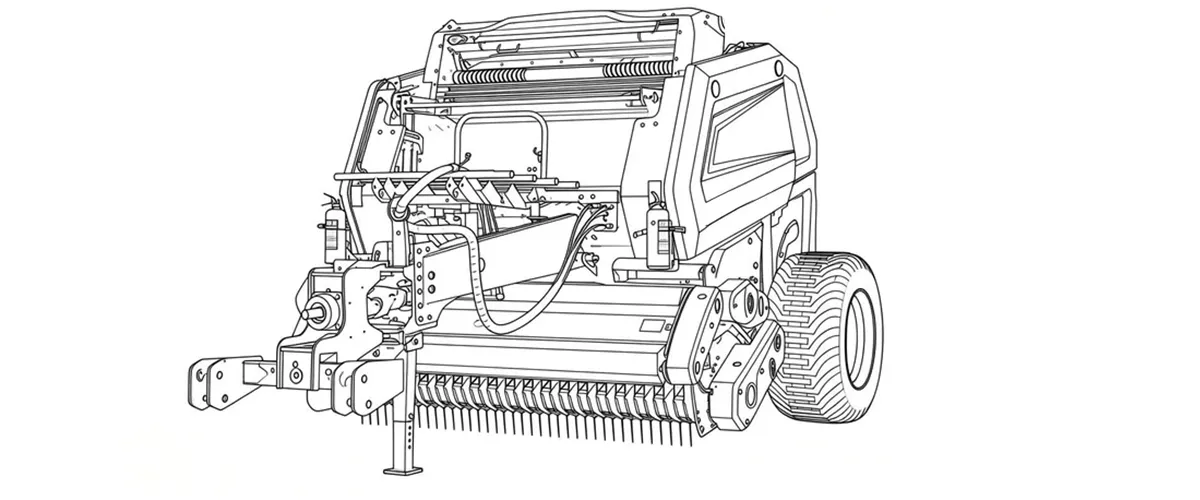

Empacadora redonda EP-9YG-2.24D S9000 Classic

The 9YG-2.24D Round Baler (S9000 Classic) is a high-performance, durable, and energy-efficient solution for efficient crop residue management. Designed for various crops such as straw, silage, and sugarcane, this baler features a robust roller compression system, advanced feeding mechanism, and superior maneuverability. Ideal for optimizing storage and transportation, it meets global environmental regulations and offers a reliable solution for large-scale agricultural operations.

1. EVER POWER Exclusive Specifications and Parameters S9000 Classic

| Parameter | Especificación |

|---|---|

| Nombre del modelo | 9YG-2.24D Round Baler (S9000 Classic) |

| Tipo de enganche | Traction Type (Drawbar) |

| Ancho de recogida | 2240 mm |

| Tipo de cámara de compresión | Roller Type (18 Rollers) |

| Bale Size (Diameter x Width) | Φ1300 x 1400 mm |

| Densidad de pacas | 100 - 200 kg/m³ |

| Productividad | 40 - 100 bales/hour |

| Matching Power | 55 - 100 kW (approx. 75 - 135 HP) |

| Peso estructural | 4312 kg |

| Velocidad de la toma de fuerza | 720 r/min |

| Working Dimensions (L x W x H) | 4470 x 3010 x 2370 mm |

| Método de encuadernación | Net Binding (Automatic) |

| Hydraulic Connection | H-Type Ferrule Joints (High Pressure) |

2. Redefining Harvest Efficiency: The S9000 Classic

3. Advantages of the 9YG-2.24D Round Baler (S9000 Classic)

3.1. Advanced Feeding Mechanism:

The 9YG-2.24D S9000 Classic employs an axial flow semi-forced feeding system. Unlike traditional models with cam tracks and retaining rings, this system significantly reduces power consumption while improving the feeding rate. It decreases the likelihood of material blockage, enhancing operational efficiency .

3.2. High Bale Density:

The round baler is equipped with 18 heavy-duty rollers, ensuring a consistent compression force that allows it to create high-density bales. This is particularly advantageous for optimizing transport logistics and storage space .

3.3. Superior Durability and Efficiency:

The dual-side heavy-duty 20A chains increase the baler's compression force, resulting in stronger and denser bales. The addition of a buffer cylinder in the rear chamber mitigates vibration during the closing cycle, enhancing the baler's lifespan and reducing wear .

3.4. Optimized Hydraulic System:

The hydraulic system features H-type ferrule joints, which increase pressure tolerance and speed up the opening and closing cycle times. Additionally, the use of these high-pressure components ensures zero leakage, aligning with environmental protection standards .

3.5. Flexible Operation:

The baler can handle a wide range of crop residues such as corn, wheat, soybeans, and pasture grass. It also supports a wide pickup width of 2240mm, ensuring efficiency during the collection phase .

3.6. Adaptability in Challenging Terrains:

The traction device features a newly designed double universal joint, allowing for better maneuverability in fields with tight turns. This mechanism also helps maintain a smooth operation during field headlands without disengaging the PTO, which decreases operator fatigue.

3.7. Improved Stability for Various Field Conditions:

The baler's structural stability is enhanced by the double-sided drive design in the rear chamber, which prevents the failure of the drive or axle during high-torque operations, especially in uneven field conditions .

4. Environmental Compliance & Global Agricultural Regulations

The shift from traditional field burning to biomass recovery is driven by increasingly stringent global environmental regulations. While industries like chemical processing focus on Regenerative Thermal Oxidizers (RTOs) to handle hazardous exhaust, the agricultural sector faces parallel mandates regarding Particulate Matter (PM2.5) reduction and Carbon Footprint management. In Australia, the National Environment Protection (Ambient Air Quality) Measure and various state-level EPA guidelines strictly regulate agricultural burning to prevent smoke haze and protect public health. Similarly, strict directives in the European Union (under the Common Agricultural Policy) and China (Law on the Prevention and Control of Atmospheric Pollution) have effectively banned straw burning, mandating mechanical harvesting and baling as the primary solution.

The 9YG-2.24D Round Baler serves as a critical tool for compliance with these legislative frameworks. By efficiently converting loose straw and residue into high-density bales, farmers can transform what was once a waste product requiring incineration into a valuable resource for biomass energy, animal feed, or paper manufacturing. Furthermore, the machine is designed in accordance with rigorous safety standards, including ISO 4254-1 (Agricultural machinery safety) and relevant Australian Standards for machinery guarding and hydraulic safety. The use of H-type ferrule joints in the hydraulic system ensures zero leakage, preventing soil contamination, which aligns with the Environment Protection and Biodiversity Conservation Act.

5. Global Trends in Forage Harvesting Technology

Application in Bazil

In Brazil, the utilization of biomass energy has become crucial in driving sustainable agriculture and green energy development. As a leading global agricultural machinery manufacturer, Ever Power provides efficient solutions for the Brazilian market, particularly in sugarcane residue management. Our 9YG-2.24D baler is specifically designed for efficiently baling sugarcane residue, compressing it into high-density round bales for easy transportation and storage.These baled sugarcane residues can not only be used as raw materials for animal feed but also converted into biomass energy, becoming an important alternative energy source. With the continuous development of biomass utilization technology, Ever Power's balers are helping farmers improve the recycling rate of sugarcane residue, reduce environmental pollution, and lay a solid foundation for renewable energy production. With Ever Power balers, Brazilian agricultural enterprises can not only reduce production costs and improve the overall utilization rate of crops but also meet the country's strict requirements for green energy and environmental regulations. Whether it's improving land use efficiency or achieving zero-waste sustainable development, Ever Power provides strong technical support to help Brazilian agriculture move towards a more environmentally friendly and efficient future.

6. Customer Success Story:

“The S9000 Classic has improved our harvesting efficiency. Our productivity has increased significantly, and the bale density is much higher. The roller-type compression chamber ensures we can handle many different types of crops, which I really appreciate. I highly recommend this machine!”

— John, Farm Manager, Queensland, Australia

“As a family business, we rely on machinery that can handle the challenges of different crops. The advantage of the 9YG-2.24D round baler is that it can handle both dry hay and high-moisture silage, making it an indispensable part of our operation. The net wrapping system has greatly improved efficiency. And the classic model is even more reliable.”— Sarah, Victoria, Australia

“We have been using the S9000 for several seasons now, and its performance has been consistently reliable. The compact design reduces maintenance requirements, making our operations smoother. Furthermore, whenever we have encountered issues requiring parts or technical support, Ever Power's customer service has been excellent, and the after-sales service is fantastic.”— Daniel, Equipment Manager, Northern Territory, Australia

“It's robust and durable, and performs perfectly even in our sandy soil conditions. The long-lasting chain system was a key factor in our purchase decision.”— Mark, Operations Supervisor, New South Wales, Australia

“Integrating Ever Power's RTO technology into our baling process was one of the best decisions I've ever made. This baler has also far exceeded our expectations in terms of speed.”— Leo, Farmer, Melbourne, Australia

7. Compatibility & Performance Comparison

| Feature | EP 9YG-2.24D (S9000) | Standard Competitor Baler | Advantage |

|---|---|---|---|

| **Transmission** | Double-sided 20A Heavy Duty Chain | Single-sided standard chain | Balanced load, higher torque, longer lifespan. |

| **Traction Device** | Double Universal Joint + Safety Torque | Standard PTO Shaft | Smoother turning in small fields; overload protection. |

| **Hydraulic Fittings** | H-Type Ferrule (High Pressure) | Standard O-Ring Seal | Zero leakage, faster open/close cycle times. |

| **Pickup Mechanism** | Axial Flow (No Cam Track) | Cam Track System | Fewer moving parts, less maintenance, higher speed. |

| **Rear Chamber** | Equipped with Buffer Cylinder | Mechanical Stop | Reduces vibration shock, protects frame integrity. |

8. Application Scenarios

Case Study 1: Application in Large-Scale Hay Export Farms in the United StatesIn large-scale hay export farms in the United States, balers significantly improved bale density and transportation efficiency, meeting the demand for over 100,000 tons of hay annually. The EP-FK263 square baler, with a torque range of 500-2000 Nm and compatible with John Deere interface standards (SAE flange), achieved bale densities >200 kg/m³ and 20% fuel savings in applications in California or Texas farms. According to USDA data, US hay exports reached 1.5 million tons in 2024, driving the demand for mechanization.

Case Study 2: Application in China's Straw Comprehensive Utilization Industrial ParksIn China's straw comprehensive utilization industrial parks, balers optimized the biomass energy supply chain, processing over 500,000 tons of straw annually. The 9YG-1.0C round baler, with a power range of 30-120 HP and a speed ratio of 1:2-1:4, compatible with Kubota spline shafts (35mm 6-key), achieved a bale diameter of 1.0m and a 30% increase in efficiency in parks in Shandong and Henan provinces. According to the National Bureau of Statistics, China's annual straw production is 800 million tons, driving mechanization subsidy policies (agricultural machinery purchase subsidies >20%).

Case Study 3: Application in Brazilian Sugarcane Residue Energy FarmsIn Brazilian sugarcane residue energy farms, balers improved the efficiency of the bioethanol supply chain, with an annual output of over 300,000 tons of residue. With a power range of 20-100 HP and a speed ratio of 1:1-1:5, applications in São Paulo state achieved uniform bale density and compatibility with Case IH interfaces. Data from the Brazilian Ministry of Agriculture shows that Brazil is the world's largest producer of sugarcane (790 million tons/year), driving the demand for residue recycling.

Case Study 4: Application in German Precision Agriculture Organic FarmsIn German precision agriculture organic farms, balers ensured compliance with EU organic standards, processing over 100,000 tons of organic straw annually. The EP-PTO series gearbox, with DIN 6 precision and a speed ratio of 1:1.5-1:3, achieved precise baling in applications in Bavaria. EU statistics show that organic farmland accounts for 20% of Germany's total farmland, driving the demand for efficient machinery.

Case 5: Application in a Canadian Grain Straw Biomass Power PlantIn the Canadian grain straw biomass power plant, balers support the renewable energy chain, supplying >250,000 tons of straw annually. EP-Coupling 200 series couplings are used, with a torque of 500-1000 Nm, applied in Ontario, providing vibration damping. Data from the Canadian Ministry of Agriculture shows a CAGR of 6% for biomass demand.

Case 6: Large-Scale Wheat Straw Harvesting Application in RussiaIn large-scale wheat straw harvesting in Russia, balers improved export efficiency, with an annual output exceeding 400,000 tons. EP-Sprocket sprockets are used, with a pitch of 12.7mm, applied in Rostov Oblast, enabling cold-resistant operation. A report from the Russian Ministry of Agriculture shows that Russia is the world's third-largest wheat producer (80 million tons/year).

Case 7: Application in a South African Corn Stover Feed Processing PlantIn a South African corn stover feed processing plant, balers optimized the livestock supply chain, processing >180,000 tons annually. EP-HC hydraulic cylinders are used, with a bore diameter of 50-100mm, applied in Gauteng province, improving efficiency. Data from the South African Ministry of Agriculture shows a corn production of 12 million tons/year, driving feed demand.

Case 8: Application in a Thai Rice Straw Biofuel FarmIn a Thai rice straw biofuel farm, balers facilitated the renewable energy transition, with an annual rice straw volume of >120,000 tons. EP-PTO shafts are used, with a length of 600-1200mm, applied in the Central Plains, providing waterproof transmission. A report from the Thai Ministry of Agriculture shows a rice production of 20 million tons/year, with an 8% growth in biofuel demand.

9. Manufacturing Excellence & Customization Services

9.1. Requiere un esquema de colores específico para su flota (rojo, verde o personalizado).

9.2. Chasis reforzado para terrenos rocosos

9.3. Adaptadores de enganche para diferentes marcas de tractores (John Deere, Case IH, New Holland, Kubota). Nuestro centro de I+D puede satisfacer sus necesidades.

9.4. Nuestra capacidad para intercambiar sistemas de recolección, entre dientes de resorte estándar y garras de martillo para tallos de maíz, demuestra nuestro compromiso con la versatilidad. Sometemos cada unidad a rigurosas pruebas para garantizar que cumpla con las normas de calidad ISO 9001 antes de salir de nuestra fábrica.

Certificados y honores:

· Certificación ISO 9001

· Certificado Nacional de Empresa de Alta Tecnología

· Derecho de Operación de Importación y Exportación por Cuenta Propia

· Certificación CE

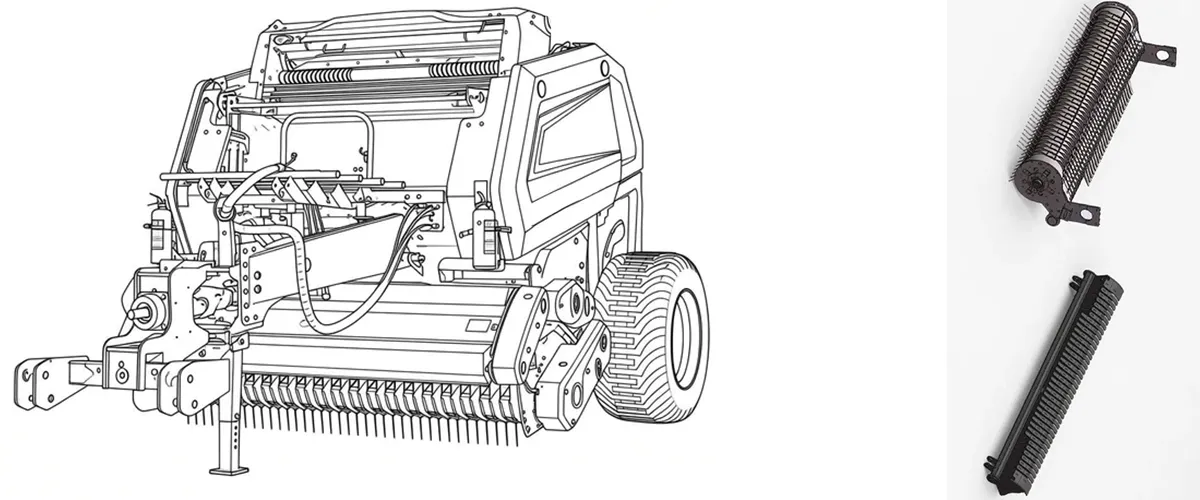

10. Componentes reemplazables

10.1 Caja de cambios:

10.2 Cadenas & Piñones:

10.3 Acoplamientos:

10.4 Cilindro hidráulico:

11. Preguntas frecuentes

P1. ¿Cómo beneficia el eje de transmisión de doble junta universal del S9000 la operación en campos pequeños o irregulares?

A1. La junta universal doble especializada permite ángulos de giro más cerrados sin desconectar la toma de fuerza, lo que evita que la transmisión se atasque y reduce significativamente la fatiga del operador durante los giros en cabeceras.

P2. ¿Cuál es la vida útil esperada de las cadenas 20A de servicio pesado en comparación con las cadenas estándar utilizadas en otras empacadoras?

A2. Nuestras cadenas reforzadas 20A están diseñadas para soportar cargas de torque más altas que las cadenas 30%, con una duración típica de 2 a 3 temporadas más que las cadenas estándar en condiciones de empacado de alta densidad.

P3. ¿Esta empacadora puede procesar cultivos de ensilado con alto contenido de humedad o es solo para heno y paja secos?

A3. Sí, la cámara de compresión de rodillos es excelente para el ensilado. Recomendamos ajustar la densidad y usar una malla de alta calidad para garantizar condiciones anaeróbicas para la fermentación.

P4. ¿El 9YG-2.24D es compatible con modelos de tractores más antiguos que podrían tener menor presión hidráulica?

A4. La unidad requiere un mínimo de 55 kW (75 HP). Si bien las juntas tipo H soportan alta presión, el sistema es adaptable. Consulte a nuestros técnicos sobre el caudal hidráulico específico de su tractor.

P5. ¿Dónde puedo conseguir piezas de repuesto para el mecanismo de recogida si me encuentro en Australia Occidental?

A5. Hemos establecido una red logística optimizada. Las piezas de desgaste comunes, como los dientes de recogida, se almacenan regionalmente o se pueden enviar por avión directamente desde nuestra fábrica en un plazo de 5 a 7 días hábiles.

P6. ¿Cómo se compara el sistema de atado con red con el de atado con hilo en términos de integridad y velocidad de la paca?

A6. El atado con red es significativamente más rápido (10-15 segundos/paca) que el atado con hilo, lo que aumenta el rendimiento por hora. Además, ofrece mayor protección contra la intemperie y mantiene la forma durante el transporte.

P7. ¿Cuál es el período de garantía de la caja de cambios principal y los componentes estructurales para compradores internacionales?

A7. Ofrecemos una garantía internacional estándar de 12 meses para la caja de cambios principal y el chasis, con soporte técnico en línea y guías en video para la resolución de problemas y reparaciones.

P8. ¿La empacadora cilíndrica 9YG-2.24D puede procesar grandes volúmenes de paja o ensilado?

A8: Sí, la empacadora redonda 9YG-2.24D puede manipular grandes volúmenes de paja, ensilado y otros materiales fibrosos. Entre los cultivos que se pueden empacar se incluyen trigo, arroz, algodón, pastos, ensilado de maíz, alfalfa, caña de azúcar y carrizo.

P9: ¿La empacadora redonda 9YG-2.24D es adecuada para su uso en terrenos difíciles y campos pequeños?

A9: Sí, la empacadora es ideal para campos pequeños y terrenos difíciles. Está equipada con una junta universal doble para una mejor maniobrabilidad y un funcionamiento más suave en los giros de cabecera. Esta función ayuda a evitar la desconexión de la toma de fuerza, algo común en terrenos estrechos e irregulares, lo que garantiza un funcionamiento continuo sin interrupciones.

P10: ¿Qué hace que la empacadora redonda 9YG-2.24D sea más eficiente energéticamente en comparación con otras empacadoras?

A10: La empacadora de pacas redondas 9YG-2.24D logra una eficiencia energética superior gracias a su mecanismo de alimentación semiforzada de flujo axial y su sistema hidráulico regenerativo. Estos sistemas reducen la necesidad de potencia adicional durante la operación, y las robustas cadenas de 20 A distribuyen el par uniformemente, reduciendo la tensión en la máquina y el consumo de combustible, a la vez que mantienen un alto rendimiento.

*Descargo de responsabilidad: Las demás marcas mencionadas se proporcionan únicamente con fines ilustrativos. No ofrecemos productos ni equipos originales que lleven estas marcas.

Editor: PXY