Beschreibung

1. 9GD-2.5 Technical Specifications

| NEIN. | Artikel | Einheit | Spezifikation |

|---|---|---|---|

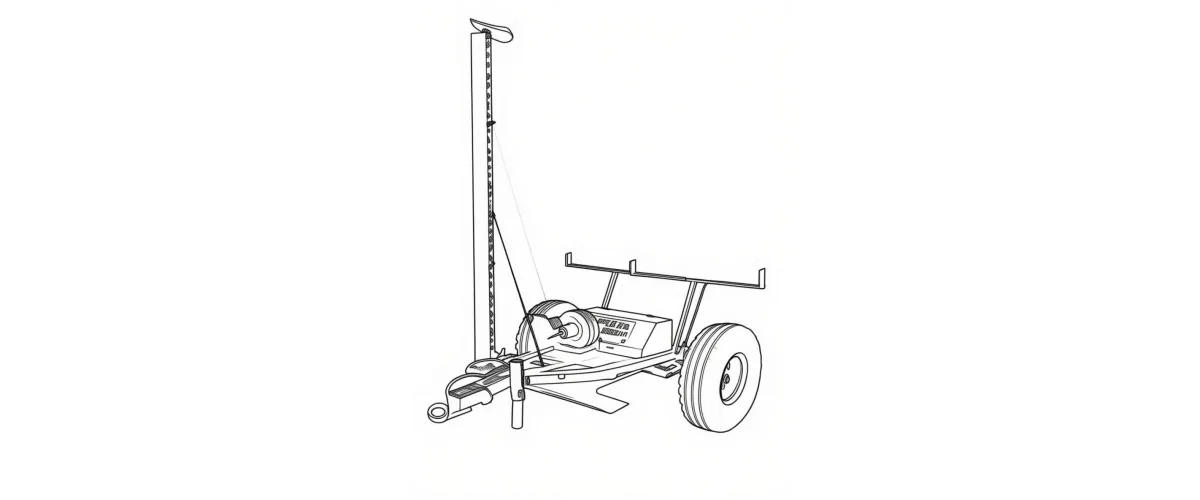

| 1 | Modellname | / | 9GD-2.5 Trailed Single-Blade Mower |

| 2 | Anhängertyp | / | Trailed |

| 3 | Schneidwerksstrukturtyp | / | Hin- und Herbewegung |

| 4 | Schnittbreite | M | 2.5 |

| 5 | Matching Power Range | kW | 15-35 |

| 6 | Arbeitsgeschwindigkeitsbereich | km/h | 6~10 |

| 7 | Anzahl der beweglichen Klingen | Stück | 34 |

| 8 | Dimensions (L × W × H) | mm | 2000×4300×950 |

| 9 | Drehzahl der Ausgangswelle | r/min | 540 |

| 10 | Durchschnittliche Schnitthöhe | mm | 50-70 |

| 11 | Produktivität | hm2/h | 2.0-3.0 |

| 12 | Number of Operators | (persons) | 1 |

| 13 | Structure Weight | kg | 490 |

2. Engineering Excellence: Principles and Scenarios

The working principle of the 9GD-2.5 relies on the mechanical conversion of rotational energy into high-speed linear reciprocating motion. The tractor’s PTO shaft transmits power to a primary drive pulley, which then activates the offset crank mechanism. This drives the cutter bar’s knives across stationary guards, creating a shearing effect similar to industrial scissors. This method is preferred in pasture management equipment in Korea because it minimizes soil disturbance and prevents the “shattering” of delicate forage leaves, preserving the nutritional content of the hay.

In terms of materials, the main frame is constructed from high-grade structural carbon steel, while the cutter bar features heat-treated manganese steel blades for exceptional wear resistance and impact durability against hidden field debris. This machine is optimized for various scenarios, including the management of natural mountain pastures, the harvesting of high-density planted forage, and even large-scale landscape maintenance in construction-reclaimed lands. Its towed configuration offers superior tracking and stability on uneven terrains compared to side-mounted alternatives, ensuring consistent cutting height across the entire 2.5-meter swath.

3. Universal Compatibility Matrix

| Tractor Brand | Compatibility Status | PTO Requirement |

|---|---|---|

| LS Mtron / TYM / Daedong | High (Standard 3-Point Hitch) | 540 RPM |

| Kubota / Yanmar | High (Category I & II) | 540 / 720 RPM |

| John Deere / New Holland | Full Integration Ready | Standard 6-Spline |

4. Regulatory Compliance & Land Management Laws

5. Market Trend Analysis: The Future of Forage Harvesting

6. EVER-POWER-Werk: Kundenspezifische Anpassung & Qualitätssicherung

Unser Produktionswerk befindet sich in der Wirtschaftsentwicklungszone Hulunbuir und erstreckt sich über 32.000 Quadratmeter Wir sind mit modernsten CNC-Laserschneidmaschinen, automatischen Schweißanlagen und elektrostatischen Pulverbeschichtungsanlagen ausgestattet. Wir sind nicht nur ein Montagebetrieb, sondern ein Komplettanbieter mit umfassenden Forschungs- und Entwicklungskapazitäten.

Anpassungsdienstleistungen (OEM/ODM): Wir verstehen, dass die landwirtschaftlichen Bedingungen je nach Region variieren. Für den südkoreanischen Markt bieten wir unter anderem folgende Anpassungsmöglichkeiten an:

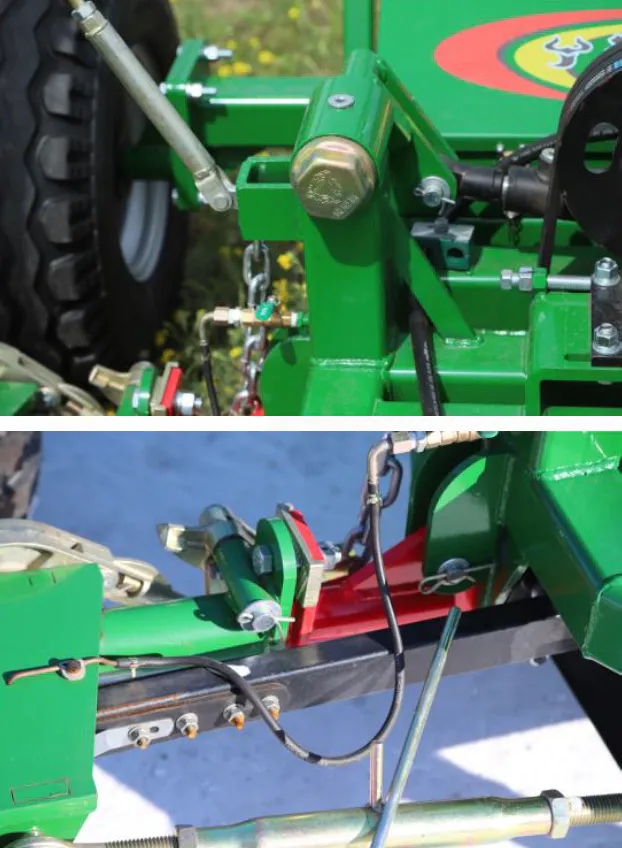

• Hydraulische Anpassung: Ventildrücke an die spezifischen Hydraulikflüsse von LS- oder Daedong-Traktoren anpassen.

• Reifen-Upgrades: Optionale breitere Breitreifen für tief schlammige Reisfelder.

• Farbe & Branding: OEM-Branding-Services für Händler und Distributoren.

Wir halten ISO9001 Qualitätsmanagementsystem-Zertifizierung und wurden als nationales Hightech-Unternehmen anerkannt. Jede Ballenpresse des Typs 9YG-2.24D wird vor dem Versand einem strengen 48-stündigen Dauerbetriebstest unterzogen, um sicherzustellen, dass sie bei der Ankunft fehlerfrei ist.

7. Verwandte Produkte

7.1 Getriebe:

Kompatible Modelle: EP-FK263 (Quaderballenpresse), EP-RC30-Serie (Rundballenpresse, Übersetzungsverhältnis 1:2, kompatibel mit 35-mm-6-Zahn-Welle).Anwendung: Überträgt Zapfwellenleistung auf die Ballenpresse, geeignet für New Holland 630 oder John Deere 535. Parameter: Drehmoment > 500 Nm, Kraftstoffersparnis 20%.Warum dieses Getriebe wählen? Anpassbare Größe (reduzierbar auf 250–300 mm), beständig gegen viskose Verunreinigungen (Gummidämpfe), Schutzart IP65. Zapfwelle:Kompatible Modelle: EP-PTO-Serie (1-3/8″ Z6-Keilwelle, einstellbare Länge 600-1200 mm).Anwendung: Verbindet Traktor mit dem Hauptantrieb der Ballenpresse, geeignet für Typ 9YG-1.0C. Drehmomentübertragungseffizienz >95%, kompatibel mit SAE/EURO-Flanschen.Warum es geeignet ist: Wasserdichtes Design, geeignet für Nasssilage-Einsätze; austauschbar mit der Weasler-Serie.

7.2 Ketten & Kettenräder:

Kompatible Modelle: ANSI Ketten, mit EP-Kettenrad (Teilung 12,7-19,05 mm, Rollendurchmesser 10-12 mm).Anwendung: Einsatz in Förderbändern oder Bindemechanismen, geeignet für den Transport von Stroh in Quader-/Rundballenpressen. Breite 25–40 mm, verschleißfestes Stahlmaterial.Warum es geeignet ist: Kompatibel mit Geräten von Kobelco oder der HF Group, verringert das Risiko von Kettenbrüchen; eine lebensmitteltaugliche Variante für Silage ist erhältlich.

7.3 Kupplungen:

Kompatible Modelle: EP-Kupplung Serie 200 (Drehmomentanpassung 500-1000 Nm).Anwendung: Verbindet das Getriebe mit der Ballenpresse, dämpft Vibrationen.Warum es geeignet ist: Hohe Zyklenfestigkeit, kompatibel mit Bondioli & Pavesi.

7.4 Hydraulikzylinder:

Hydraulikzylinder: EP-HC-Serie (Bohrung 50-100 mm, Hub 300-600 mm), geeignet zum Anheben von Ballen.Lager und Dichtungen: Lager 6208-2RS, L10 Lebensdauer >10000 Stunden, staubdichte Dichtung.Kompatibilitätstabelle: Vollständig austauschbar mit Comer 250T (Drehmomentanpassung, nur 35% zum gleichen Preis); Flansch entspricht nordamerikanischem 4-Loch-Nebenabtriebsmuster.* Haftungsausschluss: Die oben genannten Markennamen dienen lediglich der Veranschaulichung. Wir bieten keine Originalprodukte oder -geräte dieser Marken an.* Die Parameter variieren je nach Betriebsbedingungen; bitte beachten Sie die tatsächlichen Zeichnungen. Es wird empfohlen, die Schnittstellenabmessungen vor der Auswahl zu bestätigen.

8. Frequently Asked Questions (FAQ)

Q1: How much does the 9GD-2.5 Towed Single-Blade Lawn Mower cost for delivery to Busan port?

A1: The **Reciprocating cutter bar mower price** for the 9GD-2.5 varies based on order volume and customization. Generally, for a single unit, the price is highly competitive for the Korean market. To get an exact quote including shipping and insurance to Busan or Incheon, please click our ‘Get a Quote’ button to speak with a sales representative.

Q2: Where can I find a reliable Towed Single-Blade Lawn Mower manufacturer that ships directly to South Korea?

A2: Jiujia Machinery is a direct-to-market manufacturer with extensive experience exporting to the South Korean agricultural sector. We handle all international logistics and provide direct factory support for the 9GD series, ensuring you avoid middleman markups while receiving genuine industrial-grade equipment.

Q3: What is the recommended tractor horsepower for operating the 9GD-2.5 lawn mower on sloped pastures?

A3: For the 9GD-2.5 model, the optimal power requirement is between 25 and 40 HP (18.4-30 kW)[cite: 1]. If you are operating in sloped regions like the Gangwon highlands, we recommend using a tractor at the higher end of that range (35-40 HP) to ensure consistent PTO speed and towing stability.

Q4: Which reciprocating blade material is best for high-moisture sudangrass harvesting in Korea?

A4: We utilize heat-treated manganese steel for all 9GD-2.5 cutter bars. This material is specifically chosen for its ability to maintain a sharp edge even when cutting high-moisture forage, preventing the “clogging” that often occurs with standard carbon steel blades in humid Korean summers.

Q5: How do I choose between the 9GD-2.5 and the upgraded version for my farm’s specific needs?

A5: The standard 9GD-2.5 is designed for maximum cost-efficiency and reliability using a traditional crank-rod system. [cite_start]If your priority is a proven, high-productivity workhorse (up to 2.0 hm²/h) [cite: 1] with simpler maintenance requirements, the standard 9GD-2.5 is the ideal choice for most commercial forage farms.

Q6: What are the maintenance requirements for the crank mechanism in the 9GD-2.5 lawn mower?

A6: To ensure longevity, the primary maintenance task is daily lubrication of the crank pin and connecting rod bearings. We also recommend checking the tension of the drive belt every 20 operational hours. [cite_start]These simple steps prevent mechanical wear and ensure your machine maintains its 5-8 km/h working speed[cite: 1].

Q7: Does Jiujia offer product customization for different tractor hitch standards used in Korea?

A7: Yes! While the 9GD-2.5 comes with a standard towed hitch, we can customize the connection points to match specific LS Mtron or Daedong tractor standards. We can also adjust the PTO spline configuration to ensure a seamless “plug-and-play” experience for your existing fleet.

Q8: When is the best time to replace the cutter bar guards on the 9GD-2.5?

A8: Guards should be inspected every season. If you notice a “tearing” rather than a “cutting” of the grass, or if the stationary edges have become rounded, it is time for a replacement. [cite_start]Maintaining sharp guards ensures you stay within the 30-80 mm cutting height range effectively[cite: 1].

Q9: What safety certifications does the 9GD-2.5 hold for international agricultural equipment markets?

A9: Our equipment is manufactured under ISO 9001 quality management systems and meets the essential safety requirements for international agricultural trade. We provide full technical documentation to assist with South Korean MAFRA safety audits and insurance requirements.

Q10: Why should I choose a towed single-blade mower over a standard rotary mower for livestock feed?

A10: Towed single-blade mowers use a reciprocating cut that preserves the stem’s vascular structure. This results in significantly higher forage quality and faster field drying times compared to rotary mowers, which can “beat” the grass and cause sap loss, especially in high-sugar crops like alfalfa.

Herausgeber: PXY

*Hinweis: Die oben genannten Markennamen dienen lediglich der Veranschaulichung. Wir bieten keine Originalprodukte oder -geräte dieser Marken an.