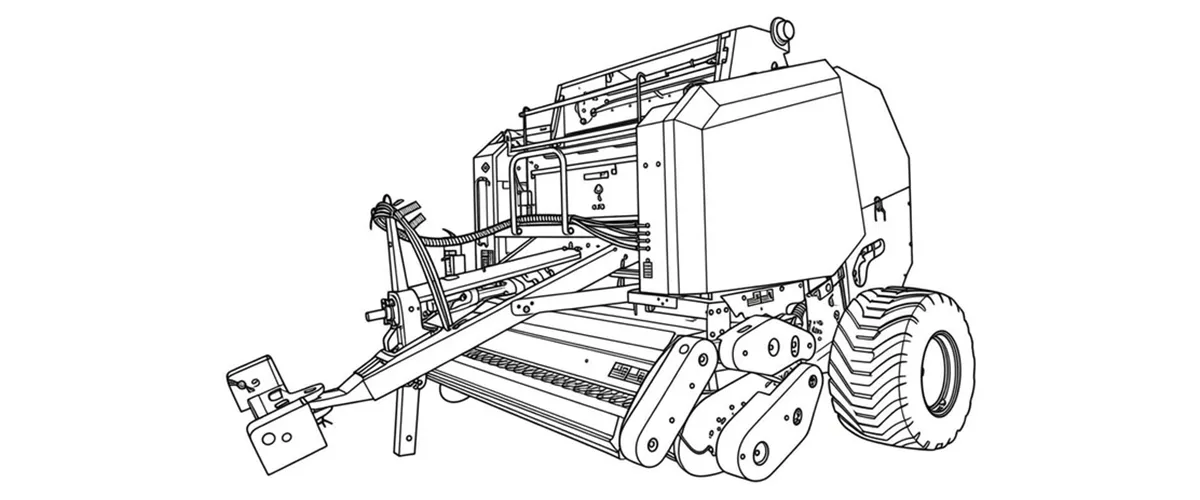

EP-9YG-2.24D Rundballenpresse

The 9YG-2.24D Round Baler utilizes a proprietary “Axial Flow” semi-forced feeding mechanism that eliminates traditional cam tracks, significantly reducing maintenance needs while doubling operational efficiency. Designed with a 2240mm pickup width and an 18-roller compression system, it delivers high-density cylindrical bales ideal for the rigorous demands of rice straw and corn stalk collection in markets like South Korea. This heavy-duty agricultural implement supports soil conservation compliance by efficiently clearing crop residues, making it a sustainable choice for modern livestock and biomass industries.

High Density • Axial Flow Feeding • Intelligent Net Binding • Optimized for South Korean Terrain

1. Technical Specifications: 9YG-2.24D Round Baler

Data based on standard engineering tests. Actual performance may vary depending on crop conditions.

| NEIN. | Artikel | Einheit | Spezifikation |

|---|---|---|---|

| 1 | Modellname | / | 9YG-2.24D Round Baler |

| 2 | Anhängertyp | / | Trailed |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure Type | / | Tine Pickup |

| 5 | Feeding Mechanism Structure | / | Feeding Rotor + Roller Type |

| 6 | Compression Chamber Type | / | Roller Chamber |

| 7 | Compression Chamber Width | mm | 1400 |

| 8 | Compression Chamber Diameter | mm | Φ1200 |

| 9 | Number of Roller Working Components | Stück | 18 (rollers) |

| 10 | Roller Diameter | mm | Φ222 |

| 11 | Baling Method | / | Net Wrap |

| 12 | Required Power | kW | 55–100 |

| 13 | Structural Weight | kg | 3922 |

| 14 | PTO Output Shaft Speed | r/min | 720 |

| 15 | Dimensions (L × W × H) | mm | 4110 × 3010 × 2450 (working condition) |

| 16 | Forage Density Control | / | Sensor-Controlled |

| 17 | Bale Size (Diameter × Width) | mm | Φ1300 × 1400 |

| 18 | Bale Density | kg/m³ | 100–200 |

| 19 | Produktivität | bale/h | 40–100 |

| 20 | Wheelbase | mm | 2600 |

| 21 | Operating Speed | km/h | 5–35 |

| 22 | Net Wrap Specification | M | 2000 × 1.4 / roll |

2. Advantages of 9YG-2.24D Round Baler

The 9YG-2.24D Round Baler represents the pinnacle of agricultural engineering, specifically designed to address the complex harvesting needs of diverse crops such as corn, rice, wheat, soybean straw, and natural pasture grass.

Unlike traditional models that suffer from frequent mechanical blockages and power inefficiencies, this advanced model integrates a revolutionary "Axial Flow" semi-forced feeding mechanism coupled with a cam-less, guard-ring-less pickup system.

This proprietary technology, developed with exclusive intellectual property rights, fundamentally transforms the material flow dynamics within the machine. By eliminating the conventional cam track, we have significantly reduced the number of moving parts, which directly translates to lower maintenance costs and reduced kinetic energy loss during operation. This is particularly critical for markets like South Korea, where the harvest windows for rice straw are tight, and equipment reliability is paramount. The machine boasts a massive 2240 mm pickup width, ensuring that wide swathes are collected cleanly in a single pass, enhancing field efficiency by nearly double compared to older generations.

Engineered for high-density baling, the 9YG-2.24D utilizes an 18-roller compression chamber that forms bales with densities ranging from 100 to 200 kg/m³. This high-density capability is crucial for maximizing storage space and reducing transportation costs, a significant factor for commercial forage providers and livestock farms managing large herds. The machine's structural integrity is supported by a robust chassis with a structural mass of 3922 kg, ensuring stability even when operating on uneven terrain or slopes often found in East Asian agricultural landscapes. Furthermore, the integration of sensor-controlled density management allows operators to precisely adjust the bale tightness based on the moisture content and type of crop, ensuring optimal fermentation conditions for silage or perfect dryness for dry hay storage. The automated net wrap system further streamlines the process, wrapping bales in seconds to protect nutrient quality immediately after formation.

3. Global & Regional Market Trend Analysis: The Shift to Intelligent Baling

The global agricultural machinery market is currently witnessing a significant paradigm shift towards "Smart Farming" and biomass utilization, with a specific emphasis on crop residue management.

In regions like South Korea, Japan, and China, the prohibition of open-field straw burning due to environmental regulations (fine dust and carbon emission controls) has created a surging demand for high-efficiency balers. Farmers are no longer just looking for a machine to clear the field; they require equipment that can turn agricultural waste (rice straw, corn stover) into a valuable commodity for biomass energy plants or TMR (Total Mixed Ration) feed for the cattle industry.

The 9YG-2.24D addresses this trend by offering a "zero-waste" pickup capability. The trend is moving away from square balers to round balers for silage production because round bales naturally shed water and facilitate the fermentation process required for high-quality animal feed.

Furthermore, the trend towards tractor horsepower escalation in the Asia-Pacific region aligns perfectly with the 9YG-2.24D’s power requirements. As farms consolidate and mechanize, the average tractor size is increasing, making the 55-100 kW (75-135 HP) power requirement of this baler ideal for modern medium-to-large scale operations.

We are also seeing a clear preference for machines with lower maintenance downtime. The industry is moving away from complex cam-track systems that require daily greasing and frequent bearing replacements, towards the low-maintenance, cam-less technology featured in our 9YG-2.24D. This shift is driven by labor shortages in the agricultural sector globally; fewer operators mean that each machine must be more reliable and faster. With a productivity rate of 40 to 100 bales per hour, this model is positioned at the forefront of this high-efficiency trend, enabling contractors to complete jobs faster and maximize profitability during the limited harvest season.

4. Engineering Excellence: Working Principle & Material Science

Innovative Axial Flow Mechanism

The core competitive advantage of the 9YG-2.24D lies in its Axial Flow Semi-Forced Feeding System. Traditional balers often struggle with crop transition from the pickup to the chamber, leading to "hairpinning" or blockages. Our system utilizes a specialized dial tine roller combined with a secondary roller to create a smooth, accelerated crop flow. This active feeding ensures that even wet, heavy crops like green rice straw or silage are forced into the compression chamber without hesitation. The compression chamber itself features 18 high-strength steel rollers (Φ 222 mm), which rotate to tumble the crop into a consistent geometric spiral, forming a bale with a soft core for aeration and a dense outer shell for weather protection.

Heavy-Duty Material Specification

Durability is non-negotiable in industrial agriculture. The 9YG-2.24D chassis and rollers are constructed from Q345B High-Strength Low-Alloy Steel, offering superior resistance to structural fatigue compared to standard carbon steel. The gears and transmission components undergo advanced Carburizing and Quenching heat treatment to achieve a surface hardness of HRC 58-62, ensuring the gearbox can withstand the high torque loads required for high-density baling. The pickup tines are made from 65Mn Spring Steel, heat-treated to provide the elasticity needed to glide over rocks and uneven ground without snapping, minimizing downtime and replacement costs.

5. Tractor & Component Compatibility Guide

The 9YG-2.24D is designed with universal interfaces to ensure seamless integration with major global tractor brands and standard agricultural components.

| Kategorie | Compatible Brands / Standards | Replacement Notes |

|---|---|---|

| Tractor Brands (75-135HP) |

| Requires standard 3-point hitch (Category II) or Drawbar towing. Hydraulic output must meet continuous flow requirements. |

| PTO Shaft / Driveline | Standard 6-spline 1-3/8" (540/720 RPM input) | Compatible with standard wide-angle PTO shafts from Walterscheid or Bondioli & Pavesi replacements. |

| Hydraulic Interface | Standard ISO 1/2" Quick Couplers | Requires 2 sets of double-acting valves on the tractor. |

| Binding Net | Standard 1.4m width Net Wrap (Tama, Novatex, etc.) | Universal fit for standard roll diameters. |

6. Regulatory Compliance

South Korea (Focus Market)

Fine Dust Reduction & Straw Bans: The South Korean Ministry of Environment and Ministry of Agriculture, Food and Rural Affairs (MAFRA) strictly enforce bans on open-field straw burning to combat fine dust pollution. The 9YG-2.24D is an essential tool for compliance, allowing farmers to collect 100% of residues.

Subsidies (NACF/Nonghyup): This equipment meets the technical standards often required for government-subsidized agricultural machinery loans and grants available through local Agricultural Technology Centers.

Soil Compaction Laws: With a structured mass of 3922kg and wide flotation tires (Wheel Track 2600mm), this baler distributes weight effectively, minimizing deep soil compaction in wet paddy fields, adhering to sustainable land management guidelines.

International Standards

ISO 11783 (ISOBUS): Our sensors and electronic controls are designed to be compatible with modern tractor interface standards.

Safety Regulations: The machine includes necessary safety guards and emergency stop mechanisms compliant with EU and North American agricultural machinery safety directives.

7. EVER-POWER Factory: Customization & Quality Assurance

Unser Produktionswerk befindet sich in der Wirtschaftsentwicklungszone Hulunbuir und erstreckt sich über 32.000 Quadratmeter Wir sind mit modernsten CNC-Laserschneidmaschinen, automatischen Schweißanlagen und elektrostatischen Pulverbeschichtungsanlagen ausgestattet. Wir sind nicht nur ein Montagebetrieb, sondern ein Komplettanbieter mit umfassenden Forschungs- und Entwicklungskapazitäten.

Anpassungsdienstleistungen (OEM/ODM): Wir verstehen, dass die landwirtschaftlichen Bedingungen je nach Region variieren. Für den südkoreanischen Markt bieten wir unter anderem folgende Anpassungsmöglichkeiten an:

• Hydraulische Anpassung: Ventildrücke an die spezifischen Hydraulikflüsse von LS- oder Daedong-Traktoren anpassen.

• Reifen-Upgrades: Optionale breitere Breitreifen für tief schlammige Reisfelder.

• Farbe & Branding: OEM-Branding-Services für Händler und Distributoren.

Wir halten ISO9001 Qualitätsmanagementsystem-Zertifizierung und wurden als nationales Hightech-Unternehmen anerkannt. Jede Ballenpresse des Typs 9YG-2.24D wird vor dem Versand einem strengen 48-stündigen Dauerbetriebstest unterzogen, um sicherzustellen, dass sie bei der Ankunft fehlerfrei ist.

8. Customer Success Story: Efficiency Gains in Jeollabuk-do

"I’ve been using the 9YG-2.24D Round Baler for my rice fields. The 2240mm pickup width really saves time, and the axial flow feeding system works wonders even with wet straw. Plus, the machine’s super easy to maintain compared to the old models. Highly recommend it!"

---John from South Korea

"We’ve been working with this baler for a few months now, and it’s proven itself on tough slopes. The heavy-duty chains and rollers give us solid performance, even when we’re dealing with corn stover and wheat straw. Plus, the bale density control is spot-on!"

---Sungmin from Jeollabuk-do

"The 9YG-2.24D is exactly what we needed for our operation. It’s built like a tank and can handle even the toughest crops. The high-density bales make a huge difference when it comes to transporting. It's easy to set up and operate, too!"

---Jinwoo from Busan

"I’ve been using this baler for a couple of months, and the performance is fantastic. The 18-roller compression chamber makes sure our bales are dense and well-formed. Plus, it's much less time-consuming than traditional methods. Worth every penny!"

---Minseok from Gyeonggi-do

"I was impressed from the first use. The baler is extremely efficient, even in challenging conditions like wet or heavy crops. I love that it doesn’t require constant maintenance like some other models I’ve used. It’s really increased productivity on our farm."

---Jiwon from Daegu

9. Application Scenarios

9.1. Hay Baling for Livestock Feed

Application: Round balers are most commonly used for collecting and compressing hay for livestock feed. This is especially prevalent in regions with large-scale cattle, sheep, and dairy farms. The baler forms dense bales that are easy to transport and store for the winter months, providing a steady feed source.

Example: Used extensively in the U.S., Argentina, and Australia for large-scale hay production.

9.2. Silage Production

Application: Round balers are ideal for creating silage from crops like corn, alfalfa, and grass. The high-density bales help preserve the crop's nutrients for livestock feed, especially during the colder months.

Example: Widely used in Europe (e.g., France, Germany) and North America to handle wet silage crops.

9.3. Straw Baling Post-Harvest

Application: After grain crops like wheat or barley are harvested, round balers are used to collect straw, which can be sold as bedding for animals or used for bioenergy production. The round bale system reduces handling time and labor costs.

Example: Common in the U.K., Canada, and parts of Eastern Europe, where straw is a valuable commodity for bedding and bioenergy.

9.4. Corn Stover Baling

Application: Corn stover (the leaves, stalks, and husks of corn plants) is often collected by round balers for use in bioenergy production or as a bedding material. Corn stover is a major source of biomass for bioenergy, especially in the U.S. and Brazil.

Example: Used in the Midwest U.S., where corn is a primary crop, and there is high demand for biomass.

9.5. Rice Straw Collection

Application: After rice harvest, round balers are employed to collect rice straw, a byproduct that can be used for animal feed or composting. The baler’s high-density bale formation ensures easy storage and transportation.

Example: Commonly used in Asia, including India, China, and Thailand, where rice straw is abundant and used for various purposes.

9.6. Peanut Vine Baling

Application: After peanuts are harvested, the vines are often baled for animal feed or used for organic composting. The round baler’s large pickup width and efficient baling help reduce the time and effort needed for collecting these residues.

Example: Widely used in peanut-growing areas like the U.S. Southeast and India.

9.7. Bioenergy Biomass Baling

Application: Round balers are used to collect various crop residues like grass, straw, and cornstalks for bioenergy production. These residues are compressed into high-density bales and then transported to biomass power plants for energy generation.

Example: Used in countries with advanced bioenergy industries like Sweden, Germany, and the U.S.

9.8. Reed and Grass Baling for Bioenergy and Bedding

Application: In coastal areas or wetlands, reed and other grasses are baled for use in energy production or as bedding material for animals. These plants are often abundant and provide a cost-effective solution for biomass fuel.

Example: Used in the Netherlands and the Baltic region, where reed beds and wetland grasses are abundant.

10. Related products

10.1 Gearbox:

Kompatible Modelle: EP-FK263 (Quaderballenpresse), EP-RC30-Serie (Rundballenpresse, Übersetzungsverhältnis 1:2, kompatibel mit 35-mm-6-Zahn-Welle).Anwendung: Überträgt Zapfwellenleistung auf die Ballenpresse, geeignet für New Holland 630 oder John Deere 535. Parameter: Drehmoment > 500 Nm, Kraftstoffersparnis 20%.Warum dieses Getriebe wählen? Anpassbare Größe (reduzierbar auf 250–300 mm), beständig gegen viskose Verunreinigungen (Gummidämpfe), Schutzart IP65. Zapfwelle:Compatible Models: EP-PTO series (1-3/8" Z6 spline, adjustable length 600-1200mm).Anwendung: Verbindet Traktor mit dem Hauptantrieb der Ballenpresse, geeignet für Typ 9YG-1.0C. Drehmomentübertragungseffizienz >95%, kompatibel mit SAE/EURO-Flanschen.Why it's suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.

10.2 Ketten & Kettenräder:

Compatible Models: ANSI #50/#60 Ketten, mit EP-Kettenrad (Teilung 12,7-19,05 mm, Rollendurchmesser 10-12 mm).Anwendung: Einsatz in Förderbändern oder Bindemechanismen, geeignet für den Transport von Stroh in Quader-/Rundballenpressen. Breite 25–40 mm, verschleißfestes Stahlmaterial.Why it's suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.

10.3 Couplings:

Kompatible Modelle: EP-Kupplung Serie 200 (Drehmomentanpassung 500-1000 Nm).Anwendung: Verbindet das Getriebe mit der Ballenpresse, dämpft Vibrationen.Why it's suitable: High-cycle durability, compatible with Bondioli & Pavesi.

10.4 Hydraulikzylinder:

Hydraulikzylinder: EP-HC-Serie (Bohrung 50-100 mm, Hub 300-600 mm), geeignet zum Anheben von Ballen.Lager und Dichtungen: Lager 6208-2RS, L10 Lebensdauer >10000 Stunden, staubdichte Dichtung.Kompatibilitätstabelle: Vollständig austauschbar mit Comer 250T (Drehmomentanpassung, nur 35% zum gleichen Preis); Flansch entspricht nordamerikanischem 4-Loch-Nebenabtriebsmuster.* Haftungsausschluss: Die oben genannten Markennamen dienen lediglich der Veranschaulichung. Wir bieten keine Originalprodukte oder -geräte dieser Marken an.* Die Parameter variieren je nach Betriebsbedingungen; bitte beachten Sie die tatsächlichen Zeichnungen. Es wird empfohlen, die Schnittstellenabmessungen vor der Auswahl zu bestätigen.

11. Frequently Asked Questions (FAQ)

Q1. What is the estimated price or cost of importing the 9YG-2.24D round baler to South Korea?

A1. The cost varies based on customization options, shipping rates to Incheon or Busan, and current exchange rates. However, as a direct manufacturer, we offer highly competitive factory-direct pricing that is significantly lower than European or Japanese alternatives. Please click "Get a Quote" for a specific CIF price tailored to your location.

Q2. Where can I find replacement parts and after-sales support for this baler in the Asian market?

A2. We have established a robust logistics network for spare parts. Common wear parts like pickup tines, rollers, and bearings are stocked and can be shipped via express courier to major Asian hubs within 3-5 days. We also provide detailed video maintenance guides and 24/7 technical support online.

Q3. How does the 9YG-2.24D handle wet rice straw or silage conditions compared to dry hay?

A3. This model excels in wet conditions due to its specialized "Axial Flow" semi-forced feeding mechanism. Unlike passive feeding systems that clog with wet, sticky rice straw, our dial tine rollers actively push the material into the chamber. It is specifically engineered to handle moisture content ideal for silage production without plugging.

Q4. Which tractor horsepower and PTO speed are required to operate this round baler efficiently?

A4. The 9YG-2.24D requires a tractor with a power range of 55-100 kW (approximately 75-135 HP). The standard PTO input speed is 720 r/min. Please ensure your tractor has the necessary hydraulic outputs and sufficient weight for safe towing on slopes.

Q5. How do I adjust the bale density when switching between different crop types like corn stalks and wheat straw?

A5. Density adjustment is simplified via our sensor-controlled system. You do not need to manually adjust complex springs. The system monitors the pressure within the chamber and triggers the binding process once the pre-set density (between 100-200 kg/m³) is achieved, ensuring consistent bale weight every time.

Q6. Can this machine be customized with specific hitches or hydraulic couplings for LS or Kubota tractors?

A6. Yes, we offer OEM customization services. We can adapt the hydraulic quick couplers, PTO splines, and drawbar hitch height to perfectly match specific tractor models popular in South Korea, such as LS Mtron, Daedong, or Kubota M-series, ensuring plug-and-play compatibility.

Q7. What warranty coverage is provided for the main components like the gearbox and compression rollers?

A7. We provide a comprehensive 1-year warranty on all main structural components, including the gearbox, chassis, and compression rollers. Our warranty covers manufacturing defects, and we prioritize the immediate dispatch of replacement parts to minimize any disruption to your harvesting operations.

Q8: How does the 9YG-2.24D Round Baler handle wet crops like silage compared to dry hay?

A8: The 9YG-2.24D is specially designed to handle wet crops, such as silage, with its Axial Flow Semi-Forced Feeding System. This system uses dial tine rollers that actively push wet, heavy crops into the compression chamber, ensuring smooth feeding without clogging. Unlike traditional balers, which struggle with wet crops, this model ensures optimal bale formation for silage, promoting better fermentation and reducing spoilage.

Q9: What maintenance is required for the 9YG-2.24D Round Baler?

A9: The 9YG-2.24D Round Baler is designed for low maintenance, thanks to its cam-less, guard-ring-less pickup system and durable construction. Regular checks include ensuring the chain tension is correct (every 10 hours of operation) and ensuring that the automatic oiling system is properly filled. For the Axial Flow Feeding System, keeping the rollers clean and lubricated is essential to ensure smooth operation. The 20A chains are heat-treated for durability, reducing wear and tear over time.

Q10: Can the 9YG-2.24D Round Baler be customized to fit different tractor models?

A10: Yes, the 9YG-2.24D is highly customizable. We offer OEM/ODM services to tailor the baler to your specific tractor model. Whether you need adjustments for hydraulic compatibility, PTO shaft modifications, or specific hitch types (like drawbar or 3-point hitch), we can modify the baler to ensure seamless integration with your tractor. We can also adjust the net wrap specifications and tire upgrades for different working conditions.

Ready to Upgrade Your Harvesting Efficiency?

Contact EVER-POWER today for a personalized quote and shipping details to South Korea.

Herausgeber: PXY