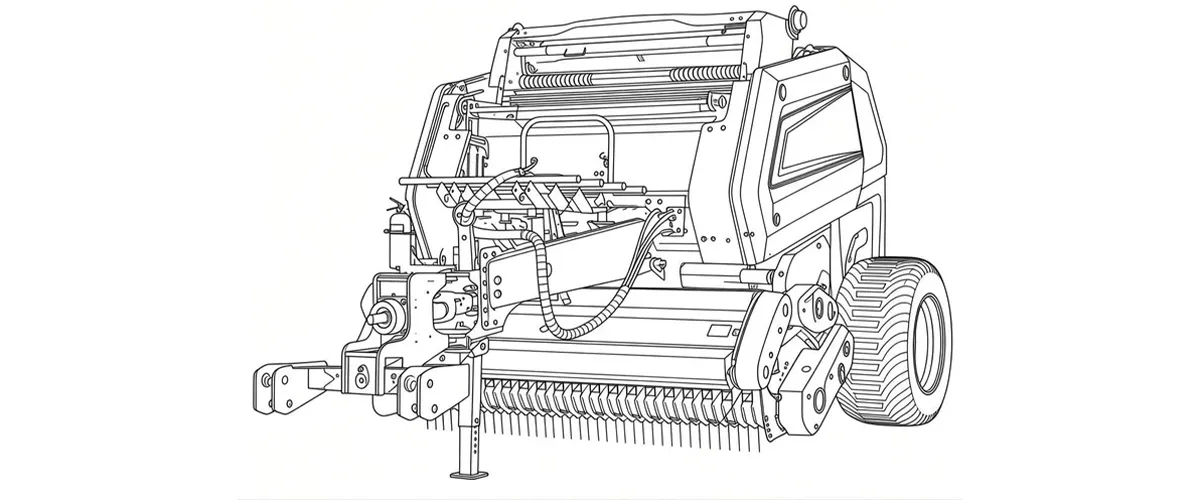

EP-9YG-1.25A Round Baler

1. Technical Specifications: 9YG-1.25A Round Baler

Item / Feature Unit Specification (9YG-1.25A) Hitch Type - Trailed (Traction Type) Pickup Width mm 2150 Feeding Mechanism - Auger + Dial Tooth Roller + Roller Chamber Dimensions (W x D) mm 1250 x Φ1200 Compression Rollers Qty / Dia 18 Units / Φ222 mm Matched Power kW ≥ 75 Structure Weight kg 4472 PTO Speed r/min 540 - 1000 Overall Dimensions (Work) mm 4400 × 2850 × 2400 Bale Density kg/m³ 100 - 200 (Sensor Controlled) Productivity Bales/h 40 ~ 100 Binding Type - Net Binding (2000 x 1.25m/roll)

2. Key Engineering Facts

- Chamber Technology: Features a fixed chamber with 18 high-strength steel rollers (Φ222mm) for non-stop rotation and maximum compaction.

- High Productivity: Capable of producing up to 100 bales per hour with a density reaching 200 kg/m³, ideal for fermentation quality in silage.

- Wide Intake: The 2150mm pickup width accommodates wide swathes from modern combine harvesters, reducing field passes.

- Power Efficiency: Requires a tractor power range of ≥75 kW, optimizing fuel usage while delivering high torque through the 540/1000 r/min PTO.

- Advanced Feeding: Utilizes a specialized "Auger + Dial Tooth Roller + Roller" feeding structure to prevent clogging in wet or heavy crops.

3. Working Principle, Materials & Application Scenarios

3.1 Advanced Roller Compression Technology

The core operational advantage of the 9YG-1.25A lies in its 18-roller fixed chamber design, which offers superior reliability over belt-type balers in abrasive or wet conditions.

The working principle begins with the 2150mm wide spring-tooth pickup mechanism, which lifts the crop (straw, hay, or silage) from the windrow. The crop is then actively fed into the chamber via a dynamic "Auger + Dial Tooth Roller" system. This semi-forced feeding mechanism is critical for preventing blockages, a common issue when harvesting damp rice straw in the Korean climate. Once inside the chamber, the 18 steel rollers, driven by heavy-duty chains, rotate to tumble the crop into a tight cylindrical shape. As more material enters, the density increases from the core outwards. Unlike belt balers that rely on tension arms, the steel rollers provide mechanical compression that does not falter under the high pressure required for silage (up to 200 kg/m³). When the pre-set density is reached, the sensor triggers the automatic net binding system, wrapping the bale securely in seconds before ejection.

3.2 Material Metallurgy & Durability

Durability is non-negotiable for agricultural machinery operating in the demanding terrains of East Asia and North America; therefore, EVER-POWER utilizes premium-grade metallurgy.

The 18 compression rollers are fabricated from high-strength alloy steel, treated to resist the abrasive nature of silica-rich crops like rice straw. The chassis is constructed from reinforced structural steel to withstand the torsional stresses of traversing uneven paddy fields or hilly pastures. Crucially, the drive system features upgraded heavy-duty chains (comparable to 20A industrial standards), which are essential for transferring the high torque required to compress dense bales without stretching or snapping. The gears and sprockets undergo advanced heat treatment (carburizing and quenching) to achieve a surface hardness of HRC 58-62, ensuring longevity even under continuous maximum-load operation. The surface finish involves electrostatic powder coating, providing superior corrosion resistance against humid environments and fertilizers.

3.3 Global & Local Application Scenarios

The 9YG-1.25A is engineered to be a versatile workhorse, adaptable to specific regional agricultural practices and crop types.

In South Korea, the primary application is the collection of rice straw immediately following the harvest. Korean farmers face a narrow window between harvest and winter; this baler's high speed and ability to handle slightly damp straw make it indispensable for producing "Whole Crop Rice Silage" (WCS) for the beef industry. In North America and Europe, the machine excels in haylage production and corn stalk baling for biomass energy or animal bedding. Its high density is particularly valued here for reducing transport logistics costs. Furthermore, in nations like Russia and Mongolia, where vast pasturelands require equipment that can endure rough terrain, the trailed design with a wide wheel track (2450mm) offers exceptional stability. The machine is also fully capable of handling alfalfa, wheat straw, and soybean residue, making it a comprehensive solution for mixed-farming operations.

4. Global Regulatory Compliance & Land Management

Compliance with environmental regulations regarding crop residue management is a critical driver for the adoption of high-performance balers like the 9YG-1.25A.

- South Korea (Fine Dust Management): The Korean government actively enforces strict bans on open field burning of agricultural residues to combat severe air pollution and fine dust issues. The Wastes Control Act and local ordinances mandate proper disposal or utilization of rice straw. The 9YG-1.25A enables farmers to comply by efficiently converting what was once waste into valuable livestock feed or biomass fuel, often qualifying for government subsidies for eco-friendly farming equipment.

- European Union (CAP): Under the Common Agricultural Policy (CAP), farmers are incentivized to maintain soil organic matter and reduce carbon emissions. Baling straw for renewable energy or bedding, rather than burning, aligns with cross-compliance standards required for EU subsidies.

- China (Blue Sky Defense War): Similar to Korea, China imposes rigorous penalties for straw burning. The Ministry of Agriculture promotes the comprehensive utilization of straw (fertilizer, feed, fuel), creating a massive demand for reliable balers that can clear fields quickly to facilitate crop rotation.

5. Market Trend Analysis: The Shift to High-Density Baling

Firstly, the "Silage Revolution" in Asia continues to grow. Traditional dry hay baling is being supplemented by high-moisture silage baling (WCS), which requires balers that can handle heavy, wet crops without jamming. The roller-type compression of the 9YG-1.25A is technically superior for this application compared to belt balers, which often struggle with wet adhesion.

Secondly, Speed and Automation are non-negotiable. The transition from twine to net binding, featured in this model, is a dominant trend. Net binding reduces the wrapping cycle from minutes to seconds, protects the bale shape better against the weather, and is easier to remove for feeding. EVER-POWER aligns with these trends by offering a machine that balances high-tech performance with the durability required for intensive seasonal work.

6. Application Scenarios

6.1. Large-Scale Grain Plantations

In vast farmlands, especially for major crops such as wheat, corn, and rice, round balers help quickly collect and bundle straw into round or square bales, facilitating easy storage, transport, and further processing after harvest.

6.2. Pasture Farming & Feed Production

Round balers are used in large-scale grass plantations, particularly for hay and silage collection. They efficiently bundle large amounts of grass, providing high-quality feed for livestock.

6.3. Biomass Power Plants

In biomass energy production, round balers efficiently collect and bundle agricultural residues such as straw and corn stalks, reducing transportation costs while supplying raw materials for biomass power generation.

6.4. Straw Management on Large Farms

On large, modernized farms, especially for wheat, corn, and other crops, round balers are used to manage crop residues. With the increasing environmental restrictions on straw burning, balers help reduce pollution by efficiently bundling and storing straw.

6.5. Soybean and Other Small Grain Crop Residue Collection

For soybean and other small grain crops, round balers are used to collect straw and other residue post-harvest. These residues are then processed into valuable products like animal feed, bedding, or compost.

6.6. Wind Farm Grassland Maintenance

Wind farms are often located in large pasturelands or wastelands. Round balers play a key role in maintaining these areas by collecting grass, which can be used as feed for livestock or for energy production.

6.7. Agricultural Waste Recycling

On large-scale farms, agricultural waste can be processed using round balers, converting it into useful products like animal feed, compost, or biomass fuel, supporting a circular economy while reducing waste.

6.8. Crop Straw Compression and Storage on Large Farms

For large farms growing rice, wheat, and other staple crops, round balers help compress crop straw into high-density bales, making it easier to store, transport, or utilize as fuel or bedding.

6.9. Agriculture-Livestock Integrated Enterprises

Large agriculture-livestock integrated enterprises often combine crop production and animal husbandry. Round balers are used to efficiently collect crop residues, which are then converted into feed or energy, providing a sustainable cycle for farming operations.

6.10. Greenhouse Agricultural Waste Collection and Recycling

In greenhouse agriculture, round balers not only handle traditional crops but also collect waste materials like wilted plants and leftover grass. These materials are then processed into useful products like compost, animal bedding, or biomass fuel.

7. Component & Tractor Compatibility

| Feature | EVER-POWER 9YG-1.25A | Standard Competitor / Compatibility Notes |

|---|---|---|

| Tractor HP Requirement | ≥ 75 kW (approx. 100+ HP) | Compatible with John Deere 6M Series, Kubota M-Series, LS Tractor MT7 (Korea) |

| PTO Connection | Standard 6-Spline / 8-Spline (540/1000 RPM) | Universal Interface (ISO Standard); Adaptable to most global tractor brands. |

| Net Wrap System | 1.25m Standard Net | Compatible with generic net wraps (Tama, Novatex, etc.) widely available in local markets. |

| Hydraulic Output | 2 Double Acting Valves required | Uses Standard H-type hydraulic couplers for fast connection. |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

8. Client Success Story:

"We’ve been using the 9YG-1.25A for several seasons now, and I can confidently say it’s a game-changer. The 2150mm pickup width really makes a difference, and it’s so efficient at collecting rice straw even when it’s slightly damp. The net binding system is quick, and the bales hold their shape even after being moved multiple times. Definitely worth the investment!"

---John from South Korea

"The 9YG-1.25A is perfect for our biomass operations. We use it to collect corn stover and straw for biofuel production. The bale density is outstanding, and we’ve noticed a significant reduction in our logistics costs. Plus, the automatic net binding system speeds up our operation. Very happy with its performance!"

--- Carlos, Bioenergy Project Manager in Spain

"This baler is a powerhouse! We’ve had it on our farm for over a year now, handling everything from alfalfa to wheat straw. The auger and dial tooth roller feeding system is fantastic, preventing blockages and ensuring a smooth flow of material. Plus, it's built to take on the tough, rocky terrain of our farm without missing a beat."

--- Liam from Australia

"We’ve been recommending the 9YG-1.25A to our clients, especially those looking for high-efficiency balers that don’t break the bank. It’s been a huge success for silage production, particularly in wetter conditions. It’s simple to operate and the build quality is excellent. The 540/1000 RPM PTO speed is flexible and suits most tractors in the field."

---David, Farm Equipment Dealer in the UK

"I’ve been using the 9YG-1.25A for hay and silage, and it’s honestly the best baler I’ve used. The 100-200 kg/m³ bale density is perfect for us, and the fact that the machine can handle crops without clogging is a huge bonus. It’s easy to maintain, and I’ve noticed a reduction in downtime. A solid choice for any large-scale farm!"

---Jack, Livestock Farmer in Canada

9. Factory Capabilities & Customization Services

At EVER-POWER, we do not just assemble machines; we engineer solutions tailored to your specific agricultural environment.

With a manufacturing footprint of over 32,000 square meters and a dedicated R&D center, we offer extensive OEM and ODM services. We understand that a baler operating in the dry plains of Australia has different needs than one in the humid paddies of Vietnam.

- Color Customization: Match your fleet branding (e.g., John Deere Green, Case IH Red).

- Hitch Adaptation: Custom drawbars to fit specific tractor linkages used in your region.

- Hydraulic Tuning: Adjustment of hydraulic pressure valves to match your tractor's flow rate.

- Material Upgrades: Option to upgrade to specialized wear-resistant steel for abrasive soil conditions.

Our facility is ISO9001 certified, ensuring that every 9YG-1.25A unit undergoes rigorous static and dynamic testing before shipment. We invite global partners to collaborate with us for localized agricultural equipment solutions.

10. Related products

10.1 Gearbox:

Compatible models: EP-FK263 (square baler), EP-RC30 series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:Compatible Models: EP-PTO series (1-3/8" Z6 spline, adjustable length 600-1200mm).Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.Why it's suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.10.2 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.Why it's suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.10.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.Why it's suitable: High-cycle durability, compatible with Bondioli & Pavesi.10.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.* Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.* Parameters vary depending on working conditions; please refer to the actual drawings. It is recommended to confirm interface dimensions before selection.

11. Related products

11.1 Gearbox:

Compatible models: EP-FK263 (square baler), EP-RC30 series (round baler, transmission ratio 1:2, compatible with 35mm 6-spline shaft).Application: Transmits PTO power to the baling mechanism, suitable for New Holland 630 or John Deere 535. Parameters: Torque > 500 Nm, 20% fuel saving.Why choose this gearbox: Customizable size (reducible to 250-300mm), resistant to viscous contaminants (rubber fumes), IP65 protection. PTO Shaft:Compatible Models: EP-PTO series (1-3/8" Z6 spline, adjustable length 600-1200mm).Application: Connects tractor to baler main drive, suitable for 9YG-1.0C type. Torque transmission efficiency >95%, compatible with SAE/EURO flanges.Why it's suitable: Waterproof design, suitable for wet silage operations; replaceable with Weasler series.11.2 Chains & Sprockets:

Compatible Models: ANSI #50/#60 chains, with EP-Sprocket (pitch 12.7-19.05mm, roller diameter 10-12mm).Application: Used in conveyor belts or binding mechanisms, suitable for square/round baler straw conveying. Width 25-40mm, wear-resistant steel material.Why it's suitable: Compatible with Kobelco or HF Group equipment, reduces chain breakage risk; food-grade option available for silage.11.3 Couplings:

Compatible Models: EP-Coupling 200 series (torque matching 500-1000 Nm).Application: Connects gearbox to baling roller, dampens vibration.Why it's suitable: High-cycle durability, compatible with Bondioli & Pavesi.11.4 Hydraulic Cylinder:

Hydraulic Cylinder: EP-HC series (bore 50-100mm, stroke 300-600mm), suitable for bale lifting.Bearings and Seals: 6208-2RS bearings, L10 life >10000 hours, dustproof seal.Compatibility Table: Fully interchangeable with Comer 250T (torque matching, only 35% of the price); flange matches North American 4-Bolt PTO Pattern.* Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.* Parameters vary depending on working conditions; please refer to the actual drawings. It is recommended to confirm interface dimensions before selection.

11. FAQ

Q1. How does the price of the 9YG-1.25A baler compare to European brands like Claas or Kuhn delivered to South Korea?

A1. The EVER-POWER 9YG-1.25A is engineered to offer a competitive edge, typically priced at approximately 35-40% of the cost of comparable European models like Claas or Kuhn. Despite the lower cost, we utilize high-grade alloy steel rollers and heavy-duty 20A chains that match western performance standards. For delivery to South Korean ports like Busan or Incheon, our proximity allows for significantly lower shipping costs and faster lead times compared to European suppliers.

Q2. What is the minimum tractor horsepower required to operate this round baler efficiently in hilly terrains?

A2. While the technical specification lists a minimum requirement of 75 kW (approx. 100 HP), for hilly terrains often found in Jeolla or Gangwon provinces, we recommend a tractor with at least 110-120 HP. This ensures sufficient power reserve for both the PTO drive to compress high-density bales and the traction required to tow the 4472 kg unit up inclines without straining the engine.

Q3. Can this baler handle wet rice straw for silage production without clogging the feeding mechanism?

A3. Absolutely. This is a key feature of the 9YG-1.25A. It utilizes a specialized "Auger + Dial Tooth Roller + Roller" feeding system specifically designed for "semi-forced" feeding. This active feeding mechanism aggressively grabs wet, slippery rice straw and forces it into the chamber, virtually eliminating the blockage issues common with passive pickup systems found on older models.

Q4. Where can I purchase spare parts like pickup tines or roller bearings if I am located in Gyeonggi-do?

A4. We have established a robust logistics network. For common consumables like pickup tines (spring teeth) and bearings, we can ship directly via international courier to Gyeonggi-do within 3-5 days. Furthermore, we provide a "Critical Spare Parts Kit" with every machine purchase, and many components (like bearings and chains) utilize standard ISO specifications, meaning compatible replacements can often be sourced locally in Korea.

Q5. Which binding material does the 9YG-1.25A use, and is it compatible with standard Korean agricultural nets?

A5. The 9YG-1.25A uses an automatic Net Binding system. It is fully compatible with standard agricultural net rolls sized at 1.25m width (2000m length per roll), which are widely available in the Korean market. The net binding system is generally preferred over twine for silage as it provides better coverage, maintains bale shape better during wrapping, and is faster to apply.

Q6. How do I maintain the 18-roller compression chamber to ensure long-term durability?

A6. Maintenance is straightforward. The most critical step is regular lubrication of the chain drive system and roller bearings using high-quality grease, especially after washing the machine. Since the rollers are steel (not rubber belts), they do not require tension adjustment, but you should visually inspect the scraper gaps to prevent material buildup. We provide a detailed English/Korean maintenance manual with every unit.

Q7. Does EVER-POWER offer customization for the hitch system to fit my specific tractor model?

A7. Yes, as an OEM manufacturer, we offer customization services. If your tractor utilizes a specific drawbar height or hydraulic coupling standard different from our default configuration, please specify this during the inquiry process. We can modify the traction head and hydraulic interfaces to ensure a "plug-and-play" experience upon delivery to your farm.

Q8. What is the typical lead time for a container order of these balers to the USA or Australia?

A8. For standard orders, our production lead time is typically 15-20 days. Shipping times vary by destination; for the West Coast of the USA or major Australian ports, ocean freight usually takes an additional 20-30 days. We recommend placing orders 2 months prior to the harvest season to ensure timely arrival and setup.

Q9. How does the "floating" pickup protection feature work when encountering rocks or obstacles?

A9. The 9YG-1.25A features a specialized hydraulic suspension for the pickup reel. When the pickup tines encounter a rigid obstacle like a rock or tree root, the mechanism allows the pickup unit to "float" or lift automatically to clear the obstacle, then immediately return to the working height. This prevents damage to the tines and the main rotor, significantly reducing downtime and repair costs.

Q10. Is it possible to visit the factory in China to inspect the baler production line before ordering?

A10. We warmly welcome all potential partners and clients to visit our manufacturing facility. We believe in transparency and quality. You can inspect our laser cutting workshops, robotic welding lines, and assembly processes. Please contact our sales team to schedule a visit, and we can assist with invitation letters and local travel arrangements.

Ready to Upgrade Your Harvest Efficiency?

Contact EVER-POWER today for a customized quote and technical consultation.

Email: [email protected]

Editor: PXY